Version 1.0b

24

GENERAL PERIODIC INSPECTIONS

Check the venting system annually and make sure the system is clear of any debris. Check flame patterns

periodically. Allow 15 minutes for a flame to reach maximum color and height.

GENERAL CLEANING, PAINTED SURFACES

Occasionally dry rag dust the Inglenook to keep the painted surface looking new. Paint can be touched up

as needed. Clean any area to be painted with fine steel wool. Remove all trim or cover all trim and controls

with masking tape. Then, touch up the stove with Stove Bright

®

high temperature stove paint. Do not over

paint as this will only lead to paint peeling problems.

GENERAL CLEANING, PLATED SURFACES

When cleaning plated trim, use special care to avoid damage. Do not use chemical or abrasive cleaners.

Wipe only with a very soft damp cotton cloth to maintain original brilliance. CAUTION: Vigorous wiping

may remove or discolor the plated finish.

MAIN ORIFICES

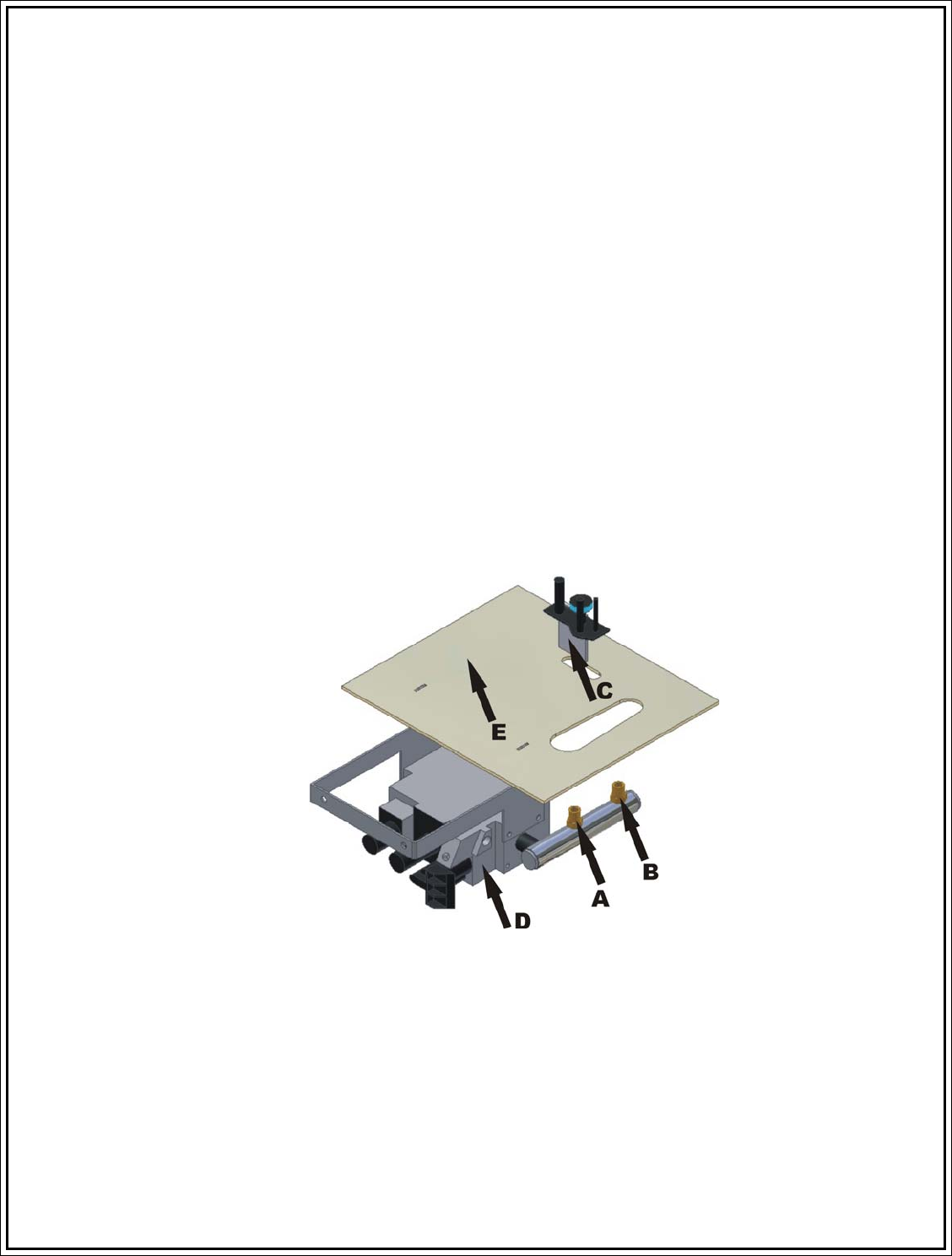

FIGURE 23 shows the valve plate assembly, Item E. This part is installed in the combustion chamber of

the Inglenook fireplace. The pilot assembly, Item C, comes preinstalled into Item E. Inspect the wiring of

the pilot assembly before installation to ensure all wires are properly connected to the gas valve. The gas

control valve, Item D must be plumbed to the gas line cut-off valve that has been installed in the lower

chamber of the Inglenook. The front burner spud orifice (Item A) and the rear burner spud orifice (Item B)

need to be installed according to the fuel type that will be used. Refer to TABLE 3 to obtain the correct

orifice size for both fuel and altitude requirements that site-specific location dictates. Item A and Item B are

the front and rear spud orifices. Inspect them for the proper size for the gas being used.

FIGURE 23: BURNER ASSEMBLY

GAS FLAME INSPECTION

The flames will be blue during the first 5 minutes or so but over a period of 15 minutes, the flame will

gradually turn yellow. Flame intensity and the glowing logs vary with the specific type of fuel and venting

conditions. Refer to FIGURE 5d for a picture that shows a proper flame for natural gas.

IMPORTANT INFORMATION: IT IS NORMAL FOR GAS PRODUCTS, FABRICATED FROM

STEEL, TO GIVE OFF SOME EXPANSION AND/OR CONTRACTION NOISES DURING THE

START UP OR COOL DOWN CYCLE. SIMILAR NOISES ARE HEARD IN A FURNACE HEAT

EXCHANGER OR CAR ENGINE.