SMC sierra monitor corporation Sentry Instruction Manual - Version 6

SERVICE

Page: 76

7.8 HYDROGEN SULFIDE MODULE (5100-05)

7.8.1 DESCRIPTION

Model 5100-05 Hydrogen Sulfide Sensor Module

includes a sensor assembly and electronic

assembly installed in an explosion proof housing.

The sensor assembly includes a reuseable housing

and disposable electrochemical sensor. The

assembly screws into one hub of the sensor

module enclosure and plugs into the bottom

electronics card via a six pin connector.

Cabling from the controller connects to a three pin

spring loaded terminal strip on the electronics

assembly.

7.8.2 TROUBLE ANALYSIS

Electrical adjustment, or replacement of the sensor

will be necessary under the following conditions:

• Controller displays the following error

messages

SENSOR FAILURE

LOW SENSITIVITY

• False readings or alarms are received

due to sensor inaccuracy.

Warning: During sensor adjustments the

concentration reading on the controller will be inaccurate

and alarm level concentrations may be displayed. If false

activation of the alarm relays will cause a problem

disconnect the relay wiring prior to adjustment or turn the

module off using the "Change Module" mode.

NOTE

Although all the necessary data can be collected with a

voltmeter at the sensor module, some helpful

information can be displayed on the controller or

printed. See diagnostic codes 0004 and 0008 in

Appendix C.

7.8.3 ADJUSTMENT PROCEDURE

Prior to reading voltages and making adjustments perform

a visual inspection to confirm that there are no physical

problems such as water in the electronics enclosure,

wiring damage or corrosion.

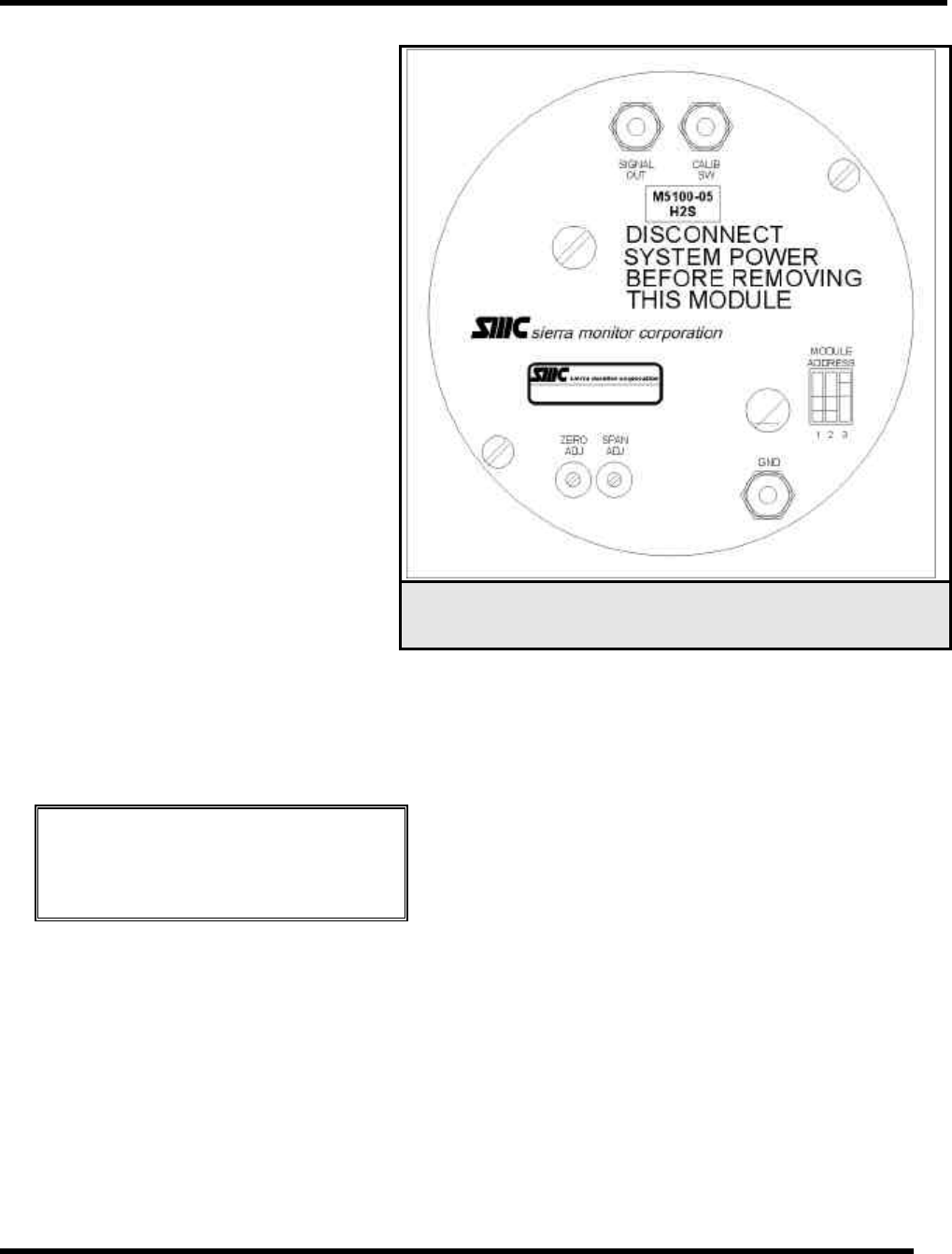

Use Figure 7-9 to locate test points during the following

procedures.

7.8.3.1 SIGNAL ADJUSTMENT

It is unlikely that any electrical adjustment will be

required except when a new sensor is installed.

To make the electrical adjustment connect a voltmeter to

SIGNAL OUT (pos) and GND (ground) and use SPAN ADJ

potentiometer to adjust the voltage based on the

following:

• 1 ppm H

2

S = 0.02 VDC.

• 100 ppm H

2

S = 2.00 VDC.

7.8.3.2 SENSOR REPLACEMENT

The Hydrogen Sulfide sensor should be replaced when it

can no longer be calibrated correctly. Generally this is

every twenty four to thirty months.

The SENSOR FAILURE message for Hydrogen Sulfide

sensors does not indicate a specific failure of the sensor

but indicates that the sensor is not correctly connected to

the electronics. If this message appears check that the

sensor harness is correctly installed to the connector on

the bottom electronics board.

The gas sensor which is located inside the sensor

assembly housing can be replaced without replacement of

the housing. To replace the sensor:

Figure 7-9

Cover Plate - Hydrogen Sulfide Module