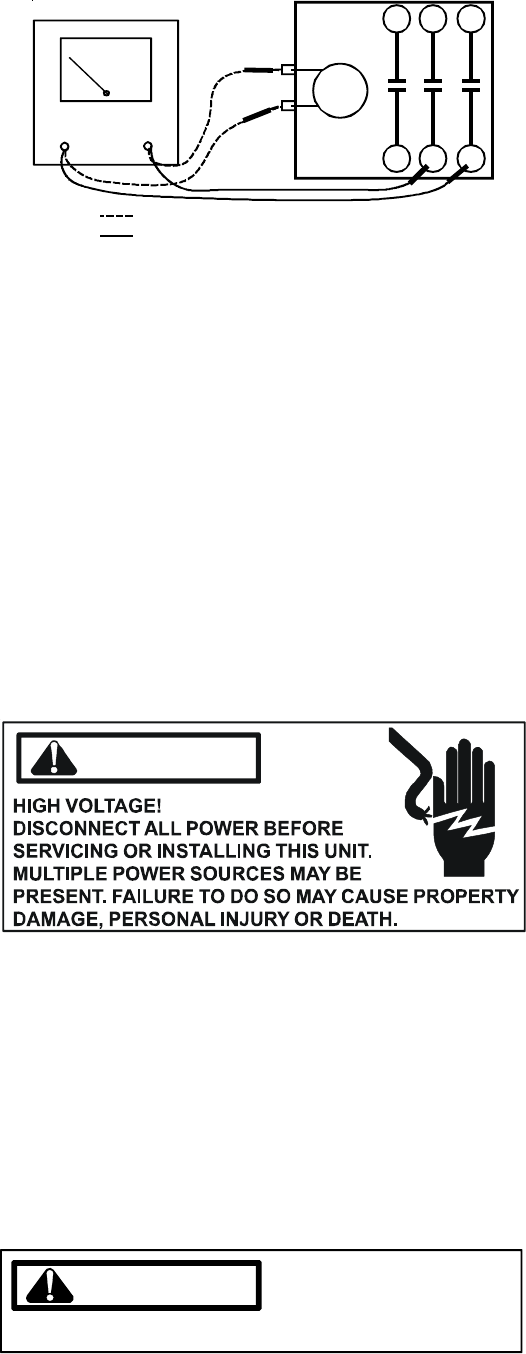

SERVICING

25

VOLT/OHM

METER

CC

Ohmmeter for testing holding coil

Voltmeter for testing contacts

T1

L1

T3

L3

T2

L2

TESTING COMPRESSOR CONTACTOR

(Three-phase)

S-11 CHECKING LOSS OF CHARGE

PROTECTOR

(Heat Pump Models)

The loss of charge protector senses the pressure in the liquid

line and will open its contacts on a drop in pressure. The low

pressure control will automatically reset itself with a rise in

pressure.

The low pressure control is designed to cut-out (open) at ap-

proximately 50 PSIG. It will automatically cut-in (close) at

approximately 95 PSIG.

Test for continuity using a VOM and if not as above, replace

the control.

S-12 CHECKING HIGH PRESSURE CONTROL

WARNING

The high pressure control capillary senses the pressure in the

compressor discharge line. If abnormally high condensing pres-

sures develop, the contacts of the control open, breaking the

control circuit before the compressor motor overloads. This

control is automatically reset.

1. Using an ohmmeter, check across terminals of high pres-

sure control, with wire removed. If not continuous, the con-

tacts are open.

3. Attach a gauge to the dill valve port on the base valve.

With power ON:

WARNING

LINE VOLTAGE NOW PRESENT.

4. Start the system and place a piece of cardboard in front of

the condenser coil, raising the condensing pressure.

5. Check pressure at which the high pressure control cuts-

out.

If it cuts-out at 610 PSIG ± 10 PSIG, it is operating normally

(See causes for high head pressure in Service Problem Analy-

sis Guide). If it cuts out below this pressure range, replace the

control.

S-15 CHECKING CAPACITOR

CAPACITOR, RUN

A run capacitor is wired across the auxiliary and main wind-

ings of a single phase permanent split capacitor motor. The

capacitors primary function is to reduce the line current while

greatly improving the torque characteristics of a motor. This is

accomplished by using the 90° phase relationship between

the capacitor current and voltage in conjunction with the motor

windings so that the motor will give two phase operation when

connected to a single phase circuit. The capacitor also re-

duces the line current to the motor by improving the power

factor.

CAPACITOR, START

SCROLL COMPRESSOR MODELS

Hard start components are not required on Scroll compressor

equipped units due to a non-replaceable check valve located in

the discharge line of the compressor. However hard start kits

are available and may improve low voltage starting characteris-

tics. Only hard start kits approved by Goodman

®

or Copeland

should be used. "Kick Start" and/or "Super Boost" kits are not

approved start assist devices.

This check valve closes off high side pressure to the compres-

sor after shut down allowing equalization through the scroll

flanks. Equalization requires only about one or two seconds

during which time the compressor may turn backwards.

MODELS EQUIPPED WITH A HARD START DEVICE

A start capacitor is wired in parallel with the run capacitor to

increase the starting torque. The start capacitor is of the elec-

trolytic type, rather than metallized polypropylene as used in

the run capacitor.

A switching device must be wired in series with the capacitor

to remove it from the electrical circuit after the compressor

starts to run. Not removing the start capacitor will overheat the

capacitor and burn out the compressor windings.