5 Electrical connections

Boiler operating control module

The operating temperature control for the appliance is the

SMART SYSTEM control module. It is located on the inside of

the control panel, behind the front access door. Access to adjust

the temperature set point and other user adjustable points is

made through the Operator Interface located on the right front

access door. The outlet sensor is placed in a bulbwell installed

in the outlet side of the heat exchanger top header. The inlet

sensor is located in a bulbwell on the inlet side of the heat

exchanger top header.

The operating sensor, inlet or outlet, is selectable from the

screen in the Operator Interface.

The exact temperature set point is based on your system’s

requirements. Set the control set point(s) to the desired

operating water temperature.

The maximum temperature set point that can be programmed

into the standard control module from the Operator Interface

on a heating boiler is 220°F (104.4°C). The manual reset high

limit control for a heating boiler is adjustable up to a fixed

maximum setting of 230°F (110°C).

The maximum temperature set point for a water heater is 190°F

(88°C). The auto reset high limit is fixed at 200°F (93°C), and

the adjustable manual reset high limit has a maximum setting of

230°F (110°C).

A 120 VAC, 15 Amp, 1 ph, 60 Hz circuit is required for operation

of the appliance controls.

The appliance, when installed, must be electrically grounded in

accordance with the requirements of the authority having

jurisdiction or in the absence of such requirements, with the

latest edition of the National Electrical Code ANSI/NFPA No.

70. When the unit is installed in Canada, it must conform to the

CAE C22.1, Canadian Electrical Code, Part I and/or local

Electrical Codes. Multiple units connected in a Cascade must be

grounded to the same ground connection.

1. All wiring between the appliance and field installed devices

shall be made with type T wire [63°F (35°C) rise].

2. All line voltage wire exterior to the appliance must be

enclosed in approved conduit or approved metal clad

cable.

3. The circulating pump must run continuously when the

appliance is being fired.

4. To avoid serious damage, DO NOT energize the appliance

until the system is full of water. Ensure that all air is

removed from the heat exchanger and piping before

beginning initial operation. Serious damage may result if

the appliance is operated without proper flow.

