2-99 6 21322L

INSTALLATION AND REPAIR SHOULD BE DONE BY A QUALIFIED SERVICE PERSON. THE APPLIANCE

SHOULD BE INSPECTED BEFORE USE AND AT LEAST ANNUALLY BY A QUALIFIED SERVICE PERSON.

MORE FREQUENT CLEANING MAY BE REQUIRED DUE TO EXCESSIVE LINT FROM CARPETING, BED-

DING MATERIAL, ETC. IT IS IMPERATIVE THAT CONTROL COMPARTMENTS, BURNERS AND CIRCU-

LATING AIR PASSAGEWAYS OF THE APPLIANCE BE KEPT CLEAN.

DUE TO HIGH TEMPERATURES, THE APPLIANCE SHOULD BE LOCATED OUT OF TRAFFIC AND AWAY

FROM FURNITURE AND DRAPERIES.

WARNING!

THIS APPLIANCE MAY ONLY USE THE DIRECT VENT CHIMNEY SYSTEM DESIGNED FOR USE

WITH THE UNIT AND MUST NOT BE CONNECTED TO A CHIMNEY FLUE SERVICING A SEPA-

RATE SOLID FUEL OR GAS FUEL BURNING APPLIANCE.

GC150 SERIES DIRECT VENT GAS APPLIANCE

IV. PRE-INSTALLATION PREPARATION

A. GAS PRESSURE

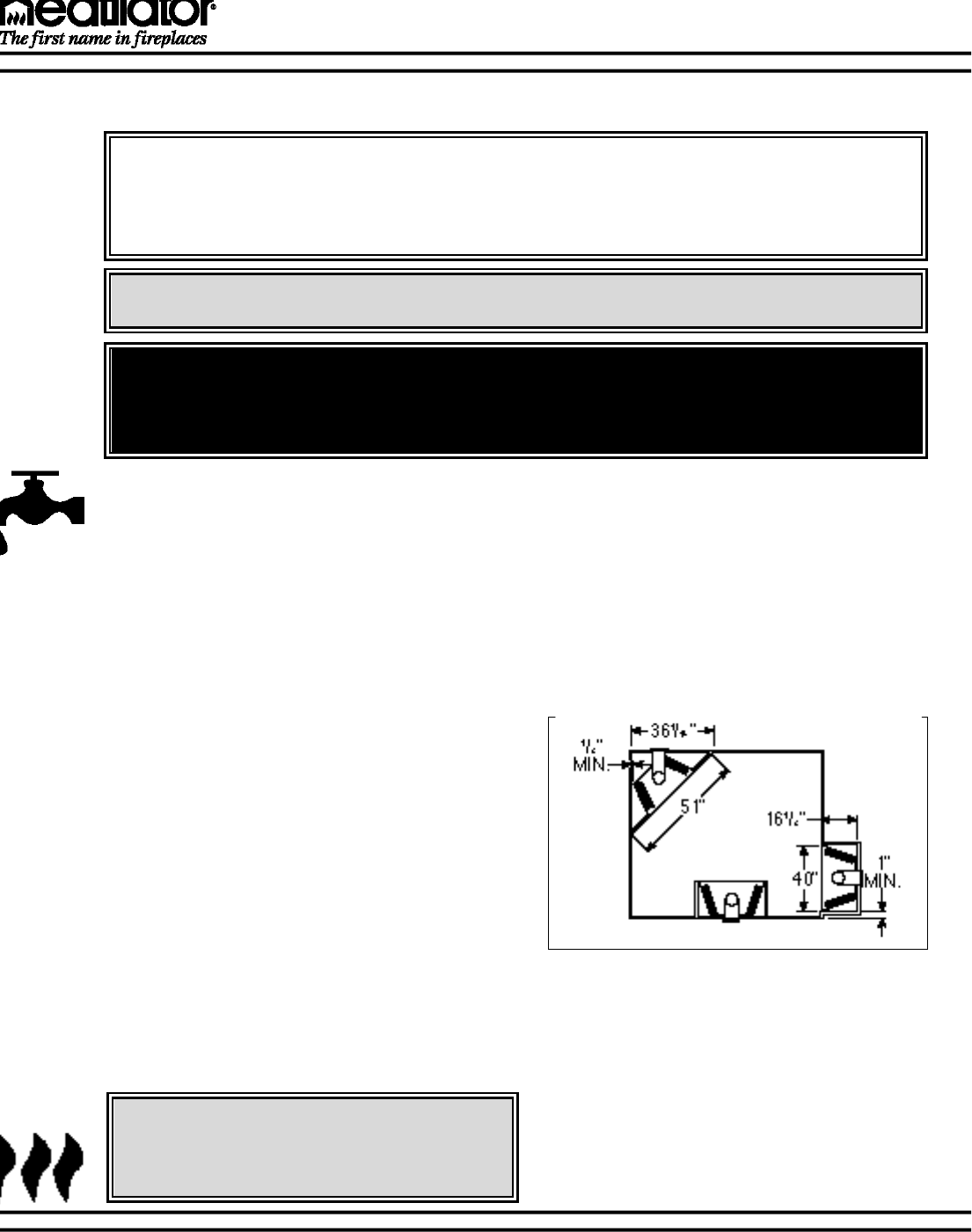

C. FIREPLACE LOCATIONS AND

SPACE REQUIREMENTS

This appliance may be installed along a wall, across a

corner or use an exterior chase. The GC150 Series

may be installed at a height level with the floor, or it

can be raised up from the floor to enhance its visual

impact. Figure 1 illustrates a variety of ways the

appliance may be located in a room. These appli-

ances are also certified for installation in a bedroom

or bed/sitting room in the U.S.

For natural gas, the minimum inlet gas supply pressure is

4.5 inches water column, and the maximum inlet gas pres-

sure is 7.0 inches water column, for the purpose of input

adjustment. Input rate is 22,500 Btu/hr. For propane gas,

the inlet gas supply pressure must be at least 11.0 inches

water column and a maximum 14.0 inches water column.

(See CKP Natural Gas to Propane Gas Conversion Kit

installation instructions.)

A 1/8" NPT plugged tapping is provided on the gas control

valve, near the outlet to the main burner immediately

upstream of the gas supply connection to the appliance,

accessible for a test gage connection .

Optimum manifold pressure is 3.5 inches water column for

natural gas and 10.5 inches water column for propane gas.

B. HIGH ALTITUDE INSTALLATION

For U.S. installation, units are tested and approved for ele-

vations from 0-2000 feet.

When installing this unit at an elevation above 2000 feet,

United States codes require a decrease of the input rating

by changing the existing burner orifice to a smaller size.

Input should be reduced 4 percent for each 1000 feet

above sea level. Check with the local gas utility for proper

orifice size identification. This unit uses a .093in. /2.36

mm. orifice size on natural gas versions and a .056 in./1.42

mm. orifice size on propane gas converted versions.

Consult your local gas company for assistance in determin-

ing the proper orifice for your location or refer to ANSI

Z223.1-latest edition, Appendix F.

Figure 1

Fireplace Locations and Clearances

D. CLEARANCES

The following clearances to combustibles must be

maintained: Minimum clearances to the top standoffs

of the unit - 0", floor - 0", back - 1/2", sides - 1/2", top

of the hood to ceiling - 30". Minimum clearances to

venting are as follows: Horizontal runs require a 3"

minimum air space on the top and a 1" minimum air

space on the sides and bottom of the vent section.

Vertical rise sections require a 1" minimum air space

completely around the vent sections.

CAUTION:

DO NOT EXPOSE THE UNIT TO THE

ELEMENTS (SUCH AS RAIN, ETC.).