7

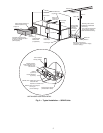

Step 4 — Mounting the Unit — Horizontal units

should be mounted using the factory-installed hangers. Proper

attachment of hanging rods to building structure is critical for

safety. See Fig. 2 and 5. Rod attachments must be able to sup-

port the weight of the unit. See Table 1 for unit operating

weights.

Step 5 — Duct System — Size the duct system to han-

dle the design airflow quietly.

NOTE: Depending on the unit, the fan wheel may have a ship-

ping support installed at the factory. This must be removed

before operating unit.

SOUND ATTENUATION — To eliminate the transfer of

vibration to the duct system, a flexible connector is recom-

mended for both discharge and return air duct connections on

metal duct systems. The supply and return plenums should

include internal duct liner of fiberglass or be made of duct

board construction to maximize sound attenuation of the

blower. Installing the WSHP unit to uninsulated ductwork in an

unconditioned space is not recommended since it will sweat

and adversely affect the unit’s performance.

To reduce air noise, at least one 90 degree elbow could be

included in the supply and return air ducts, provided system

performance is not adversely impacted. The blower speed can

also be changed in the field to reduce air noise or excessive air-

flow, provided system performance is not adversely impacted.

EXISTING DUCT SYSTEM — If the unit is connected to

existing ductwork, consider the following:

• Verify that the existing ducts have the proper capacity to

handle the unit airflow. If the ductwork is too small,

install larger ductwork.

• Check existing ductwork for leaks and repair as

necessary.

NOTE: Local codes may require ventilation air to enter the

space for proper indoor air quality. Hard-duct ventilation may

be required for the ventilating air supply. If hard ducted venti-

lation is not required, be sure that a proper air path is provided

for ventilation air to unit to meet ventilation requirement of the

space.

Step 6 — Condensate Drain — Slope the unit to-

ward the drain at a 6.5 mm per 30 cm pitch. See Fig. 6. If it is

not possible to meet the required pitch, install a condensate

pump at the unit to pump condensate to building drain.

Horizontal units are not internally trapped; therefore an ex-

ternal trap is necessary. Install each unit with its own individual

trap and means to flush or blowout the condensate drain line.

Do not install units with a common trap or vent. For typical

condensate connections see Fig. 7.

NOTE: Never use a pipe size smaller than the connection.

VENTING — Install a vent in the condensate line of any

application that may allow dirt or air to collect in the line. Con-

sider the following:

• Always install a vent where an application requires a

long horizontal run.

• Always install a vent where large units are working

against higher external static pressure and to allow

proper drainage for multiple units connected to the same

condensate main.

• Be sure to support the line where anticipated sagging from

the condensate or when “double trapping” may occur.

• If condensate pump is present on unit, be sure drain con-

nections have a check valve to prevent back flow of con-

densate into other units.

Compressor

Section

Air Handler

Section

B

A

C

E

D

D

Fig. 5 — Horizontal Hanger Bracket

(Factory Installed)

50RHE UNITS

DIMENSIONS (mm)

ABCDE

006-024 568 1095 619 1095 518

030,036 568 1349 619 1349 518

042,048 568 1577 619 1577 518

060 645 1806 695 1806 594

65 mm Pitch for

Drainage

Pitch Toward

Drain

Drain Connection

Fig. 6 — Horizontal Unit Pitch

NOTE: Trap should be deep enough to offset maximum unit static

difference. A 102 mm trap is recommended.

Fig. 7 — Trap Condensate Drain