22

Output EH2 will be off if FP1 is greater than 7.2 C and FP2

(when shorted) is greater than 43.3 C during Heating Stage 3

mode. This condition will have a 30-second recognition time.

Also, during Heating Stage 3 mode, EH1, EH2, Fan Enable,

and Fan Speed will be ON if G input is not active.

EMERGENCY HEAT — In Emergency Heat mode, the Fan

Enable and Fan Speed relays are turned on. The EH1 output is

turned on immediately. With continuing Emergency Heat de-

mand, EH2 will turn on after 5 minutes. Fan Enable and Fan

Speed relays are turned off after a 60-second delay. The control

reverts to Standby mode.

Output EH1, EH2, Fan Enable, and Fan Speed will be ON if

the G input is not active during Emergency Heat mode.

COOLING STAGE 1 — In Cooling Stage 1 mode, the Fan

Enable, compressor and RV relays are turned on immediately.

If configured as stage 2 (DIP switch set to OFF) then the com-

pressor and fan will not turn on until there is a stage 2 demand.

The fan Enable and compressor relays are turned off immedi-

ately when the Cooling Stage 1 demand is removed. The con-

trol reverts to Standby mode. The RV relay remains on until

there is a heating demand. If there is a master/slave or dual

compressor application, all compressor relays and related func-

tions will track with their associated DIP switch 2 on S1.

COOLING STAGE 2 — In Cooling Stage 2 mode, the Fan

Enable, compressor and RV relays remain on. The Fan Speed

relay is turned on immediately and turned off immediately

once the Cooling Stage 2 demand is removed. The control re-

verts to Cooling Stage 1 mode. If there is a master/slave or dual

compressor application, all compressor relays and related func-

tions will track with their associated DIP switch 2 on S1.

NIGHT LOW LIMIT (NLL) STAGED HEATING — In NLL

staged Heating mode, the override (OVR) input becomes ac-

tive and is recognized as a call for heating and the control will

immediately go into a Heating Stage 1 mode. With an addition-

al 30 minutes of NLL demand, the control will go into Heating

Stage 2 mode. With another additional 30 minutes of NLL

demand, the control will go into Heating Stage 3 mode.

SYSTEM TEST

System testing provides the ability to check the control

operation. The control enters a 20-minute Test mode by

momentarily shorting the test pins (see Fig. 9-12). All time

delays are reduced by a factor of 15.

Test Mode — To enter Test mode on C or D controls, cycle

the power 3 times within 60 seconds. The LED (light-emitting

diode) will flash a code representing the last fault when enter-

ing the Test mode. The alarm relay will also power on and off

during Test mode. See Tables 13 and 14. To exit Test mode,

short the terminals for 3 seconds or cycle the power 3 times

within 60 seconds.

NOTE: Deluxe D Control has a flashing code and alarm relay

cycling code that will both have the same numerical label.

For example, flashing code 1 will have an alarm relay cycling

code 1. Code 1 indicates the control has not faulted since the

last power off to power on sequence.

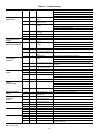

Table 13 — C Control Current LED Status

and Alarm Relay Operations

LEGEND

NOTES:

1. Slow flash is 1 flash every 2 seconds.

2. Fast flash is 2 flashes every 1 second.

3. EXAMPLE: “Flashing Code 2” is represented by 2 fast flashes followed by

a 10-second pause. This sequence will repeat continually until the fault is

cleared.

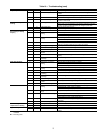

Table 14 — C Control LED Code and

Fault Descriptions

LEGEND

LED STATUS DESCRIPTION OF OPERATION ALARM RELAY

On

NormalMode Open

Normal Mode with

PM Warning

Cycle

(closed 5 sec.,

Open25 sec.)

Off C Control is non-functional Open

Slow Flash Fault Retry Open

Fast Flash Lockout Closed

Slow Flash Over/Under Voltage Shutdown

Open

(Closed after

15 minutes)

Flashing Code 1 Test Mode — No fault in memory Cycling Code 1

Flashing Code 2 Test Mode — HP Fault in memory Cycling Code 2

Flashing Code 3 Test Mode — LP Fault in memory Cycling Code 3

Flashing Code 4 Test Mode— FP1 Fault in memory CyclingCode 4

Flashing Code 5 Test Mode— FP2 Fault in memory CyclingCode 5

Flashing Code 6 Test Mode — CO Fault in memory Cycling Code 6

Flashing Code 7

Test Mode — Over/Under

shutdown in memory

Cycling Code 7

Flashing Code 8 Test Mode— PM inmemory Cycling Code 8

Flashing Code 9

Test Mode — FP1/FP2

Swapped Fault in memory

Cycling Code 9

CO — Condensate Overflow

FP — Freeze Protection

HP — High Pressure

LED — Light-Emitting Diode

LP — Low Pressure

PM — Performance Monitor

LED

CODE

FAULT DESCRIPTION

1 No fault in memory There has been no fault since

the last power-down to power-up

sequence

2 High-Pressure Switch HP Open Instantly

3 Low-Pressure Switch LP open for 30 continuous sec-

onds before or during a call

(bypassed for first 60 seconds)

4 Freeze Protection Coax

—FP1

FP1 below Temp limit for 30 con-

tinuous seconds (bypassed for

first 60 seconds of operation)

5 Freeze Protection Air Coil

—FP2

FP2 below Temp limit for 30 con-

tinuous seconds (bypassed for

first 60 seconds of operation)

6 Condensate overflow Sense overflow (grounded) for

30 continuous seconds

7

(Autoreset)

Over/Under Voltage

Shutdown

"R" power supply is <19VAC or

>30VAC

8 PM Warning PerformanceMonitorWarning

has occurred.

9 FP1 and FP2 Thermistors

are swapped

FP1 temperature is higher than

FP2 inheating/test mode,orFP2

temperature is higher thanFP1

in cooling/test mode.

FP — Freeze Protection

HP — High Pressure

LED — Light-Emitting Diode

LP — Low Pressure

PM — Performance Monitor