7.0 Site Requirements

14

© Baxi Heating UK Ltd 2007

7.1 Location

1. The boiler may be fitted to any suitable wall with the

flue passing through an outside wall or roof and discharging

to atmosphere in a position permitting satisfactory removal

of combustion products and providing an adequate air

supply. The boiler should be fitted within the building

unless otherwise protected by a suitable enclosure i.e.

garage or outhouse. (The boiler may be fitted inside a

cupboard-see Section 7.3).

2. If the boiler is sited in an unheated enclosure then it is

recommended to leave the ON/OFF Selector Switch in

the domestic hot water and central heating position to

give frost protection.

3. If the boiler is fitted in a room containing a bath or

shower reference must be made to the relevant

requirements.

In GB this is the current I.E.E. Wiring Regulations and

Building Regulations.

In IE reference should be made to the current edition of

I.S. 813 “Domestic Gas Installations” and the current ETCI

rules.

4. If the boiler is to be fitted into a building of timber frame

construction then reference must be made to the current

edition of Institute of Gas Engineers Publication IGE/UP/7

(Gas Installations in Timber Framed Housing).

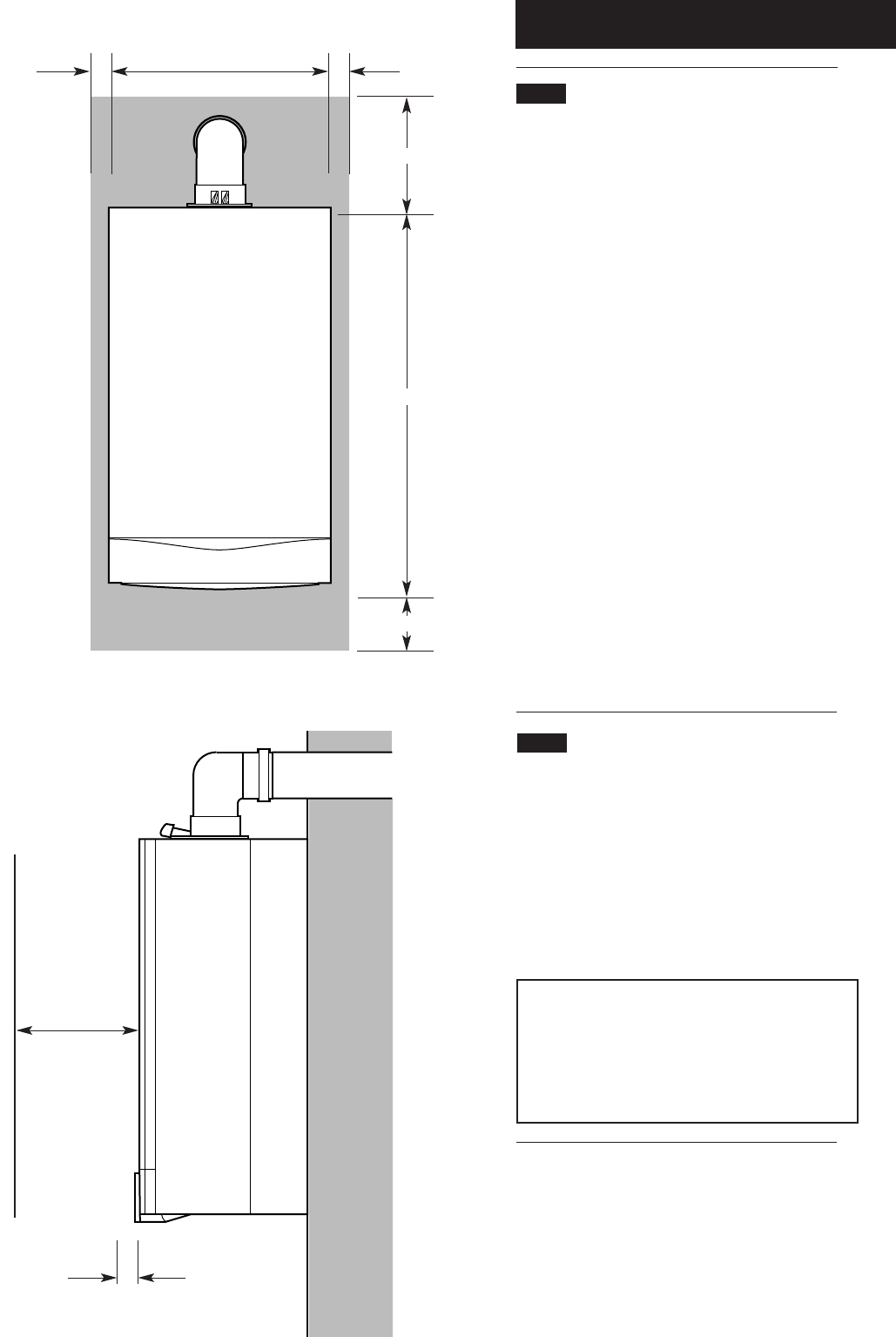

7.2 Clearances (Figs. 8 & 9)

1. A flat vertical area is required for the installation of the

boiler.

2. These dimensions include the necessary clearances

around the boiler for case removal, access during routine

maintenance and air movement. Additional clearances may

be required for the passage of pipes around local

obstructions such as joists running parallel to the front face

of the boiler.

* NOTE: The boiler can be operated with a clearance

of 5mm at the right. This is also sufficient for routine

maintenance. However a clearance of 20mm is

required if it is necessary to remove the secondary

heat exchanger. This should be considered when

siting the appliance and in the event of any

subsequent alteration in the area of installation.

200mm Min

780mm

450mm

200mm Min

20mm/5mm Min

See * NOTE:

5mm Min

5mm Min

450mm Min

For Servicing

Purposes

Fig. 8

Fig. 9

In Operation