28

5. Remove the screws, retaining ring and rain gasket

from top of heater.

6. Remove the screws, flue collar and gasket from

the run side of the tee located in the flue box on

top of the heater.

7. Reverse the components and reattach in the new

location.

8. Make sure that the stainless steel cover, now lo-

cated on the run side of the tee, is sealed to avoid

any flue gas spillage.

Venting Installation Tips

Support piping:

• horizontal runs - at least every 5 ft

• vertical runs - use braces

• under or near elbows

Venting Configurations

For heaters connected to gas vents or chimneys, vent

installations shall be in accordance with the NFGC

(U.S.), or B149.1 (Canada), or applicable provisions of

local building codes.

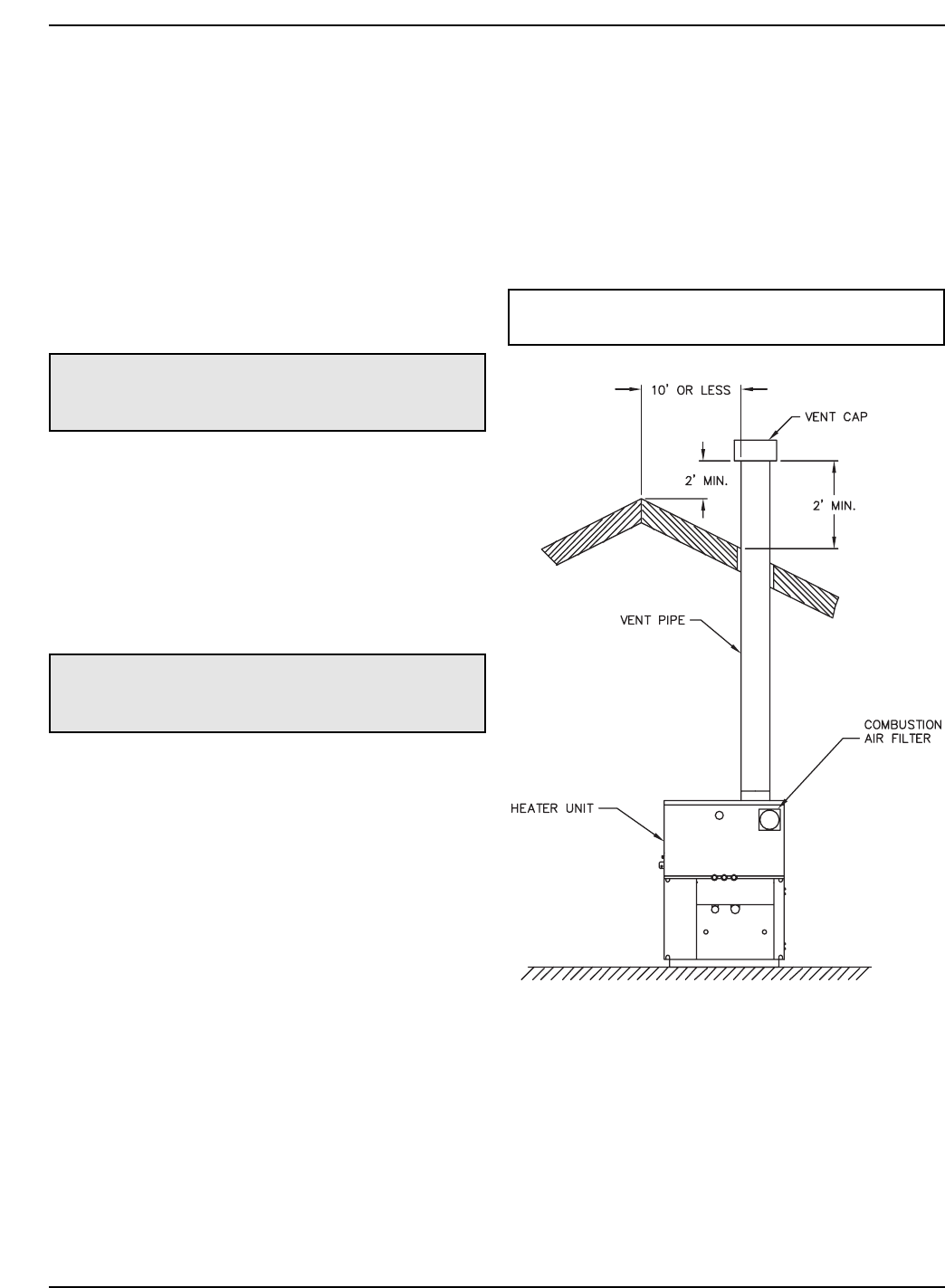

Natural Draft Vertical Venting

(Category I)

Installation

Natural draft venting uses the natural buoyancy of the

heated flue products to create a thermal driving head

that expels the exhaust gases from the flue. The nega-

tive draft must be within the range of -.01 to -.08 in.

WC as measured 12 in. above the appliance flue out-

let to ensure proper operation. Vent material must be

listed by a nationally recognized test agency.

CAUTION: The silicone vent gaskets must be prop-

erly reinstalled to prevent flue gas leakage. Replace

any torn or worn vent gaskets.

WARNING: Examine the venting system at least

once a year. Check all joints and vent pipe connec-

tions for tightness, corrosion or deterioration.

The maximum and minimum venting length for Cate-

gory I appliances shall be determined per the NFGC

(U.S.) or B149.1 (Canada).

The diameter of vent flue pipe should be sized accord-

ing to the NFGC (U.S.) and B149.1 (Canada). The

minimum flue pipe diameter for conventional negative

draft venting using double-wall Type B vent is: 5 in. for

Model 302A, 6 in. for Models 402A and 502A, and 8 in.

for Models 652A, 752A and 902A.

The connection from the appliance vent to the stack

must be as direct as possible and shall be the same di-

ameter as, or larger than, the vent outlet. The horizon-

tal breaching of a vent must have an upward slope of

not less than 1/4 inch per linear foot from the heater to

the vent terminal. The horizontal portions of the vent

shall also be supported for the design and weight of

the material employed to maintain clearances and to

prevent physical damage or separation of joints.

NOTE: A vent adapter (field-supplied) must be used

to connect Type B vent to the unit.

Fig. 24: Natural Draft Vertical Venting

(Category I)