SMC sierra monitor corporation Sentry Instruction Manual - Version 6

INSTALLATION

Page: 17

3. INSTALLATION

NOTE

All systems are factory are pre-configured and calibrated.

All sensors are tagged to indicate the controller (alpha)

and the sensor module number (1 - 8).

Identify all components of the system during unpacking

and install using the factory configuration.

The system will power up in a calibrated and fully

functional condition.

3.1 CONTROLLER LOCATION

Rack mounted controllers should be installed in a control

room environment where they will be relatively free from

dust and temperature extremes. For ease of operation

select a rack window space at approximately eye level.

Four controllers can be installed side by side in a 19"

instrument shelf.

Enclosed controllers for outdoor applications should be

located in the most protected location available with

consideration for easy access for installation and

calibration. The enclosures should be mounted on a

vertical surface with the key board at approximately eye

level. The enclosure should not face directly into the sun.

3.2 SENSOR MODULE LOCATIONS

Select locations for each of the sensor modules based on

the following:

• Consider the density, relative to dry air, of the gas to

determine height of module above floor or ground

level:

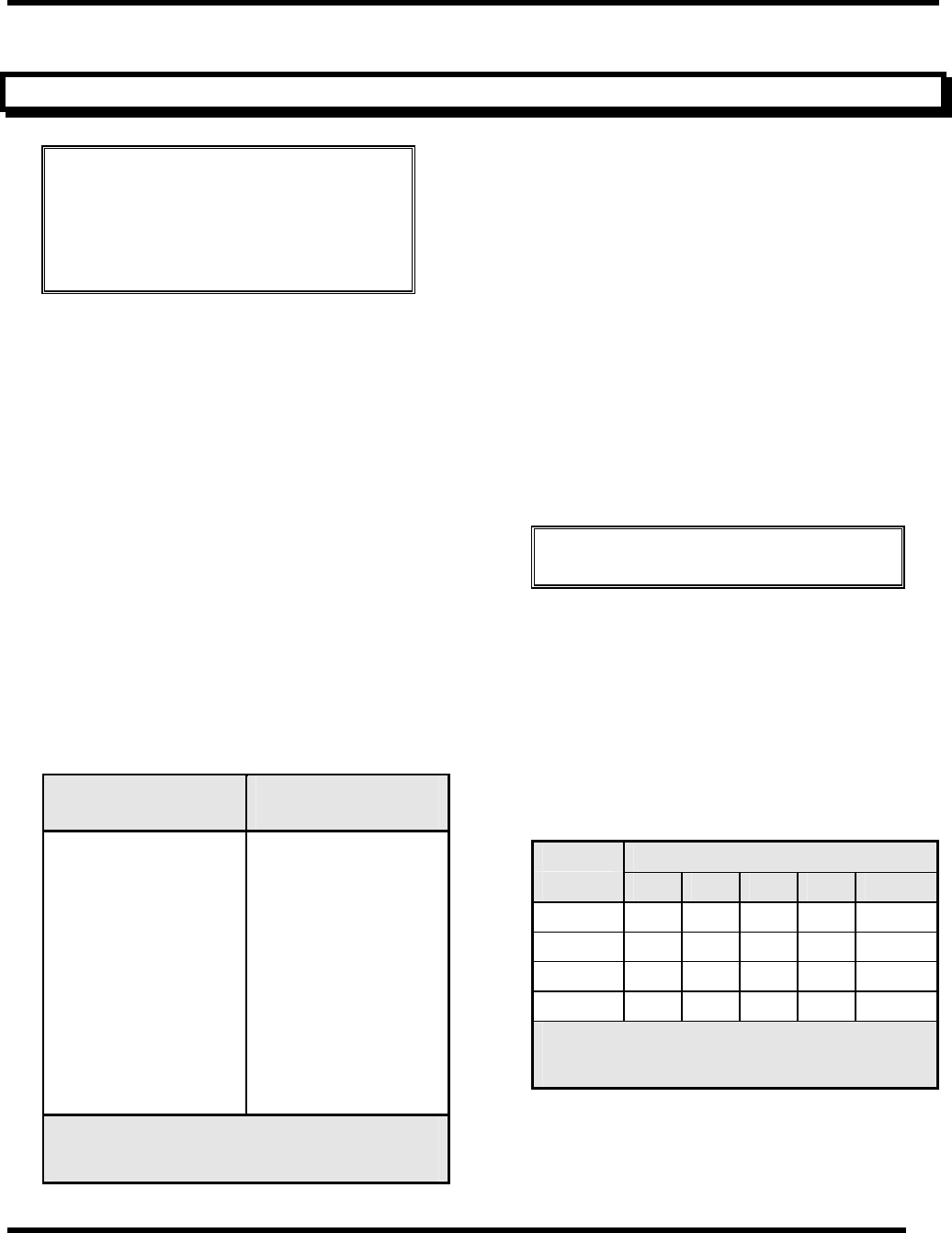

Gas Density

(Air = 1.00)

Air 1.00

Ammonia 0.60

Carbon Monoxide 0.97

Chlorine 2.49

Ethylene Oxide 1.52

Hydrogen 0.07

Hydrogen Chloride 1.27

Hydrogen Cyanide 0.94

Hydrogen Sulfide 1.19

Methane 0.55

Nitrogen Dioxide 1.58

Oxygen (Air) 1.10

Sulfur Dioxide 2.26

Table 3-1

Specific Gravity of Selected Gases

• Modules should be placed close to the potential source

of gas.

• Modules should be placed in areas accessible for

calibration.

• Sensors should be pointed down and the conduit

should include an inverse trap to reduce moisture

(condensation) from accumulating in the electronics

enclosure Figure 3-3.

3.3 WIRING

Plan the wiring arrangement to minimize installation

expense but with redundancy for critical locations. Wire

shall be Belden (or equivalent) 949X (where X = 2, 3, 4, or

5 depending on wire gauge). If high RFI or EMI levels

exist wiring should be protected by conduit or shield.

Shielded wire shall be Belden (or equivalent) 936X.

NOTE

In no case should the drain wire of shielded cable be used

as one of the conductors.

• Any modules which are located in a common

geographical area a long distance from the controller

can be connected to the same three conductor wire run

installed from the controller to that area. Table 3-2,

Figure 3-4.

• The remote auxiliary power supply option can be used

for installation of one or more modules a long distance

from the controller location. The connection from the

controller to the remote power supply is via a two

conductor "data link" Figure 3-4.

Number of Maximum length of wire run (feet)

modules 500 1,000 2,000 3,000 5,000

1

20 20 18 16 14

2

20 18 14 12 xx

3

18 16 12 xx xx

4

16 14 12 xx xx

Table 3-2

Minimum Wire Gauges