25

Please Do Not Return This Product To The Store. Contact your local Wayne-Dalton dealer. To find your local Wayne-Dalton dealer, refer to your

local yellow pages/business listings or go to the Find a Dealer section online at www.wayne-dalton.com

Tools Needed:

Tools Needed:

INSTALLATION

23

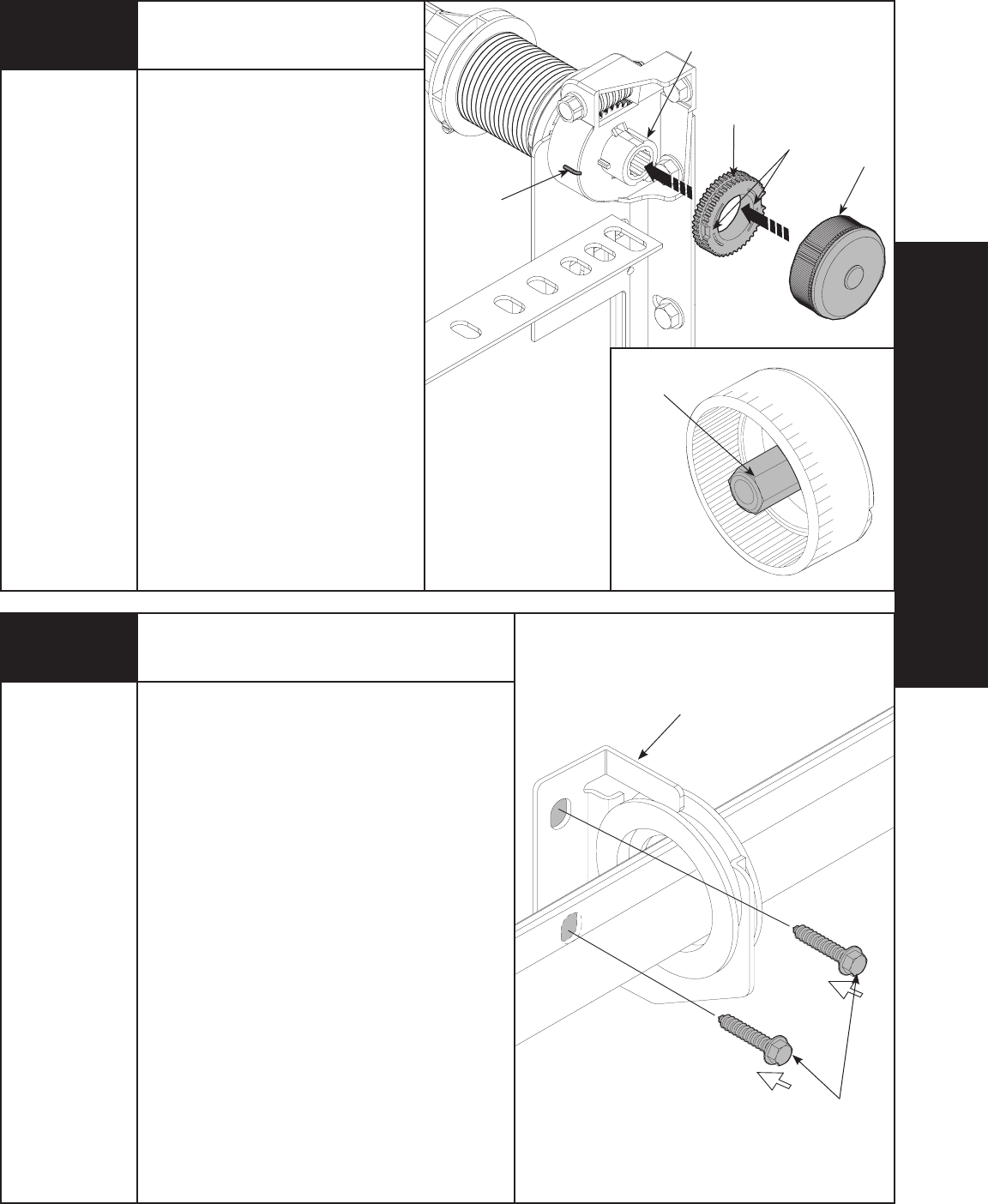

Counter Installation

Install the right side counter gear, with

the missing tooth toward the outside

and away from the end bracket. Press

the counter gear onto the end bracket

until snaps engage.

Select the right hand counter cover and

align the hex of the counter cam with

the end of the winding shaft. Also, align

the “0” on the counter cover with the

raised rib on the end bracket. Press the

counter cover against the counter gear

until it locks into place.

Repeat on left hand side for double

spring applications.

NOTE: No drive gear, counter gear or

counter cover is required on left hand

side for single spring applications. Only

an end bracket is needed.

IMPORTANT: AT THIS TIME DO NOT

WIND COUNTERBALANCE SPRINGS!

CENTER

BRACKET

ASSEMBLY

(2) 5/16” X 2” HEX

HEAD LAG SCREWS

Securing Center Bracket Bushing

24

HEX OF THE

COUNTER CAM

WINDING

SHAFT INSIDE

END BRACKET

MISSING

TOOTH

RAISED RIB

COUNTER

COVER

COUNTER

GEAR

NOTE: If you are installing an idrive

®

opener on your

garage door, skip this step and continue with Step 25.

NOTE: If you are not installing an idrive

®

opener on

your garage door, you must install the center bracket

bushing assembly. Follow these instructions for

non-idrive

®

operated garage doors.

NOTE: If you are installing a DoorMaster™ opener,

see optional DoorMaster™ Bracket installations on

page 33, Figure B.

IMPORTANT: TORQUEMASTER

®

SPRING TUBE MUST

BE LEVEL AFTER CENTER BRACKET ASSEMBLY IS

FASTENED TO HEADER.

To locate the center bracket, mark the header halfway

between the flagangles and level the TorqueMaster

®

spring tube. Drill pilot holes into header for the lag

screws. Fasten the metal bracket to the header using

(2) 5/16” X 2” hex head lag screws.

NOTE: Upon completion of this step, continue with

Step 29.

Power Drill

3/16” Drill Bit

7/16” Socket

Driver

None