Version 1.0b

29

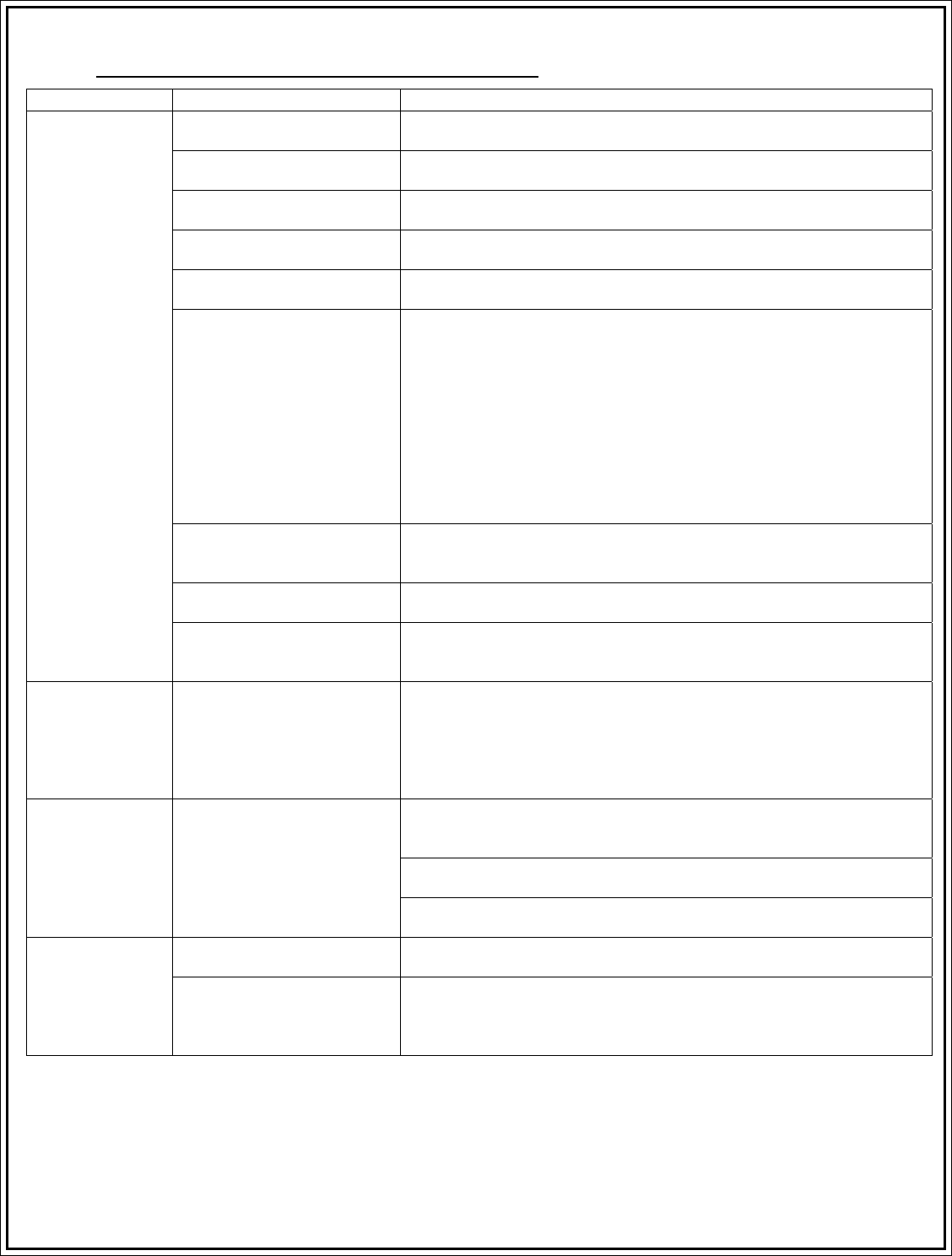

TROUBLESHOOTING INSTRUCTIONS (cont’d)

PROBLEM POSSIBLE CAUSE SOLUTION

Gas pressure to appliance is

low.

Refer to Item #2 in the Set-Up Guide.

Pilot not lit. Light pilot and wait for thermopile to heat up sufficiently to power the main

operator. If pilot fails to light, or hold, refer to above sections.

Control knob not in ON

position.

Rotate OFF/PILOT/ON control knob to the ON position.

Thermostat not in the ON

position.

Turn thermostat to ON, and adjust temperature control to call for heat.

Thermopile output voltage not

within design parameters.

Refer to Item #7 in the Set-Up Guide. If unable to meet minimum

thermopile requirements, replace thermopile.

Defective thermostat or

thermostat wiring.

(A) With the pilot adjusted properly, (Refer to Item #7 in the Set-Up

Guide) place a jumper wire between TPTH and TH. Measure the

voltage (millivolt) reading across the TPTH and TP terminals on

the control valve. This voltage should not fall below 300mV.

Record reading.

(B) Remove the jumper wire from the TPTH and TH connections and

reconnect the thermostat wires to the same terminals. Measure the

voltage (millivolt) reading across the TPTH and TP terminals on

the control valve. This voltage should not fall below 150mV. If

reading is below 150mV the source of excessive resistance must

be located and removed. (bad connections or bad wires)

Defective wall switch. Repeat the troubleshooting items covered under “Defective thermostat or

thermostat wiring,” Use the exact same procedures but substitute the word

“wall switch” where the word thermostat appears.

Excessive wire resistance. Make certain that all mV connections are made using wire of the proper

AWG size. (Refer to the Trouble-Shooting Guide.)

No gas to main

burner.

Thermostat or

wall switch will

not cycle main

burner

Valve wired wrong. Thermopile leads must be connected to the TPTH and the TP connection of

the main control valve. Thermostat wires must be connected to the TPTH

and the TH terminals of the main control valve.

Main operator coil defective. Verify the electrical resistance of the main control valve operator coil in the

following manner:

(A) Remove all wires from the control valve head.

(B) With an ohmmeter, measure the electrical resistance between TP

and TH terminals. If the resistance does not fall within

specifications shown in the Troubleshooting Guide, replace valve.

Check the appliances installation instructions provided by the manufacturer

to verify that the proper flue dimensions are within specification and that

proper combustion make-up air is provided for the particular appliance.

Verify that the appliance’s flue ins installed according to manufacturer’s

instructions.

Main burner

cycles on and off.

System not on

thermostat.

Flue gas spillage present in

combustion chamber. (Non-

DV appliances only)

Check the flue or the combustion air intake for blockage. Clean as

necessary.

Debris or damage to seat of

main valve.

Replace the control valve assembly. Main burner lights

in the PILOT

position of the

control valve.

Main seat blown out because

of exposing LPG gas valve to

unregulated line pressure in

excess of 15 psig.

Replace the control valve assembly.