R-2397

21

Pin No. Signal I/O Description

1-3 A0-A2 IN Connected to GND.

4 VSS IN Connected to VC(-5V).

5 SDA IN/OUT Serial data input/output : input/outputs data to IC1.

6 SCL IN Clock signal input : input/outputs sireal data at every one pulse.

7 TEST IN Connected to VC(-5V).

8 VCC IN Connected to GND.

SERVICING

1. Precautions for Handling Electronic Components

This unit uses CMOS LSI in the integral part of the

circuits. When handling these parts, the following pre-

cautions should be strictly followed. CMOS LSI have

extremely high impedance at its input and output termi-

nals. For this reason, it is easily influenced by the

surrounding high voltage power source, static electricity

charge in clothes, etc, and sometimes it is not fully

protected by the built-in protection circuit.

In order to protect CMOS LSI.

1) When storing and transporting, thoroughly wrap them in

aluminium foil. Also wrap all PW boards containing them

in aluminium foil.

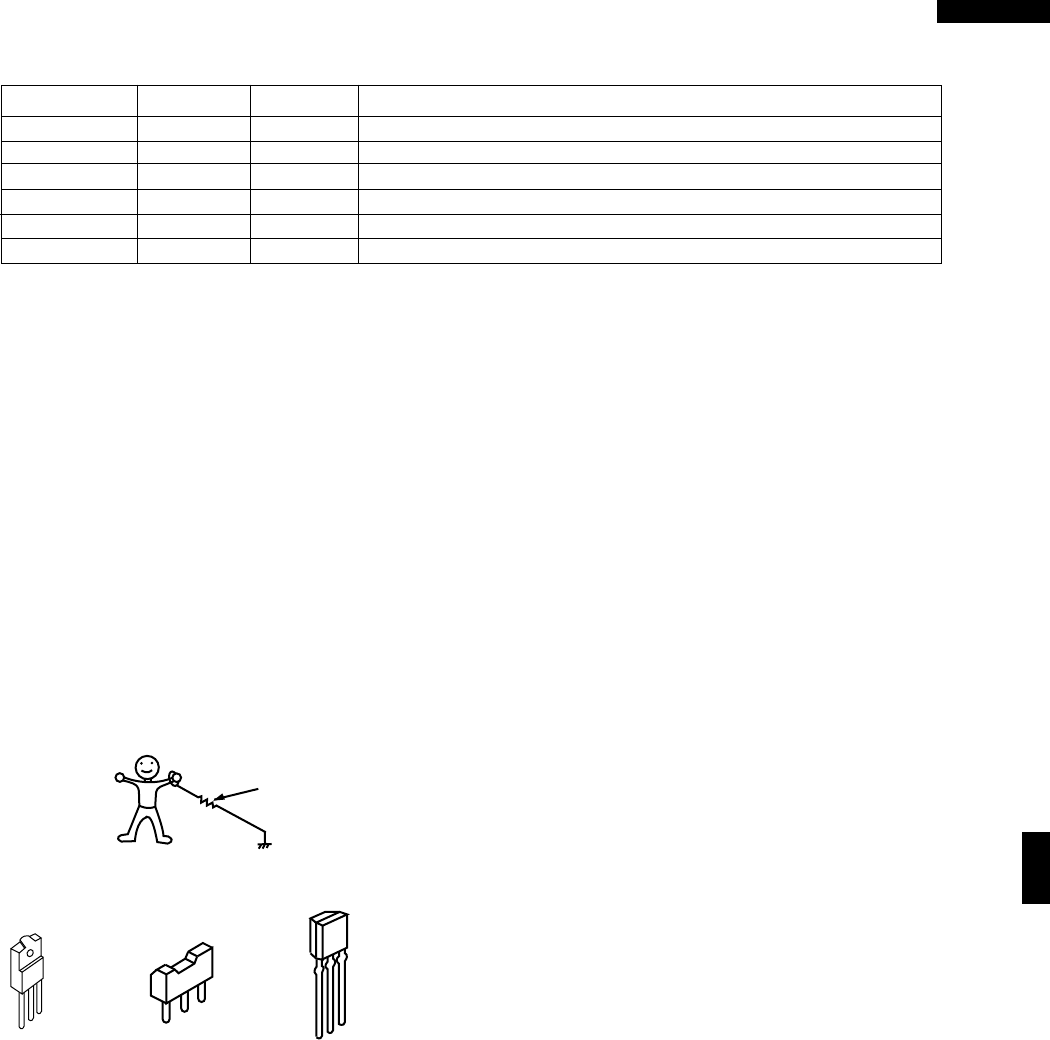

2) When soldering, ground the technician as shown in the

figure and use grounded soldering iron and work table.

approx. 1M ohm

2. Shapes of Electronic Components

E

C

B

Tit

E

C

B

E

C

B

3. Servicing of Touch Control Panel

We describe the procedures to permit servicing of the

touch control panel of the microwave oven and the

precautions you must take when doing so. To perform

the servicing, power to the touch control panel is avail-

able either from the power line of the oven itself or from

an external power source.

(1) Servicing the touch control panel with power supply

of the oven:

CAUTION: THE HIGH VOLTAGE TRANSFORMER OF

THE MICROWAVE OVEN IS STILL LIVE

DURING SERVICING PRESENTS A HAZ-

ARD.

Therefore, when checking the performance of the touch

control panel, put the outer cabinet on the oven to avoid

touching the high voltage transformer, or unplug the

primary terminal (connector) of the high voltage trans-

former to turn it off; the end of such connector must be

insulated with an insulating tape. After servicing, be

sure to replace the leads to their original locations.

A. On some models, the power supply cord between the

touch control panel and the oven itself is so short that the

two can’t be separated. For those models, check and

repair all the controls (sensor-related ones included) of

