21 300381000

1. Disconnect electrical power from Cooling Unit at disconnect switch.

2. Remove two screws securing Cooling Unit top cover, then remove cover.

3. Using flashlight, inspect ice water bath and ice bank for cleanliness, ice water bath should be clear and ice

bank free of foreign particles.

4. If cleaning of water tank is necessary, refer to CHANGING ICE WATER BATH in this section.

5. Fill water tank with clean water until water starts flowing from water tank overflow hose. USE LOW

MINERAL CONTENT WATER WHERE A LOCAL WATER PROBLEM EXISTS.

6. Install Cooling Unit top cover and secure with two screws.

7. Restore electrical power to Cooling Unit at disconnect switch.

CHANGING ICE WATER BATH

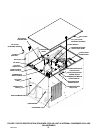

(see Figures 5 or 6)

1. Disconnect electrical power from Cooling Unit at disconnect switch.

2. Close shutoff valve in plain water inlet supply line.

3. Remove two screws securing the Cooling Unit top cover, then remove the cover.

4. Make sure end of water tank drain hose is routed to the floor drain, then remove plug from end of hose and

allow water to drain from water tank.

CAUTION: Never use an ice pick or other instrument to remove ice from evaporator coils.

Such practice can result in punctured refrigeration circuit.

5. Allow ice bank to melt. Hot water may be used to speed melting.

6. Thoroughly rinse inside of water tank with clean water.

7. Install plug in end of water tank drain hose.

8. Open shutoff valve in plain water inlet supply line. Due to slow water fill rate of the water level float control,

the water tank may be hand filled until water runs out of the overflow tube. USE LOW MINERAL

CONTENT WATER WHERE A LOCAL WATER PROBLEM EXISTS.

9. Install Cooling Unit top cover and secure with two screws.

10. Connect electrical power to Cooling Unit at disconnect switch.

WATER PUMP YEARLY MAINTENANCE (OR AFTER WATER SYSTEM DISRUPTIONS)

WARNING: The carbonators water inlet strainer screens, double liquid check valves, and

carbonated water tanks water outlet lines single check valves, must be inspected and

serviced at least once a year under normal circumstances, and after any disruptions

(plumbing work, earthquake, etc.) to the water supply system that might cause turbulent (erratic)

flow of water through system. Water pump with no screen or defective screen in the strainer would

allow foreign particles to foul the liquid double check valve. CO

2

gas could then back flow into

water system and create a health hazard in water system.