33

Please Do Not Return This Product To The Store. Contact your local Wayne-Dalton dealer. To find your local Wayne-Dalton dealer, refer to your

local yellow pages/business listings or go to the Find a Dealer section online at www.wayne-dalton.com

Tools Needed:

Tools Needed:

�

�

OPTIONAL INSTALLATION

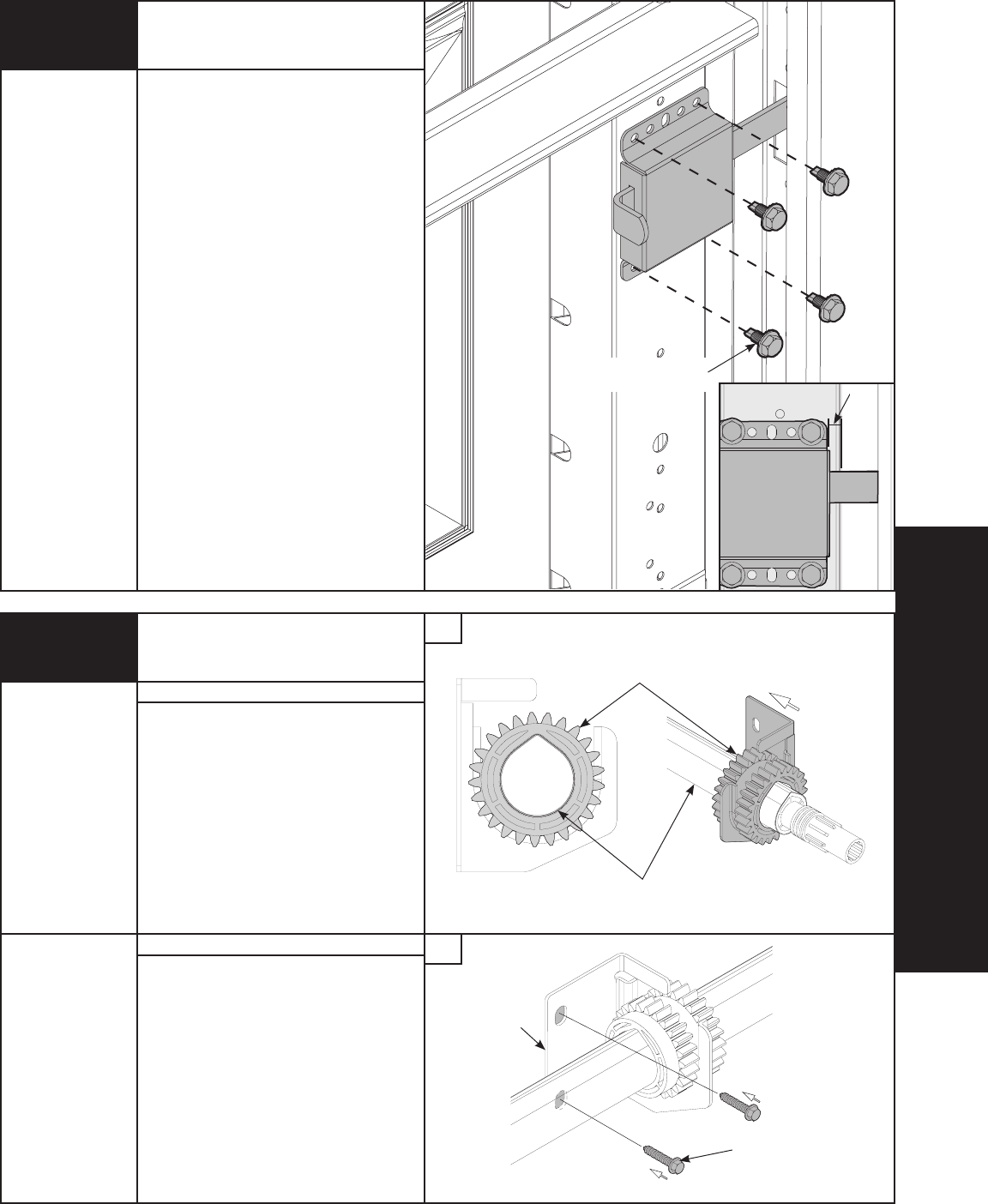

Side Lock

Install the side lock on the second

section of the door. Secure the lock to

the section with (4) 1/4”- 20 x 11/16”

self drilling screws. Square the lock

assembly with the door section and

align with the square hole in the vertical

track. The side lock should be spaced

in approximately 1/8” from the section

edge.

IMPORTANT: SIDE LOCKS MUST BE

REMOVED OR MADE INOPERATIVE IN

THE UNLOCKED POSITION IF AN

OPERATOR IS INSTALLED ON THE

DOOR.

NOTE: After completing this step,

continue with Step 13 on page 19.

(4) 1/4”- 20 X 11/16”

SELF DRILLING SCREWS

Power Drill

7/16” Socket

Driver

Tape Measure

1/8”

DoorMaster

TM

Bracket

NOTE: When installing a DoorMaster

TM

operator use the center bracket and

drive gear supplied with your operator

(located in DoorMaster

TM

package).

Slide the DoorMaster

TM

bracket/drive

gear assembly onto the TorqueMaster

®

spring tube, so that the drive gear/center

bracket assembly are in the center of

the TorqueMaster

®

spring tube.

NOTE: After completing this step,

continue with step 20 on page 23.

DOORMASTER

TM

BRACKET/ DRIVE

GEAR ASSEMBLY

TORQUEMASTER

®

TUBE

A

A

DOORMASTER

TM

BRACKET/

DRIVE GEAR ASSEMBLY

Locate the center bracket, mark the

header halfway between the flagangles

and level the TorqueMaster

®

spring

tube. Drill 1/8” pilot holes for the lag

screws. Fasten the metal bracket to the

header using (2) 1/4” x 1-1/2” hex head

lag screws.

NOTE: After completing this step,

continue with step 29 on page 29.

B

B

Tools Needed:

Power Drill

1/8” Drill Bit

7/16” Socket

Driver

Tape Measure

Level

(2) 1/4” X 1-1/2” HEX

HEAD LAG SCREWS