49

Check for gas leaks

Before starting the boiler, and during initial

operation, smell near the floor and around

the boiler for gas odorant or any unusual

odor. Remove the front access panel and

smell the interior of the boiler enclosure. Do

not proceed with startup if there is any

indication of a gas leak. Use an approved

leak detection solution. Repair any leaks at

once.

ƽ WARNING

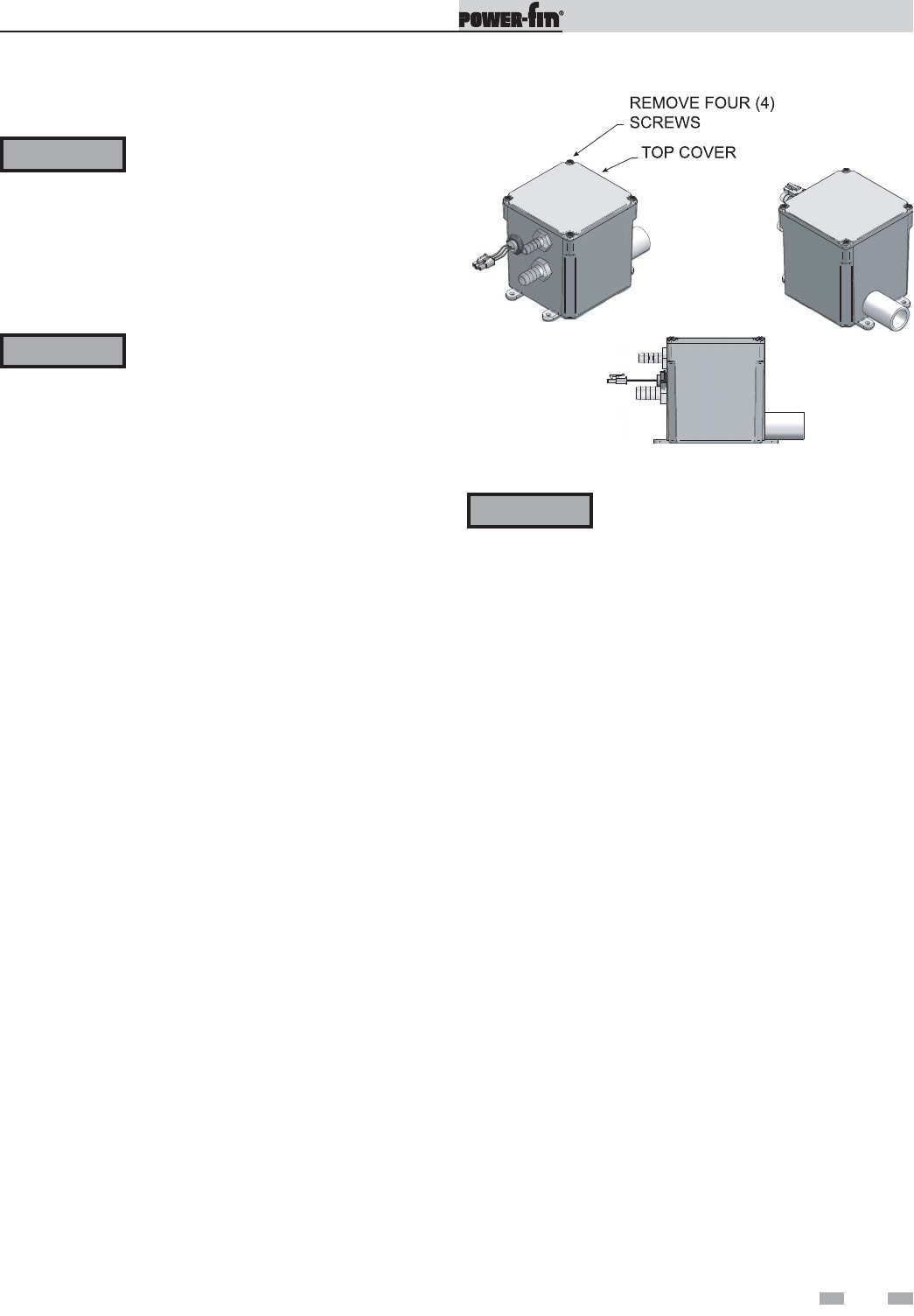

Figure 7-1_Condensate Trap

Propane boilers only – Your propane

supplier mixes an odorant with the propane

to make its presence detectable. In some

instances, the odorant can fade, and the gas

may no longer have an odor. Before startup

(and periodically thereafter), have the

propane supplier verify the correct odorant

level in the gas.

ƽ WARNING

Inspect/fill condensate system

Inspect/check condensate lines and fittings

1. Inspect the condensate drain line, condensate PVC fittings

and condensate trap.

Fill condensate trap with water

1. Remove the four (4) screws securing the top cover to the

condensate trap and remove the cover (FIG. 7-1).

2. Locate the plastic ball inside the float tube. Verify there is

nothing under the ball causing it to not seat properly.

3. Fill with fresh water until the water begins to pour out of the

drain.

4. Replace the cover.

5. Replace the four (4) screws removed in Step 1.

The condensate trap (FIG. 7-1) must be

filled with water during all times of boiler

operation to avoid flue gas emission from the

condensate drain line. Failure to fill the trap

could result in severe personal injury or

death.

ƽ WARNING

Check thermostat circuit(s)

1. Disconnect the two external wires connected to the enable

terminals on the connection board.

2. Connect a voltmeter across these two incoming wires. Close

each thermostat, zone valve, and relay in the external circuit

one at a time and check the voltmeter reading across the

incoming wires.

3. There should NEVER be a voltage reading.

4. If a voltage does occur under any condition, check and

correct the external wiring. (This is a common problem

when using 3-wire zone valves.)

5. Once the external thermostat circuit wiring is checked and

corrected if necessary, reconnect the external thermostat

circuit wires to the connection board. Allow the boiler to

cycle.

7 Start-up (continued)

Check vent and air piping

1. Inspect vent piping and air piping for signs of

deterioration from corrosion, physical damage or

sagging. Verify air piping and vent piping are intact

and correctly installed per this manual.

Placing the boiler in operation

Boiler operational checks

2. Turn the boiler main power switch to the “ON”

position.

3. Verify operation of the SMART SYSTEM control

module and Operator Interface.

4. Program the adjustable points from the Operator

Interface.

5. Push the reset for the low water cutoff (if equipped).

6. Ensure that maximum flow to the boiler does not exceed

75 GPM on Models 502 - 1302 and 90 GPM on Models

1501- 2001. Verify by checking temperature rise while

burner is firing at 100% of rated input.

7. Install a manometer on the gas supply to the boiler and

verify minimum gas supply pressure as the burner fires at

100% of rated input.

8. Verify operation of safeties as necessary (low water

cutoff, high limit, gas pressure, etc.,).

9. Verify that all adjustable points in the Operator

Interface are set as required.

Installation & Operation Manual