35

Please Do Not Return This Product To The Store. Contact your local Wayne-Dalton dealer. To find your local Wayne-Dalton dealer, refer to your

local yellow pages/business listings or go to the Find a Dealer section online at www.wayne-dalton.com

Tools Needed:

�

OPTIONAL INSTALLATION

Trolley Operator

OPERATOR MUST BE TESTED

AT TIME OF INSTALLATION AND

MONTHLY THEREAFTER TO

ENSURE THAT DOOR REVERSES

ON CONTACT WITH 2 X 4 BOARD

LAID FLAT UNDER THE DOOR.

FAILURE TO ADJUST OPERATOR,

IF NECESSARY, CAN RESULT IN

SEVERE OR FATAL INJURY. IF

YOUR OPERATOR IS EQUIPPED

WITH A PHOTOELECTRIC EYE

SYSTEM, THEN THIS MUST

BE TESTED AT THE SAME

TIME TO ENSURE THAT DOOR

DOES NOT CLOSE AND A

CLOSING DOOR OPENS IF

PHOTOELECTRIC EYE SYSTEM IS

OBSTRUCTED. FAILURE TO MAKE

ADJUSTMENTS, IF NECESSARY,

CAN RESULT IN SEVERE OR FATAL

INJURY.

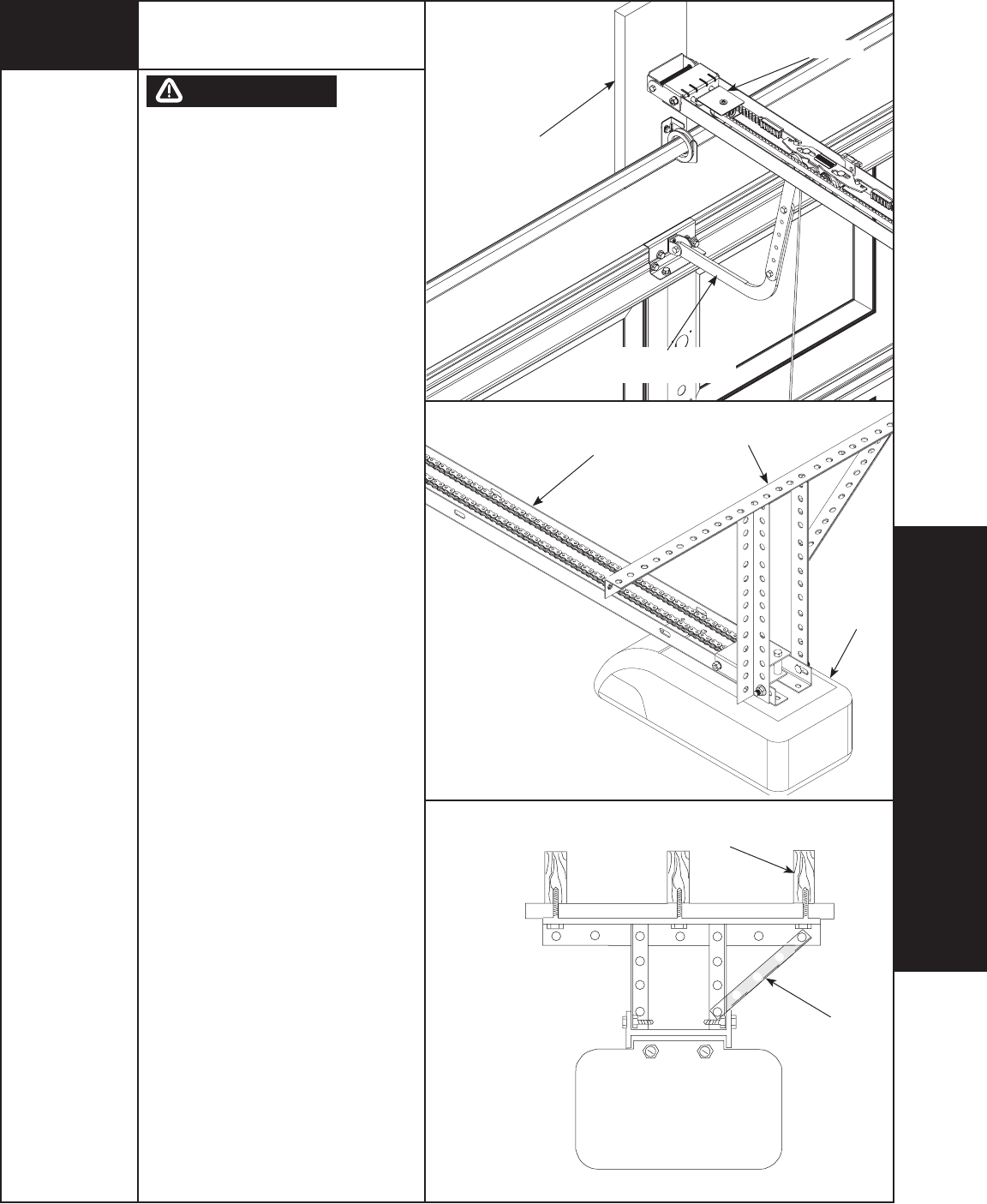

1. Install operator rail 1/2” to 1-1/2”

(13 - 38 mm) above high arc of top

section of the door.

2. Mount operator to ceiling so that

1” to 1-1/2” (25 - 38 mm)

clearance is maintained between

trolley rail and top section when

door is fully open (trolley rail will

slope down towards rear).

3. Attach door arm to operator

bracket.

4. Attach operator rail to suitable

mounting surface 2x6 lumber

minimum.

5. Attach operator to ceiling using

perforated angle.

IMPORTANT: PERFORATED ANGLES

MUST BE SECURELY ATTACHED TO

SOUND FRAMING MEMBER(S).

WARNING

Tape Measure

Power Drill

7/16” Socket

Driver

HEADER

OPERATOR RAIL

DOOR ARM TO

OPERATOR BRACKET

SUITABLE MOUNTING

SURFACE 2X6

LUMBER MINIMUM

OPERATOR

FRAMING MEMBERS

PERFORATED ANGLE

OPERATOR

RAIL

PERFORATED

ANGLE