Version 1.0b

30

TROUBLE-SHOOTING GUIDE

The 820 Nova millivolt control valve is available in three different configurations. They are the (1)

Millvolt Plus vented, or the (2) Millivolt Plus vent-free, or the (3) Millivolt systems.

The Millivolt Plus vented system is for use in direct vent appliances that require fast shut-off in the

even of a pilot flame failure. A thermocouple powers the safety magnet and a thermopile powers the

main control valve.

The Millivolt Plus vent-free system is used in conjunction with an ODS pilot. As with the vented

Millivolt Plus control valve, this valve uses a thermocouple to power the safety magnet and uses a

thermopile to power the main control valve.

The Millivolt system is used with gravity vented appliances where rapid shut-off is not necessary in the

event of a pilot flame outage. It uses a single thermopile to power both the safety magnet circuit and

the main control valve. A spill switch could be used in the safety magnet circuit of this system.

All NOVA control valves are fitted with a safety interlock device that prevents unsafe ignition of the

pilot burner after the ON/PILOT/OFF control knob is turned to the OFF position. All three of these

control valves can accommodate a wall switch, or a wall thermostat, or a remote control unit that can be

used to cycle the main control valve on and off. Following is the electrical data for the 820 Nova

millivolt gas control valve models:

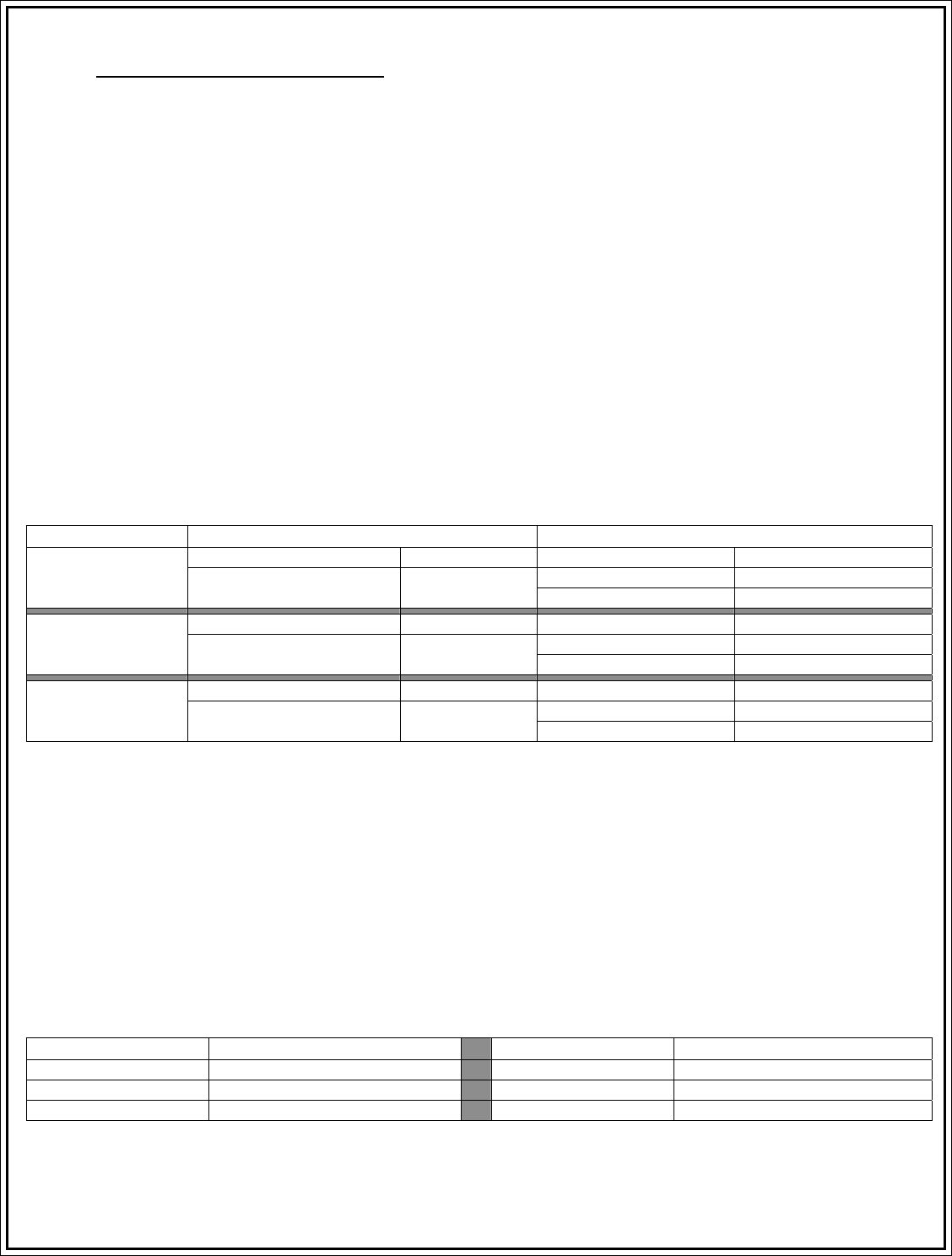

VALVE TYPE MAIN CONTROL VALVE SAFETY MAGNET

Minimum Voltage 145 mV Hold-in current Less than 285mA

Drop-out current Greater than 125mA

NOVA mV Plus

Vented

Coil Resistance 2.25Ω±0.5Ω

Coil resistance 0.018Ω±0.003Ω

Minimum Voltage 145 mV Hold-in current Less than 200mA

Drop-out current Greater than 80mA

NOVA mV Plus

Un-vented

Coil Resistance 2.25Ω±0.5Ω

Coil resistance 0.018Ω±0.003Ω

Minimum Voltage 145 mV Hold-in current Less than 12mA

Drop-out current Greater than 4mA

NOVA Millivolt

Vented

Coil Resistance 2.25Ω±0.5Ω

Coil resistance 10.2Ω±0.05Ω

All millivolt control valve circuits are easily affected by electrical resistance. If enough resistance is

present in the appliances circuit, two things can occur. (A) Either the main control valve will work

intermittently and be unpredictable or (B) the main control valve will not work at all. There are several

areas where excess resistance can be found in the appliances circuit. In new installations, the

thermostat itself can be found to be the problem. Always use a thermostat rated for millivolt control as

they have been designed to minimize circuit resistance. The other area to check is the wiring itself.

Wire gage plays an important part in wire resistance. The smaller the diameter of the wire and the

greater the length of the wire, the larger the circuit resistance will be. The table above provides

valuable information to select the proper wire that is used to connect to the main control valve. This

table refers to the total length of wire from the control valve out to the thermostat and back to the

control valve. All electrical connections must be tight, clean, and free from corrosion. Corrosion can

build up over time due to humidity problems so inspect wire connections on an annual basis.

WIRE SIZE MAXIMUM LENGTH WIRE SIZE MAXIMUM LENGTH

12 Gauge 150 feet 18 Gauge 40 feet

14 Gauge 100 feet 20 Gauge 25 feet

16 Gauge 64 feet 22 Gauge 16 feet