39

87%-Efficiency Boilers –

Special Instructions

Water Piping

An 87%-efficiency boiler requires a minimum inlet

water temperature of 120ºF (49ºC) to prevent exces-

sive condensation in the combustion chamber. An

87%-efficiency boiler operated with an inlet tempera-

ture of less than 120ºF (49ºC) must have a manual

bypass or an approved low-temperature operation

system to prevent problems with condensation. A man-

ual bypass, shown in Fig. 15, must be piped into the

system at the time of installation. This piping is like a

primary/secondary boiler installation with a bypass in

the secondary boiler piping. Raypak strongly recomm-

NOTE: The constructions of the 84%- (standard)

and 87%-efficiency (optional) boilers are very similar,

and they are installed to the same requirements,

except as noted in this section.

ends that a thermometer be placed into the boiler inlet

piping next to the in/out header to facilitate tempera-

ture adjustment. Inlet water temperatures below 120ºF

(49ºC) can excessively cool the products of combus-

tion, resulting in condensation on the heat exchanger.

Venting

Appliance Categories

See Table Q for appliance category requirements for

the 87%-efficiency Hi Delta.

CAUTION: Proper installation of flue venting is criti-

cal for the safe and efficient operation of the boiler.

NOTE: For additional information on appliance cat-

egorization, see appropriate code NFGC (U.S.) and

B149.1 (Canada), or applicable local building codes.

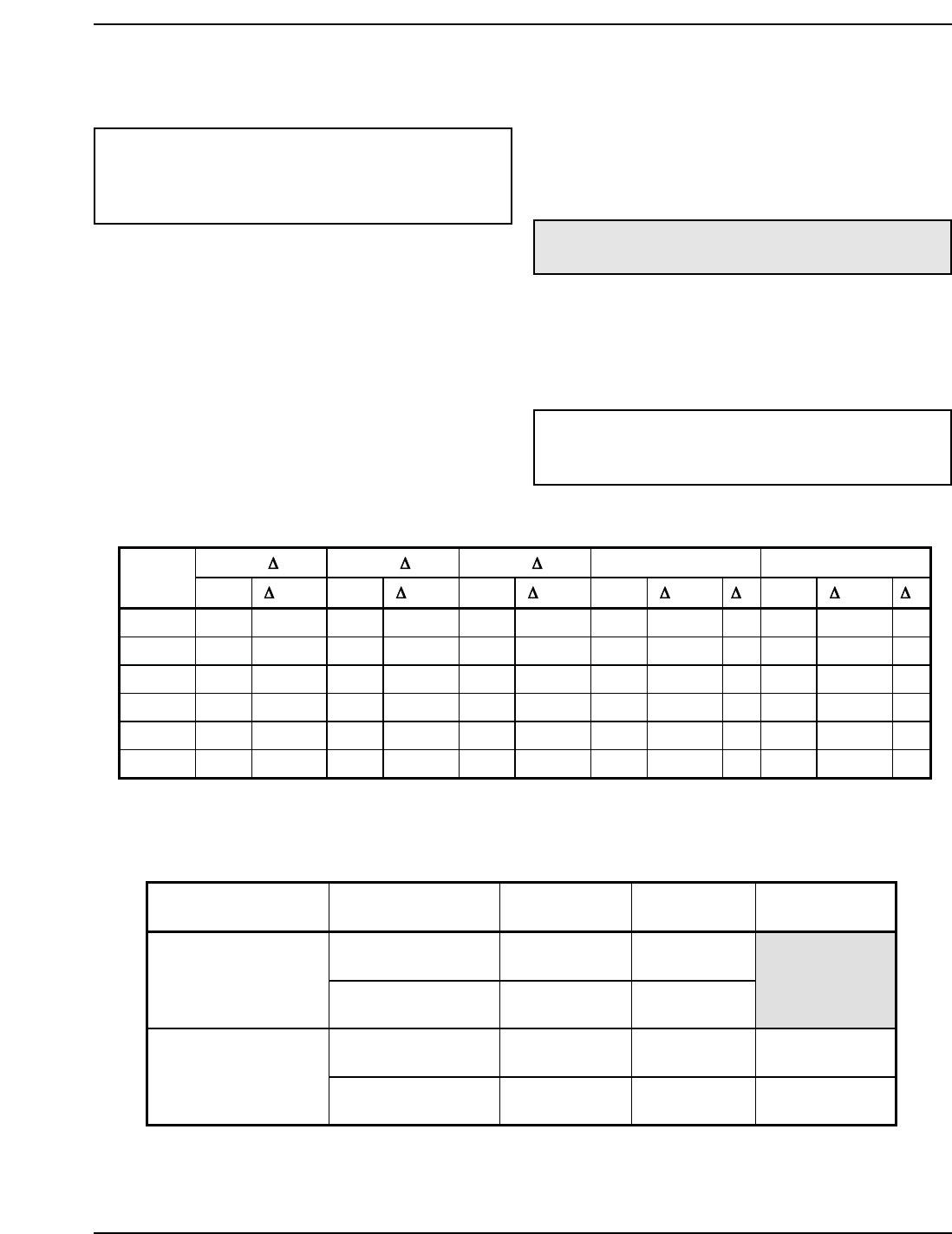

10°F T 20°F T 30°F T Min. Flow Max Flow

Model

No.

gpm

P (ft) gpm P (ft) gpm P (ft) gpm P (ft) Tgpm P (ft) T

302AE 52 3.3 26 <1.0 N/A N/A 20 <1.0 26 90 9.8 6

402AE 69 6.0 35 1.5 23 <1.0 20 <1.0 35 90 10.0 8

502AE 87 9.7 44 2.5 29 1.1 22 <1.0 40 90 10.4 10

652AE N/A N/A 57 4.4 38 2.0 28 1.1 40 90 10.8 13

752AE N/A N/A 65 6.1 44 2.8 33 1.6 40 90 11.3 15

902AE N/A N/A 78 8.9 52 4.1 39 2.3 40 90 11.7 17

Combustion

Air Supply

Exhaust

Configuration

Heater Venting

Category

Certified

Materials

Combustion Air

Inlet Material

Vertical Natural Draft

Venting

II

Stainless Steel

(Gas Tight)

From Inside Building

(Non-Direct Venting)

Horizontal Through-

the-Wall Venting

IV AL29-4C

Vertical Natural Draft

Venting

II

Stainless Steel

(Gas Tight)

Galvanized Steel

PVC

From Outside Building

(Direct Venting)

Horizontal Through-

the-Wall Venting

IV AL29-4C

ABS

CPVC

Table P: Heater Rate of Flow and Pressure Drop

Table Q: Category Determination for Venting Purpose and Venting Arrangement

Note: Basis for minimum flow is 20 gpm or 40°F ΔT. Basis for maximum flow is 90 gpm.