19

Scroll Compressor Rotation — It is important to be

certain compressor is rotating in the proper direction. To

determine whether or not compressor is rotating in the proper

direction:

1. Connect service gages to suction and discharge pressure

fittings.

2. Energize the compressor.

3. The suction pressure should drop and the discharge

pressure should rise, as is normal on any start-up.

If the suction pressure does not drop and the discharge

pressure does not rise to normal levels:

1. Turn off power to the unit. Install disconnect tag.

2. Reverse any two of the unit power leads.

3. Reapply power to the unit and verify pressures are correct.

The suction and discharge pressure levels should now move

to their normal start-up levels.

When the compressor is rotating in the wrong direction, the

unit makes more noise and does not provide cooling.

After a few minutes of reverse operation, the scroll com-

pressor internal overload protection will open, thus activating

the unit lockout. This requires a manual reset. To reset, turn the

thermostat on and then off.

NOTE: There is a 5-minute time delay before the compressor

will start.

Unit Start-Up Cooling Mode

1. Adjust the unit thermostat to the warmest position.

Slowly reduce the thermostat position until the compres-

sor activates.

2. Check for cool air delivery at unit grille a few minutes

after the unit has begun to operate.

3. Verify that the compressor is on and that the water flow

rate is correct by measuring pressure drop through the

heat exchanger using P/T plugs. See Table 8. Check the

elevation and cleanliness of the condensate lines; any

dripping could be a sign of a blocked line. Be sure the

condensate trap includes a water seal.

4. Check the temperature of both supply and discharge wa-

ter. Compare to Table 9. If temperature is within range,

proceed. If temperature is outside the range, check the

cooling refrigerant pressures in Table 9.

5. Check air temperature drop across the coil when com-

pressor is operating. Air temperature drop should be

between 8.3 and 13.9.

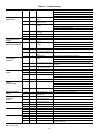

Table 8 — Water Temperature Change

Through Heat Exchanger

Unit Start-Up Heating Mode

NOTE: Operate the unit in heating cycle after checking the

cooling cycle. Allow five minutes between tests for the pres-

sure or reversing valve to equalize.

1. Turn thermostat to lowest setting and set thermostat

switch to HEAT position.

2. Slowly turn the thermostat to a higher temperature until

the compressor activates.

3. Check for warm air delivery at the unit grille within a few

minutes after the unit has begun to operate.

4. Check the temperature of both supply and discharge

water. Compare to Table 9. If temperature is within range,

proceed. If temperature is outside the range, check the

heating refrigerant pressures in Table 9.

5. Once the unit has begun to run, check for warm air deliv-

ery at the unit grille.

6. Check air temperature rise across the coil when compres-

sor is operating. Air temperature rise should be between

11.1 and 16.7 C after 15 minutes at load.

7. Check for vibration, noise and water leaks.

Flow Regulation — Flow regulation can be accom-

plished by two methods. Most water control valves have a flow

adjustment built into the valve. By measuring the pressure drop

through the unit heat exchanger, the flow rate can be deter-

mined. See Table 10. Adjust the water control valve until the

flow of .027 to .054 L/s per kW cooling is achieved. Since the

pressure constantly varies, two pressure gages may be needed

in some applications.

An alternative method is to install a flow control device.

These devices are typically an orifice of plastic material

designed to allow a specified flow rate that are mounted on the

outlet of the water control valve. Occasionally these valves

produce a velocity noise that can be reduced by applying some

back pressure. To accomplish this, slightly close the leaving

isolation valve of the well water setup.

WATER FLOW RATE (l/s)

COOLING

RISE (C)

HEATING

DROP (C)

Min Max Min Max

For Closed Loop: Ground

Source or Cooling/Boiler

Systems at 0.054 l/s per kW

5 6.7 2.2 4.4

For Open Loop: Ground

Water Systems 0.027 l/s per kW

11.1 14.4 5.6 9.4

To avoid possible injury or death due to electrical shock,

open the power supply disconnect switch and secure it in

an open position before flushing system.