12

AIR

DISCHARGE

AIR

DISCHARGE

AIR

DISCHARGE

Bottom

Return

Duct

Connection

Bottom

Return

Duct

Connection

Bottom

Return

Duct

Connection

Side

Return

Duct

Connection

Side

Return

Duct

Connection

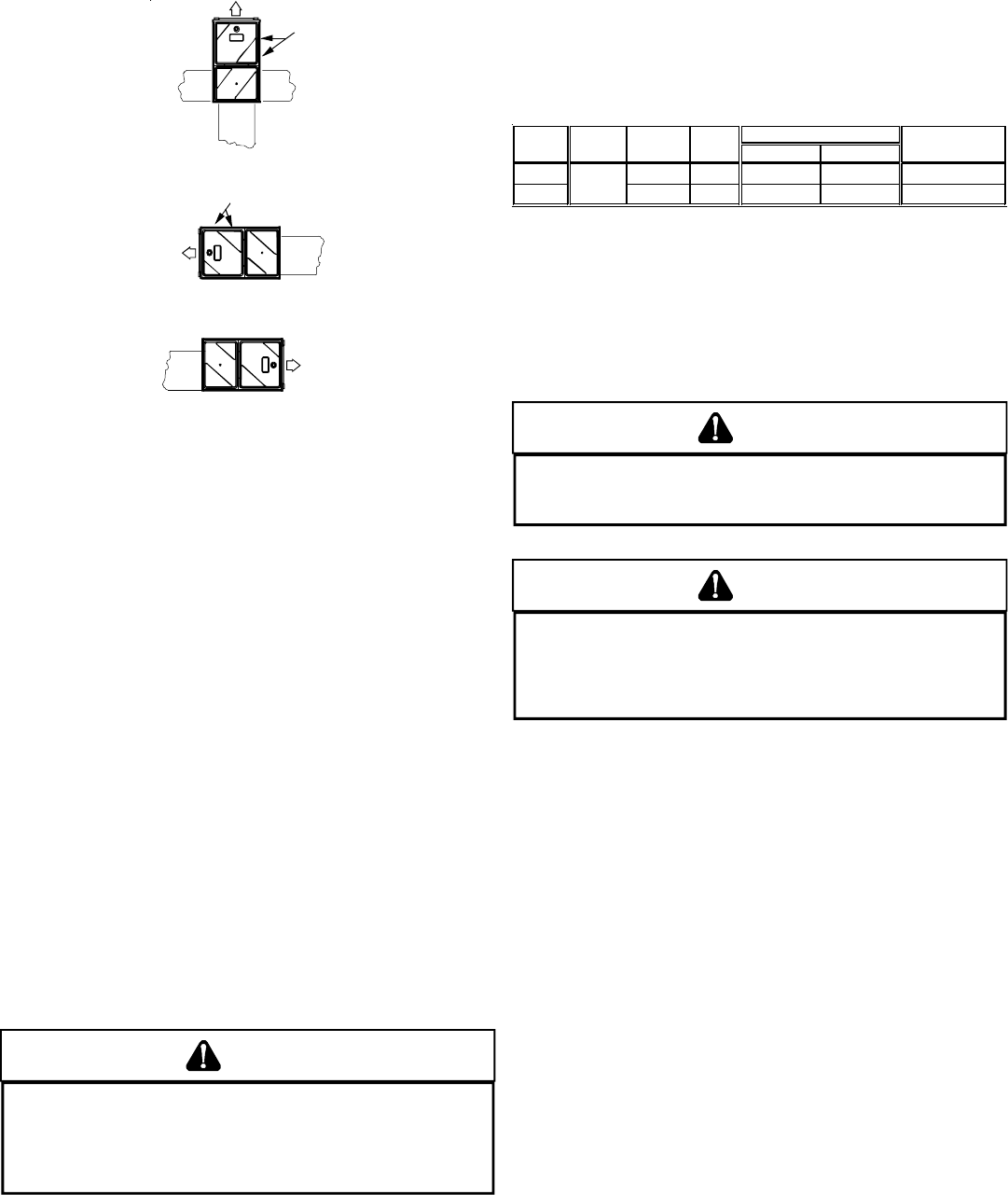

UPFLOW

UPRIGHT

UPFLOW HORIZONTAL

RIGHT AIR DISCHARGE

UPFLOW HORIZONTAL

LEFT AIR DISCHARGE

ALTERNATE FLUE AND

COMBUSTION AIR PIPE

LOCATIONS

ALTERNATE FLUE AND

COMBUSTION AIR PIPE

LOCATIONS

Recommended Installation Positions

NOTE: Alternate “vertical” piping connections can not be used when

an upflow furnace is installed with supply air discharging to the

right, or when a counterflow furnace is installed with supply air

discharging to the left. In either case, use the standard flue and

combustion air piping connections.

ALTERNATE E LECTRICAL AND G AS L INE C ONNECTIONS

This furnace has provisions allowing for electrical and gas line

connections through either side panel. In horizontal applications

the connections can be made either through the “top” or “bottom” of

the furnace.

