20

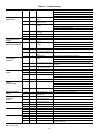

Table 9 — Typical Unit Operating Pressures and Temperatures

LEGEND NOTES:

1. Based on nominal 54 L/s per kW airflow and 21° C EATheating and 26.7/

194° C EAT cooling.

2. Coolingair and water numbers can vary greatly withchanges inhumidity.

3. Subcooling is based upon the head pressure at compressor service port.

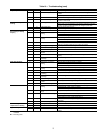

Table 10 — 50RHE Coaxial Water Pressure Drop

Flushing — Once the piping is complete, units require final

purging and loop charging. A flush cart pump of at least 1.5 hp

(1.12 kW) is needed to achieve adequate flow velocity in

the loop to purge air and dirt particles from the loop. Flush the

loop in both directions with a high volume of water at a high

velocity. Follow the steps below to properly flush the loop:

1. Verify power is off.

2. Fill loop with water from hose through flush cart before

using flush cart pump to ensure an even fill. Do not allow

the water level in the flush cart tank to drop below the

pump inlet line to prevent air from filling the line.

3. Maintain a fluid level in the tank above the return tee to

avoid air entering back into the fluid.

4. Shutting off the return valve that connects into the flush

cart reservoir will allow 345 kPa surges to help purge air

pockets. This maintains the pump at 345 kPa.

5. To purge, keep the pump at 345 kPa until maximum

pumping pressure is reached.

6. Open the return valve to send a pressure surge through

the loop to purge any air pockets in the piping system.

7. A noticeable drop in fluid level will be seen in the flush

cart tank. This is the only indication of air in the loop.

NOTE: If air is purged from the system while using a 254 mm

PVC flush tank, the level drop will only be 25 to 51 mm since

liquids are incompressible. If the level drops more than this,

flushing should continue since air is still being compressed in

the loop. If level is less than 25 to 51 mm, reverse the flow.

8. Repeat this procedure until all air is purged.

9. Restore power.

Antifreeze may be added before, during or after the flushing

process. However, depending on when it is added in the

process, it can be wasted. Refer to the Antifreeze section for

more detail.

Loop static pressure will fluctuate with the seasons. Pres-

sures will be higher in the winter months than during the warm-

er months. This fluctuation is normal and should be considered

when charging the system initially. Run the unit in either heat-

ing or cooling for several minutes to condition the loop to a

homogenous temperature.

When complete, perform a final flush and pressurize the

loop to a static pressure of 275 to 345 kPa for winter months or

105 to 135 kPa for summer months.

After pressurization, be sure to remove the plug from the

end of the loop pump motor(s) to allow trapped air to be

discharged and to ensure the motor housing has been flooded.

Be sure the loop flow center provides adequate flow through

the unit by checking pressure drop across the heat exchanger.

Compare the results to the data in Table 10.

ENTERING

WATER

TEMP (C)

(EWT)

WATER

FLOW

(l/s per kW)

COOLING HEATING

Suction

Pressure

(kPa)

Discharge

Pressure

(kPa)

Super-

heat

(C)

Sub-

cooling

(C)

Water Temp

Rise

(C)

Air Temp

Drop (C)

DB

Suction

Pressure

(kPa)

Discharge

Pressure

(kPa)

Super-

heat

(C)

Sub-

cooling

(C)

Water Temp

Drop (C) DB

Air

Temp

Rise (C)

–1

0.027 225-254 269-314 14-22 7-11 12-13 12-14 102-117 499-556 7- 9 1-2 4-5 8-11

0.041 222-251 239-284 14-22 6-10 7- 9 12-14 111-129 514-571 7- 9 1-2 3-4 9-12

0.054 219-248 209-254 14-22 6- 9 3- 6 12-14 120-138 529-586 7- 9 1-2 2-3 9-12

10

0.027 225-254 374-463 7-11 6-10 11-13 11-14 150-179 538-628 6- 9 1-3 6-7 13-16

0.041 222-251 359-425 7-11 5- 9 7- 8 11-14 158-185 553-643 6- 9 1-3 4-5 13-17

0.054 219-248 344-413 7-11 4- 8 4- 7 11-14 164-194 568-658 6- 9 1-3 3-4 14-17

21

0.027 225-254 535-592 5- 9 4- 8 11-12 11-13 212-245 613-688 8-11 1-3 8-9 16-19

0.041 222-251 502-556 5- 9 4- 7 7- 9 11-13 218-254 628-712 8-11 1-3 5-6 17-21

0.054 219-248 472-523 5- 9 4- 7 4- 7 11-13 227-263 643-724 8-11 1-3 3-4 17-21

32

0.027 225-254 685-750 5- 9 4- 8 10-12 9-13 254-284 658-777 10-16 1-3 8-9 18-22

0.041 222-251 652-721 5- 9 4- 7 6- 8 9-13 269-299 673-792 10-16 1-3 6-7 18-23

0.054 219-248 622-688 5- 9 4- 7 3- 6 9-13 284-314 688-807 10-16 1-3 4-5 19-23

43

0.027 231-260 837-957 4- 8 6-14 9-11 8-11

0.041 228-257 807-927 4- 8 6-13 5- 7 8-11

0.054 225-254 777-897 4- 8 6-12 3- 6 8-11

DB — Dry Bulb

EAT — Entering Air Temperature

UNIT

50RHE

L/S

PRESSURE DROP (kPa)

0° C 10° C 20° C 30° C

006

0.047 6.0 5.4 5.1 4.8

0.071 8.4 7.8 7.2 6.9

0.095 14.1 13.2 12.0 11.7

009

0.071 8.1 7.5 6.9 6.6

0.107 12.0 11.1 10.5 9.9

0.139 23.9 22.4 20.9 20.0

012

0.095 19.1 17.9 16.7 16.1

0.145 41.3 38.9 36.2 34.7

0.189 66.1 61.9 57.7 55.0

015

0.114 16.7 15.5 14.7 14.1

0.164 32.6 30.5 28.7 27.2

0.221 55.9 52.3 48.7 46.3

019

0.142 12.9 12.0 11.1 10.8

0.215 23.0 21.5 20.3 19.1

0.284 45.4 42.5 39.8 37.7

024

0.189 13.8 12.6 11.7 11.4

0.284 28.7 26.9 25.1 23.9

0.379 47.8 44.9 41.9 39.8

030

0.237 9.9 9.0 8.4 8.1

0.347 17.0 15.8 14.7 14.1

0.473 26.9 25.4 23.6 22.4

036

0.284 7.8 7.2 6.9 6.6

0.426 15.0 13.8 12.9 12.3

0.568 23.9 22.4 20.9 20.0

042

0.331 9.9 9.3 8.7 8.4

0.498 19.7 18.5 17.0 16.4

0.663 31.1 29.3 27.5 26.0

048

0.379 14.1 13.2 12.3 11.7

0.568 26.9 25.4 23.6 22.4

0.757 44.0 41.0 38.3 36.5

060

0.473 33.5 31.4 29.3 27.8

0.713 58.3 54.4 50.8 48.4

0.947 88.5 82.8 77.1 73.3