Mfg No. 164771, Page 15

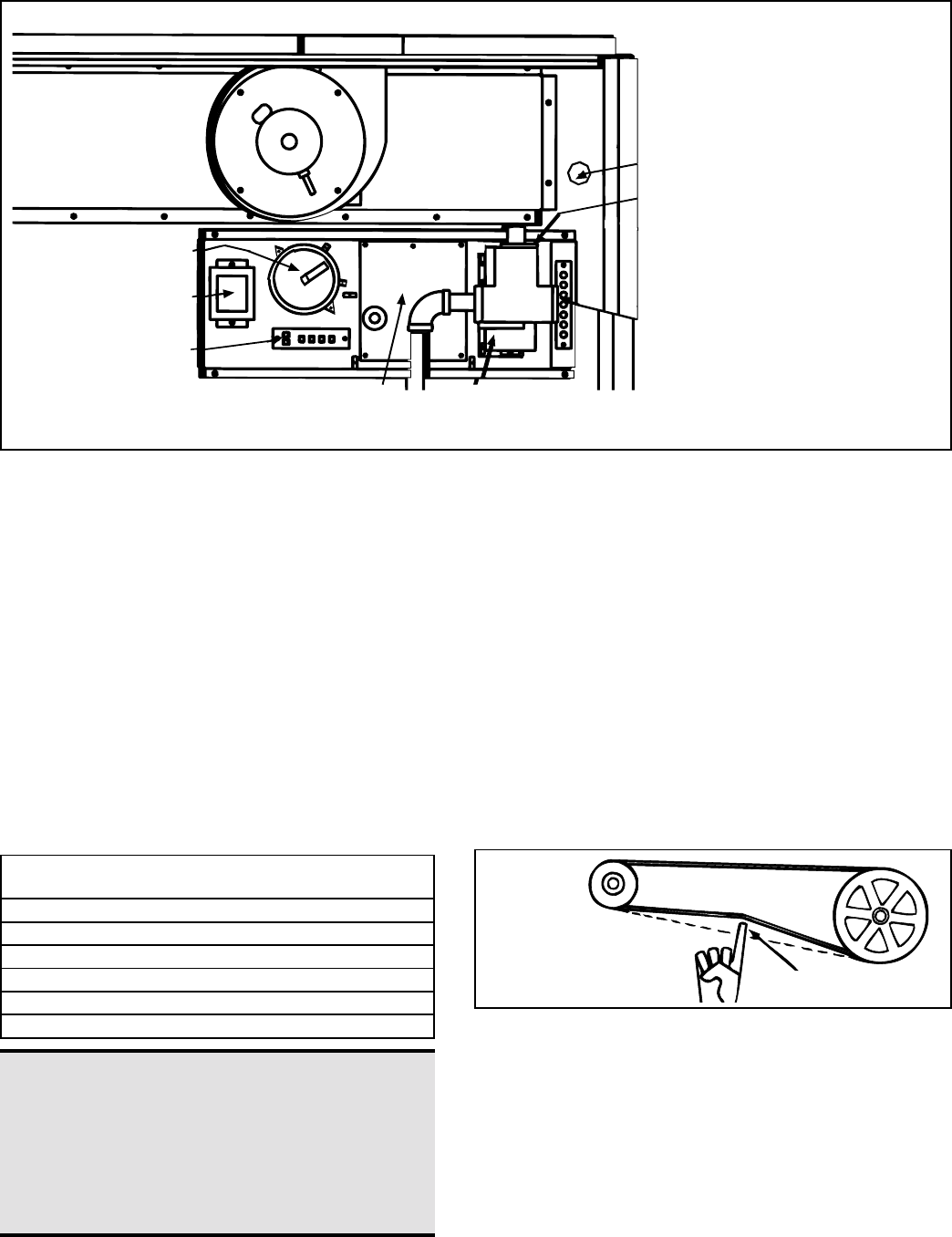

Limit Control

Supply Wiring Terminal Block

(behind the gas valve)

(Line voltage enters the control

compartment through a hole in

the top of the heater cabinet.)

Thermostat

Terminal Strip

(Thermostat wires enter

the control compartment

through a hole in the right

side of the heater cabinet.)

Contactors

Gas

Valve

Ignition Control

Module

Terminal Strip

Transformer

Pressure Switch

Venter

3/4 (19mm)

Figure 16 -

Check Belt

Tension

Figure 15 - Control

Locations

14. Blower Motor and Drive

Model CAUA units are equipped with either direct drive motor(s) and

blower(s) or adjustable belt-drive blower(s) and motor.

Direct Drive

All direct drive blower motors are 1 horsepower. Sizes 150-200 have a

single motor. Size 150 has a 12-9 blower; Size 200 has a 12-12 blower.

Sizes 250-400 have dual motors with dual 12-9 blowers.

Belt Drive

The motor horsepower on a belt drive unit is whatever was specified on

the order ranging in size from 1/4 HP to 5 HP. Check the heater rating plate

and the motor rating plate.

As part of the start-up procedure, check belt tension. Proper belt tension

is important to the long life of the belt and motor. A loose belt will cause

wear and slippage. Too much tension will cause excessive motor and blower

bearing wear. Adjust the belt tension by turning the adjusting screw on the

motor base until the belt can be depressed 3/4". (See Figure 16.) After

correct tension is achieved, re-tighten the locknut on the adjustment screw.

Be sure that the belt is aligned in the pulleys.

13. Combustion Air Proving

Switch

The combustion air proving switch is a pressure sensitive switch

that monitors air pressure to ensure that proper combustion air is

available.

The switch is single pole/double throw with the normally open

contacts closing when the proper airflow is sensed in the system.

On start-up when the heater is cold, the sensing pressure is at the

most negative level, and as the heater and flue system warm up, the

sensing pressure becomes less negative. After the system has reached

equilibrium (about 20 minutes), the sensing pressure levels off.

If a restriction or excessive flue length or turns cause the sensing

pressure to be outside the switch setpoint, the pressure switch will

function to shut off the main burners. The main burners will remain

off until the system has cooled and/or the flue system resistance is

reduced. The table below lists the approximate water column nega-

tive pressure readings and switch setpoints for sea level operating

conditions.

Model Start-Up Equilibrium Set Point Set Point

Size Cold “OFF”“ON”

150 1.45 1.05 .75 .90

200 1.50 1.05 .75 .90

250 1.55 1.10 .75 .90

300 1.60 1.15 .75 .90

350 1.30 1.05 .75 .90

400 1.20 1.00 .75 .90

DANGER: Safe operation of this unit requires

proper venting flow. NEVER bypass the com-

bustion air proving switch or attempt to operate

the unit without the venter running and the

proper flow in the vent system. Hazardous

conditions could result. See Hazard Levels, page

2.

Most blower motors are equipped with thermal overload protection of the

automatic, reset type. If the motor is not equipped with thermal overload

protection, the unit will be equipped with a starter. The adjustable setting

on the starter will be factory set to match the amp draw of the motor and

sealed. No change should be made to the starter setting unless the original

motor is replaced. Starters are equipped with a manual reset. If an overload

condition is experienced, the condition must be corrected and the starter

must be manually reset.

After the installation is complete including all ductwork, the amp draw of

the motor should be checked with an amp meter to verify that the motor

amp rating on the motor nameplate is not being exceeded. Amps may be

adjusted downward by reducing the blower speed or by increasing the duct

system static pressure. The temperature rise must be within the range

specified on the unit rating plate.