DRAIN PAN

A drain pan must be provided if the furnace is installed above a

conditioned area. The drain pan must cover the entire area under

the furnace (and air conditioning coil if applicable).

FREEZE P ROTECTION

Refer to Section VI, Horizontal Applications and Conditions - Drain

Trap and Lines.

FURNACE S USPENSION

If the furnace is installed in a crawl space it must be suspended

from the floor joist or supported by a concrete pad. Never install the

furnace on the ground or allow it to be exposed to water. Refer to

Section IV, Location Requirements and Considerations - Furnace

Suspension for further details.

VIII. PRVIII. PR

VIII. PRVIII. PR

VIII. PR

OO

OO

O

PP

PP

P

ANE GAANE GA

ANE GAANE GA

ANE GA

S /HIS /HI

S /HIS /HI

S /HI

GH ALGH AL

GH ALGH AL

GH AL

TITUDTITUD

TITUDTITUD

TITUD

E INSTE INST

E INSTE INST

E INST

ALLALL

ALLALL

ALL

AA

AA

A

TITI

TITI

TI

OO

OO

O

NSNS

NSNS

NS

WARNING

P

OSSIBLE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH MAY OCCUR IF

THE CORRECT CONVERSION KITS ARE NOT INSTALLED.

T

HE APPROPRIATE KITS

MUST BE APPLIED TO INSURE SAFE AND PROPER FURNACE OPERATION.

A

LL

CONVERSIONS MUST BE PERFORMED BY A QUALIFIED INSTALLER OR SERVICE

AGENCY.

This furnace is shipped from the factory configured for natural gas

at standard altitude. Propane gas installations require an orifice

change to compensate for the energy content difference between

natural and propane gas.

High altitude installations may require both a pressure switch and

an orifice change. These changes are necessary to compensate

for the natural reduction in the density of both the gas fuel and the

combustion air at higher altitude.

For installations above 7000 feet, please refer to your distributor

for required kit(s).

High Stage Low Stage

Natural None #43 3.5" w.c. 1.9" w.c. None

Propane

LPM-03B

#55 10.0" w.c. 6.0" w.c. None

Orifice

NOTE

:

I

n

C

ana

d

a, gas

f

urnaces are on

l

y cer

tifi

e

d

t

o

4500

f

ee

t

.

0-7000

Manifold Pressure Pressure

Switch Change

Gas Altitude Kit

Contact the distributor for a tabular listing of appropriate

manufacturer’s kits for propane gas and/or high altitude installa-

tions. The indicated kits must be used to insure safe and proper

furnace operation. All conversions must be performed by a quali-

fied installer, or service agency.

IX. VENT/FLUE PIPE & COMBUSTION AIR PIPEIX. VENT/FLUE PIPE & COMBUSTION AIR PIPE

IX. VENT/FLUE PIPE & COMBUSTION AIR PIPEIX. VENT/FLUE PIPE & COMBUSTION AIR PIPE

IX. VENT/FLUE PIPE & COMBUSTION AIR PIPE

GENERAL

WARNING

F

AILURE TO FOLLOW THESE INSTRUCTIONS CAN RESULT IN BODILY INJURY OR

DEATH.

C

AREFULLY READ AND FOLLOW ALL INSTRUCTIONS GIVEN IN THIS

SECTION.

WARNING

U

PON COMPLETION OF THE FURNACE INSTALLATION, CAREFULLY INSPECT THE

ENTIRE FLUE SYSTEM BOTH INSIDE AND OUTSIDE THE FURNACE TO ASSURE IT

IS PROPERLY SEALED.

L

EAKS IN THE FLUE SYSTEM CAN RESULT IN SERIOUS

PERSONAL INJURY OR DEATH DUE TO EXPOSURE TO FLUE PRODUCTS,

INCLUDING CARBON MONOXIDE.

A condensing gas furnace achieves its high level of efficiency by

extracting almost all of the heat from the products of combustion

and cooling them to the point where condensation takes place.

Because of the relatively low flue gas temperature and water con-

densation requirements, PVC pipe is used as venting material.

This furnace must not be connected to Type B, BW, or L vent or vent

connector, and must not be vented into any portion of a factory built

or masonry chimney except when used as a pathway for PVC as

described later in this section. Never common vent this appliance

with another appliance or use a vent which is used by a solid fuel

appliance. Do not use commercially available “no hub connec-

tors” other than those shipped with this product.

It is the responsibility of the installer to follow the manufacturers’

recommendations and to verify that all vent/flue piping and connec-

tors are compatible with furnace flue products. Additionally, it is the

responsibility of the installer to ensure that all piping and connec-

tions possess adequate structural integrity and support to prevent

flue pipe separation, shifting, or sagging during furnace operation.

DUAL CERTIFICATION: NON-DIRECT/DIRECT V ENT

This furnace is dual certified and may be installed as a non-direct

vent (single pipe) or direct vent (dual pipe) appliance. A non-direct

vent installation requires only a vent/flue pipe, while a direct vent

installation requires both a vent/flue pipe and a combustion air

intake pipe. Refer to the appropriate section for details concerning

piping size, length, number of elbows, furnace connections, and

terminations.