SERVICING

36

NOTE: R410A should be drawn out of the storage container or

drum in liquid form due to its fractionation properties, but should

be "Flashed" to its gas state before entering the system. There

are commercially available restriction devices that fit into the

system charging hose set to accomplish this. DO NOT charge

liquid R410A into the compressor.

4. With the system still running, close the valve on the charg-

ing cylinder. At this time, you may still have some liquid

refrigerant in the charging cylinder hose and will definitely

have liquid in the liquid hose. Reseat the liquid line core.

Slowly open the high side manifold valve and transfer the

liquid refrigerant from the liquid line hose and charging cyl-

inder hose into the suction service valve port. CAREFUL:

Watch so that liquid refrigerant does not enter the com-

pressor.

Final Charge Adjustment

The outdoor temperature must be 60°F or higher. Set the room

thermostat to COOL, fan switch to AUTO, and set the tem-

perature control well below room temperature.

After system has stabilized per startup instructions, compare

the operating pressures and outdoor unit amp draw to the num-

bers listed in the technical manual. If pressures and amp draw

are too low, add charge. If pressures and amp draw are too

high, remove charge. Check subcooling and superheat as de-

tailed in the following section.

5. With the system still running, remove hose and reinstall

both valve caps.

6. Check system for leaks.

Due to their design, Scroll compressors are inherently more

tolerant of liquid refrigerant.

NOTE: Even though the compressor section of a Scroll com-

pressor is more tolerant of liquid refrigerant, continued flood-

back or flooded start conditions may wash oil from the bearing

surfaces causing premature bearing failure.

S-104 CHECKING COMPRESSOR

EFFICIENCY

The reason for compressor inefficiency is broken or damaged

suction and/or discharge valves, or scroll flanks on Scroll com-

pressors, reducing the ability of the compressor to pump re-

frigerant vapor.

The condition of the valves or scroll flanks is checked in the

following manner.

1. Attach gauges to the high and low side of the system.

2. Start the system and run a Cooling Performance Test.

If the test shows-

⇒ Below normal high side pressure.

⇒

Above normal low side pressure.

⇒

Low temperature difference across coil.

⇒ Low amp draw at compressor.

-and the charge is correct. The compressor is faulty - replace

the compressor.

S-105 THERMOSTATIC EXPANSION VALVE

The expansion valve is designed to control the rate of liquid

refrigerant flow into an evaporator coil in exact proportion to the

rate of evaporation of the refrigerant in the coil. The amount of

refrigerant entering the coil is regulated since the valve responds

to temperature of the refrigerant gas leaving the coil (feeler bulb

contact) and the pressure of the refrigerant in the coil. This

regulation of the flow prevents the return of liquid refrigerant to

the compressor.

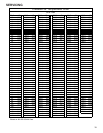

The illustration below shows typical heatpump TXV/check valve

operation in the heating and cooling modes.

COOLING HEATING

TXV VALVES

Some TXV valves contain an internal check valve thus eliminat-

ing the need for an external check valve and bypass loop. The

three forces which govern the operation of the valve are: (1) the

pressure created in the power assembly by the feeler bulb, (2)

evaporator pressure, and (3) the equivalent pressure of the su-

perheat spring in the valve.

0% bleed type expansion valves are used on indoor and out-

door coils. The 0% bleed valve will not allow the system pres-

sures (High and Low side) to equalize during the shut down

period. The valve will shut off completely at approximately 100

PSIG.

30% bleed valves used on some other models will continue to

allow some equalization even though the valve has shut-off

completely because of the bleed holes within the valve. This

type of valve should not be used as a replacement for a 0%

bleed valve, due to the resulting drop in performance.

The bulb must be securely fastened with two straps to a clean

straight section of the suction line. Application of the bulb to a

horizontal run of line is preferred. If a vertical installation can-

not be avoided, the bulb must be mounted so that the capillary

tubing comes out at the top.

THE VALVES PROVIDED BY GOODMAN ARE DESIGNED

TO MEET THE SPECIFICATION REQUIREMENTS FOR OP-

TIMUM PRODUCT OPERATION. DO NOT USE SUBSTI-

TUTES.