the touch control panel while keeping it connected to the

oven.

B. On some models, the power supply cord between the

touch control panel and the oven proper is long enough

that they may be separated from each other. For those

models, therefore, it is possible to check and repair the

controls of the touch control panel while keeping it apart

from the oven proper; in this case you must short both

ends of the door sensing switch (on PWB) of the touch

control panel with a jumper, which brings about an

operational state that is equivalent to the oven door

being closed. As for the sensor-related controls of the

touch control panel, checking them is possible if dummy

resistor(s) with resistance equal to that of the controls

are used.

(2)Servicing the touch control panel with power supply from

an external power source:

Disconnect the touch control panel completely from the

oven proper, and short both ends of the door sensing

switch (on PWB) of the touch control panel, which brings

about an operational state that is equivalent to the oven

door being closed. Connect an external power source to

the power input terminal of the touch control panel, then

it is possible to check and repair the controls of the touch

control panel it is also possible to check the sensor-

related controls of the touch control panel by using the

dummy resistor(s).

4. Servicing Tools

Tools required to service the touch control panel assem-

bly.

1) Soldering iron: 30W

(It is recommended to use a soldering iron with a

grounding terminal.)

2) Oscilloscope: Single beam, frequency range: DC-10MHz

type or more advanced model.

3) Others: Hand tools

5. Other Precautions

1) Before turning on the power source of the control unit,

remove the aluminium foil applied for preventing static

electricity.

2) Connect the connector of the key unit to the control unit

being sure that the lead wires are not twisted.

3) After aluminium foil is removed, be careful that abnormal

voltage due to static electricity etc. is not applied to the

input or output terminals.

4) Attach connectors, electrolytic capacitors, etc. to PWB,

making sure that all connections are tight.

5) Be sure to use specified components where high preci-

sion is required.

Transistor

DTA114YS

DTB143ES

DTD143ES

KRA101M

Transistor

2SA1561

2SB1238

Transistor

2SB953