A-12

MDrive 34Plus

Microstepping Hardware - Revision R071108

Relevant to Firmware Version 3.0.02

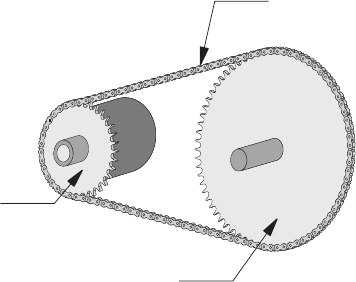

Chain Drive

In a system with a chain drive, the following must be considered:

the weight and size of drive sprocket and any attaching hub

the weight and size of the driven sprocket and shaft

the weight of the chain

the weight of any material or parts being moved

Once the system inertia (J

L

) has been calculated in oz-in-sec

2

, it can be matched to the motor inertia. To

match the system inertia to the motor inertia, divide the system inertia by the square of the gearbox ratio.

The result is called Reflected Inertia or (J

ref

).

J

ref

= J

L

÷Ζ

2

Where:

J

L

= System Inertia in oz-in-sec

2

J

ref

= Reflected Inertia in oz-in-sec

2

Z = Gearbox Ratio

The ideal situation would be to have a 1:1 system inertia to motor inertia ratio. This will yield the best

positioning and accuracy. The reflected inertia (J

ref

) must not exceed 10 times the motor inertia.

Your system may require a reflected inertia ratio as close to 1:1 as possible. To achieve the 1:1 ratio, you

must calculate an Optimal Gearbox Ratio (Z

opt

) which would be the square root of J

L

divided by the

desired J

ref

. In this case since you want the system inertia to match the motor inertia with a 1:1 ratio, J

ref

would be equal to the motor inertia.

Z

opt

= J

L

÷ J

ref

Where:

Z

opt

= Optimal Gearbox Ratio

J

L

= System Inertia in oz-in-sec

2

J

ref

= Desired Reflected Inertia in oz-in-sec

2

(Motor Inertia)

Weight of

chain

Weight and size

of drive

sprocket and hub

Weight and size

of driven sprocket,

shaft and any material

or parts being moved

Figure B.6: Chain Drive System Inertia Considerations