35

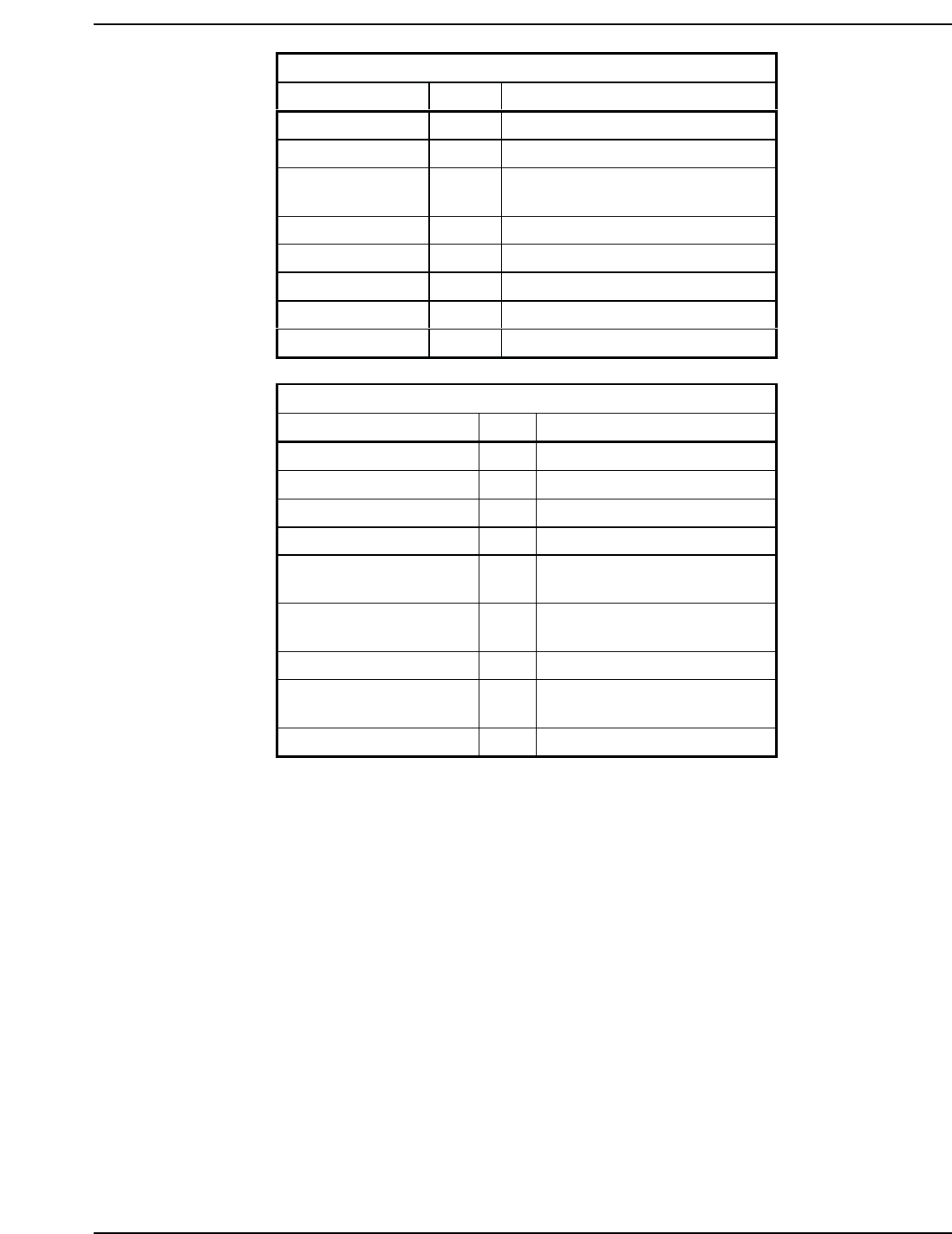

External Lights

Light Color Indication

Power Blue Main power is on

Call For Heat Yellow Thermostat is closed

Safety Red

One or more safeties is inopera-

tive

Ignition Red Ignition module is inoperative

Flow Green Flow is present

Blower 1 Green Blower 1 is on

Stage 1 Green Stage 1 is on

Stage 2 Green Stage 2 is on

Internal Lights

Light Color Indication

Board Power Yellow Board power is on

Low Water Cut-Off Red Low water cut-off is open

Blocked Vent Red Vent is blocked

Manual Reset Hi-Limit Red Manual reset is open

Low Gas Pressure

Switch

Red Low gas pressure

High Gas Pressure

Switch

Red High gas pressure

(Not Used) Red

PVC Vent Limit Red

Vent temperature exceeds

limits

Auto Reset High Limit Red Auto reset option

Table N: LED Indicators

24. Upon sufficient flow from the heater pump, the

flow switch contacts will close.

25. The flow light is energized; located on the diag-

nostics panel.

26. A 24 VAC signal is also sent to the “TH” terminal

located on the ignition module.

27. Once the 24 VAC “TH” signal is received at the

ignition module, a 120 VAC signal is sent from F2

on the ignition module to the 120 VAC pilot duty

terminals, located at J-14 on the circuit board.

28. The 120 VAC signal continues to the coil of the

blower relay K-3 (N.O.).

29. The 120 VAC signal continues to the 120 VAC

safety terminals located at J-13 on the circuit

board.

30. When the coil on relay K-3 (N.O.) is powered, the

relay contacts (K-3) close and energizes the blow-

er from the J-8 connections on the CPW board.

31. After proper air pressure is received in the air

plenum, the air pressure switch will close.

32. A 24 VAC signal is now sent to the blower LED on

the diagnostics board.

33. Power is applied to the optional equipment inter-

lock connection (normally jumpered).

34. The 24 VAC signal is then sent to the 24 VAC safe-

ty connector.

35. 24 VAC is now sent to the pressure switch (P.S.)

terminal on the ignition module.