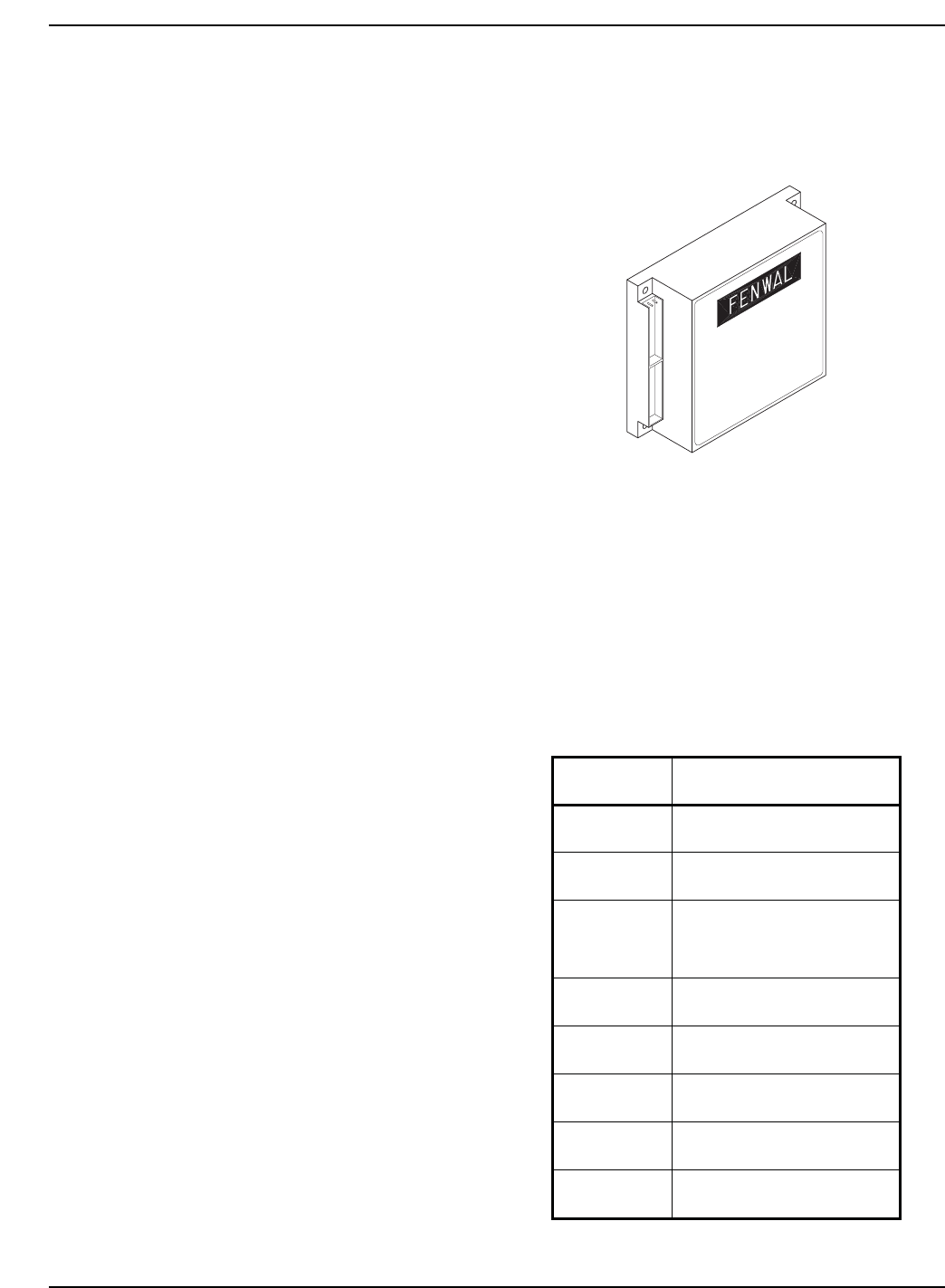

Ignition Module

When additional heat is needed, the combustion air

blower starts to purge air from the combustion cham-

ber for about 15 seconds. On proof-of-air flow, the air-

proving switch closes and the igniter is energized. To

ensure safe operation, the gas valve cannot open until

the igniter is verified. The main burner is automatically

lit when the device is powered and pre-purged. The

heater performs its own safety check and opens the

main valve only after the igniter is proven to be capa-

ble of ignition.

The standard ignition module will attempt to light three

times before locking out. To reset it, turn off power to

the heater, wait 30 seconds and re-apply power.

Code Condition

On

System OK;

No faults present

Off

Possible control fault;

Check power

1 Flash

Low air pressure, brief flash-

ing normal on start-up

2 Flashes

Flame in combustion

chamber; No call for heat

3 Flashes Ignition lockout

4 Flashes Low igniter current

5 Flashes

Low 24VAC, check control

supply voltage

6 Flashes

Internal fault;

Replace control

Fig. 29: Ignition Module

Table O: Ignition Module

Diagnostic LED Codes

36

36. Once the pressure switch signal is received at the

ignition module the hot surface igniter is energized

by a 120 VAC signal from S-1 on the ignition mod-

ule. (The hot surface igniter must draw greater

than 3.1 amps while being energized or ignition

lockout will occur after three tries.)

37. Once the ignition module determines that the hot

surface igniter amp draw is within specs and oper-

ating properly, a 24 VAC signal is output from pin

GV on the module.

38. 24 VAC signal is received to gas valve 1 thus ener-

gizing it.

39. The stage 1 LED on the diagnostics display board

is now illuminated.

40. The coil of relay K-2 (N.O.) is now energized with

the (K-2) contacts closing downstream of the

stage 2 connections.

41. The gas coming through the burners should ignite

from the heat of the hot surface igniter and the

flame should carry over from one burner to the

other burners of stage 1. The remote sensor is

now trying to sense the flame. If the flame is not

sensed within 4 seconds, the ignition module will

shut down the gas valve and retry the hot surface

igniter. During ignition retry the heater must per-

form a 15-second pre-purge and an approximate-

ly 30-second igniter warm-up before opening gas

valve 1 again. The standard ignition module will

attempt ignition a maximum of three times prior to

ignition lockout.

42. (Models 302A-402A only) 24 VAC is now waiting

at pin 3 of the stage 2 connection on the CPW

board.

43. (Models 502A-902A only) After gas valve 1 opens

and flame rectification is received, time delay relay

1 (TD-1) starts a 5-second countdown.

44. (Models 502A-902A only) After the 5 second

countdown from TD-1, 24 VAC is waiting at pin 3

of the stage 2 connection on the CPW board.

45. After closure of the stage 2 contacts Gas valve 2

in energized.

46. The stage 2 LED on the diagnostics display board

is now illuminated.

47. The heater is now operating at full fire.