18

Factory--Option Thru--Base Connections —

Electrical Connections: Knockouts are located in the

control box area. Remove the appropriate size knockout

for high voltage connection. Use the field supplied

connector depending on wiring or conduit being utilized.

Remove the

7

/

8

--in (22mm) knockout and appropriate

connector for low voltage wiring. If non--unit powered

convenience outlet is being utilized, remove the

7

/

8

-- i n

(22mm) knockout and utilize appropriate connector for

115 volt line. See “Step 12 — Making Electrical

Connections” for details.

Gas Connections: Remove the knockout in the base pan

and route

3

/

4

--in. gas line up through the opening. Install

an elbow and route gas line through opening in panel after

first removing plastic bushing. Install a gas shut off

followed by a drip leg and ground--joint union. Route gas

line into gas section through the grommet (Part #:

KA56SL112) at the gas inlet and into the gas valve. See

Fig. 17 and Table 2. If a regulator is installed, it must be

located 4 feet (1.22 meters) from the flue outlet.

Some municipal codes require that the manual shutoff

valve be located upstream of the sediment trap. See

Fig. 18 for typical piping arrangements for gas piping that

has been routed through the sidewall of the base pan.

When installing the gas supply line, observe local codes

pertaining to gas pipe installations. Refer to the NFPA

54/ANSI Z223.1 NFGC latest edition (in Canada, CAN/CSA

B149.1). In the absence of local building codes, adhere to

the following pertinent recommendations:

1. Avoid low spots in long runs of pipe. Grade all pipe

1

/

4

--in. in every 15 ft (7 mm in every 5 m) to prevent

traps. Grade all horizontal runs downward to risers.

Use risers to connect to heating section and to meter.

2. Protect all segments of piping system against physical

and thermal damage. Support all piping with appro-

priate straps, hangers, etc. Use a minimum of one

hanger every 6 ft (1.8 m). For pipe sizes larger than

1

/

2

--in., follow recommendations of national codes.

3. Apply joint compound (pipe dope) sparingly and only to

male threads of joint when making pipe connections.

Use only pipe dope that is resistant to action of lique-

fied petroleum gases as specified by local and/or nation-

al codes. If using PTFE (Teflon) tape, ensure the materi-

al is Double Density type and is labeled for use on gas

lines. Apply tape per manufacturer’s instructions.

4. Pressure--test all gas piping in accordance with local

and national plumbing and gas codes before connect-

ing piping to unit.

NOTE: Pressure test the gas supply system after the gas

supply piping is connected to the gas valve. The supply

piping must be disconnected from the gas valve during the

testing of the piping systems when test pressure is in

excess of 0.5 psig (3450 Pa). Pressure test the gas supply

piping system at pressures equal to or less than 0.5 psig

(3450 Pa). The unit heating section must be isolated from

the gas piping system by closing the external main manual

shutoff valve and slightly opening the ground--joint union.

Check for gas leaks at the field--installed and

factory--installed gas lines after all piping connections have

been completed. Use soap--and--water solution (or method

specified by local codes and/or regulations).

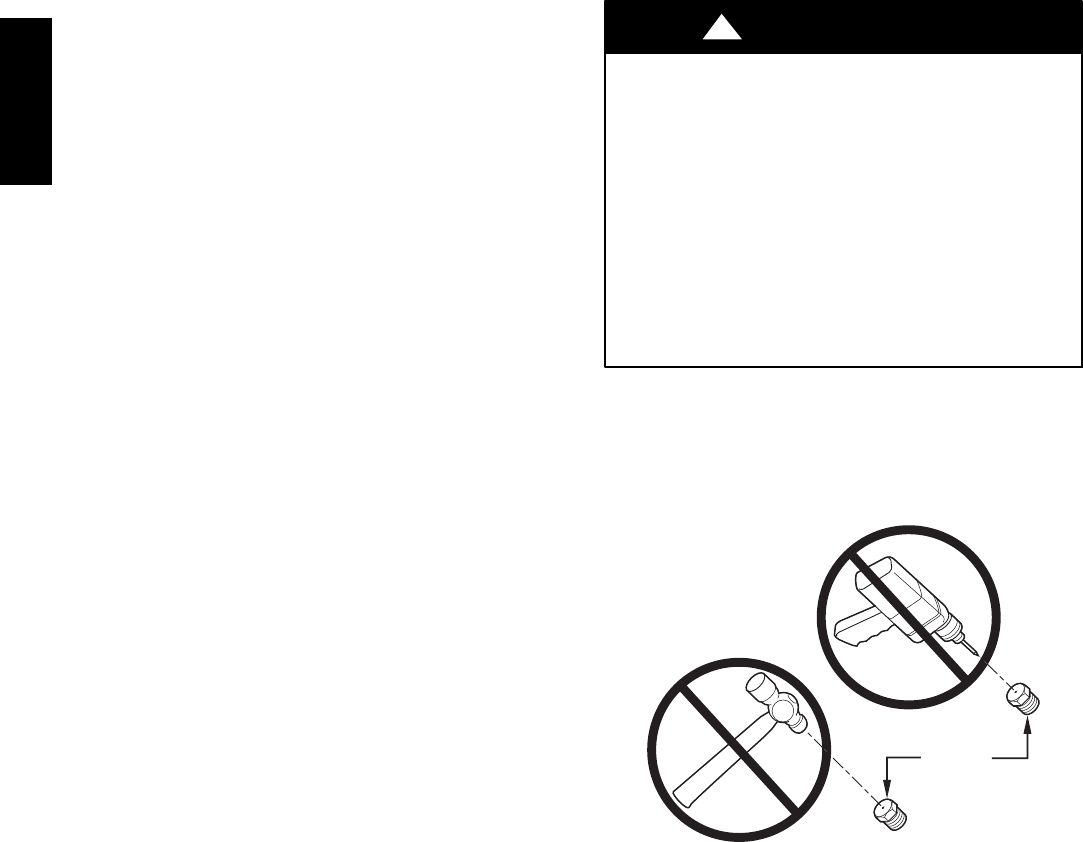

FIRE OR EXPLOSION HAZARD

Failure to follow this warning could result in personal

injury, death and/or property damage.

S Connect gas pipe to unit using a backup wrench to

avoid damaging gas controls.

S Never purge a gas line into a combustion chamber.

S Never test for gas leaks with an open flame. Use a

commercially available soap solution made

specifically for the detection of leaks to check all

connections.

S Use proper length of pipe to avoid stress on gas

control manifold.

!

WARNING

NOTE: If orifice hole appears damaged or it is suspected to

have been redrilled, check orifice hole with a numbered drill

bit of correct size. Never redrill an orifice. A burr--free and

squarely aligned orifice hole is essential for proper flame

characteristics.

BURNER

ORIFICE

A93059

Fig. 20 -- Orifice Hole

48HC