5. Provide the appliance with proper overload protection.

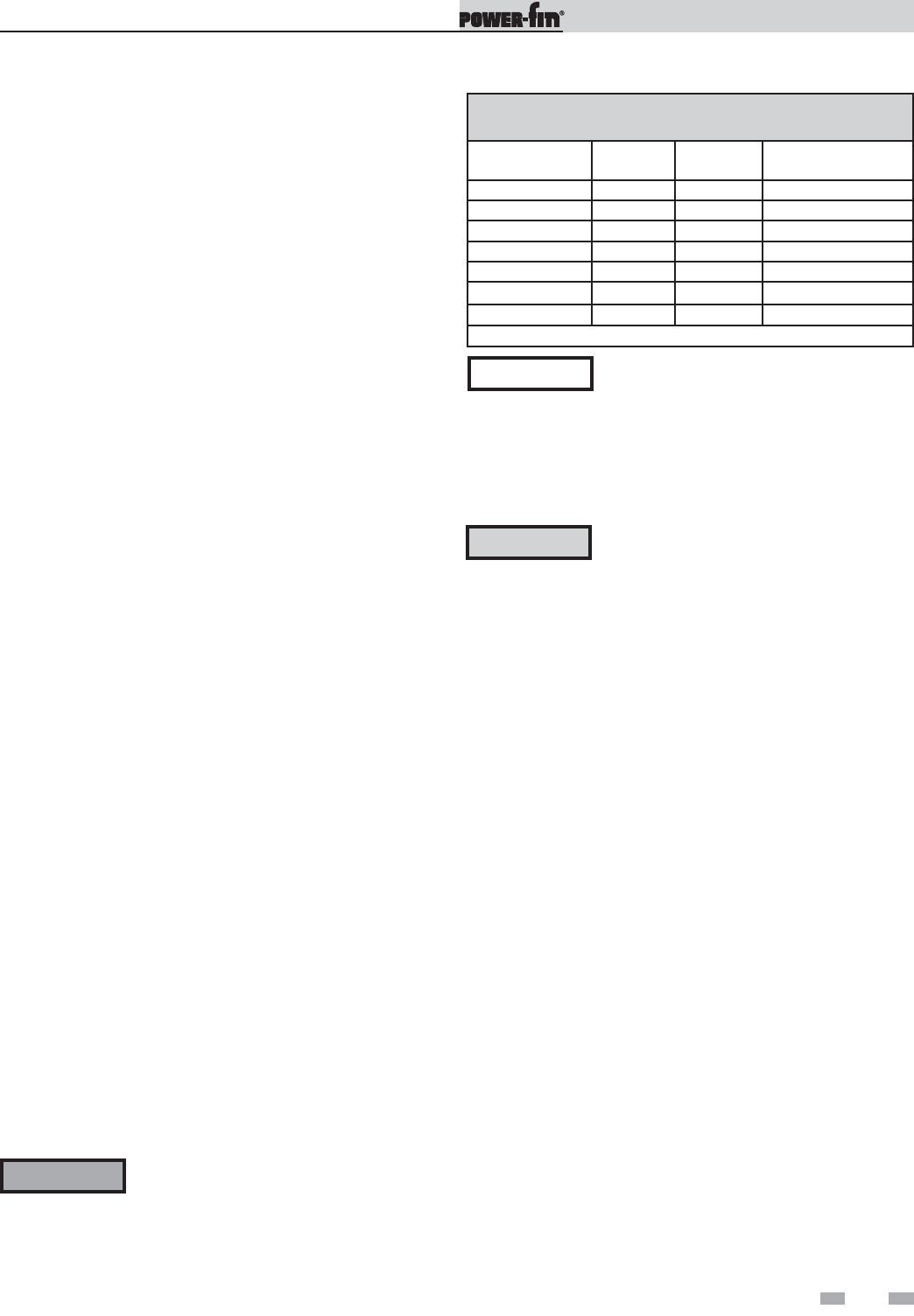

TABLE - 5A

AMP DRAW DATA

Model

Blower &

Controls

Pump FLA*

Approximate Total

Amps @ 120 VAC

502 6.7 8.8 15.5

752 6.7 8.8 15.5

1002 6.7 8.8 15.5

1302 6.7 8.8 15.5

1501 6.5 8.8 15.3

1701 6.5 8.8 15.3

2001 6.5 8.8 15.3

*Standard Pump Supplied with Water Heaters Only

ELECTRICAL SHOCK HAZARD – For your

safety, turn off electrical power supply before

making any electrical connections to avoid

possible electric shock hazard. Failure to do

so can cause severe personal injury or death.

Wiring must be N.E.C. Class 1.

If original wiring as supplied with the boiler

must be replaced, use only type 105°C wire or

equivalent.

Boiler must be electrically grounded as

required by National Electrical Code

ANSI/NFPA 70 – latest edition.

Label all wires prior to disconnection when

servicing controls. Wiring errors can cause

improper and dangerous operation.

ƽ WARNING

NOTICE

ƽ CAUTION

Installation must comply with:

1. National Electrical Code and any other national, state,

provincial, local codes, or regulations.

2. In Canada, CSA C22.1 Canadian Electrical Code Part 1, and

any local codes.

Line voltage connections

1. Connect 120 VAC power wiring to the line voltage terminal

strip in the junction box, as shown in FIG. 5-1.

2. Provide and install a fused disconnect or service switch

(15 AMP recommended) as required by the code (see

FIG. 5-1).

3. To activate a system pump, wire as shown in FIG. 5-1. If the

motor is larger than 1 HP, you must install a contactor.

4. When connecting power to units which are to be cascaded,

each unit must be connected to the same ground

connection.

43

Installation & Operation Manual