9

Table 5 — Refrigerant Specialties Part Numbers.

INSTALL LIQUID LINE SOLENOID VALVE —

It is recommended that a bi-directional solenoid valve be

placed in the main liquid line (see Figs. 5 & 6) between the

outdoor unit and the indoor coil. Locate the solenoid valve at

the end of the liquid line, near the outdoor unit connections,

with flow direction arrow pointed at the outdoor unit. Refer to

Table 5. (A liquid line solenoid valve is required when the

liquid line length exceeds 75 ft [23 m].) This valve prevents

refrigerant migration (which causes oil dilution) to the

compressor during the off cycle, at low outdoor ambient

temperatures. Wire the solenoid according to the unit label

diagram.

CAPACITY CONTROL LIQUID LINE SOLENOID VALVE

Evaporator capacity control via liquid solenoid valve is not rec-

ommended for use with 38AUQ models.

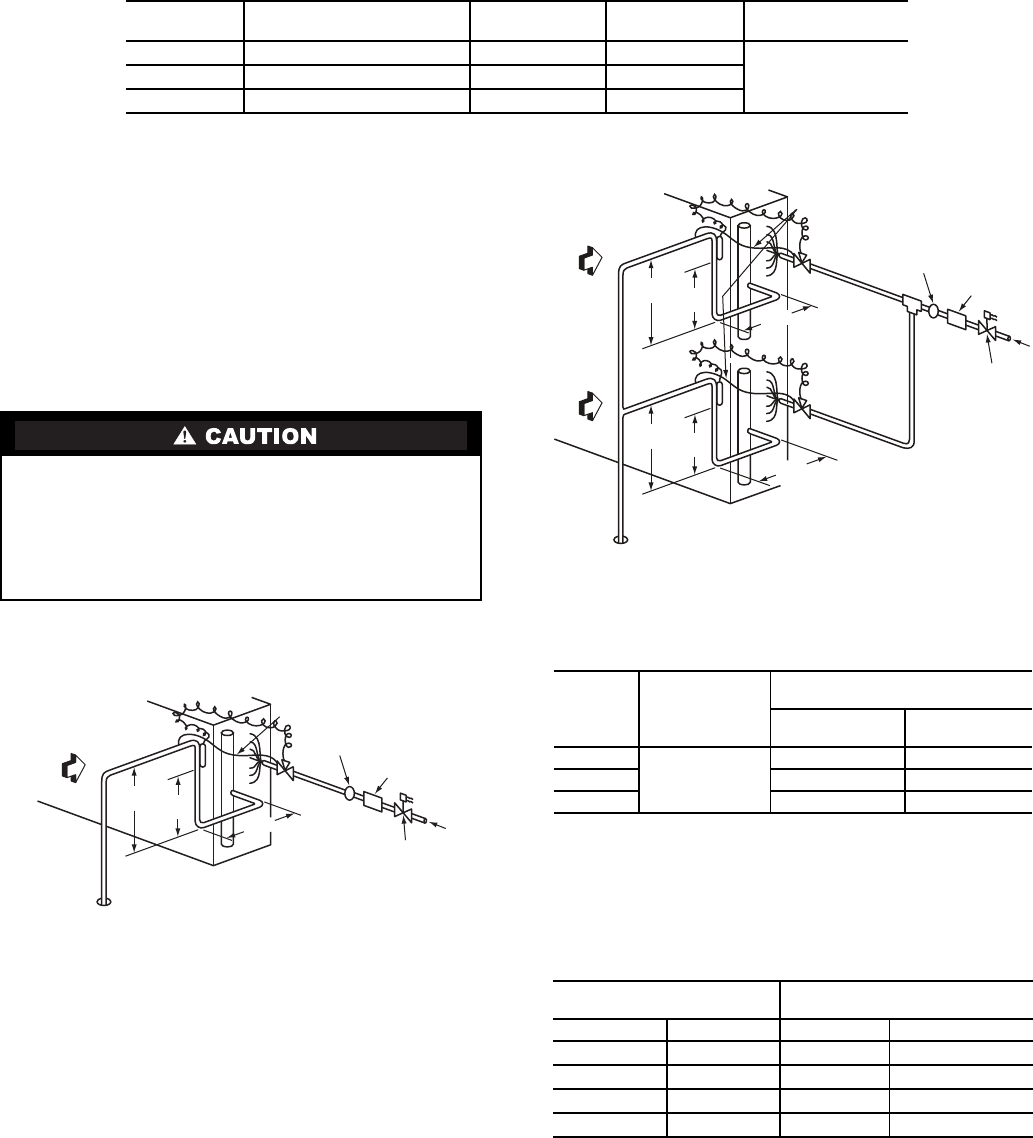

Fig.5 — Location of Sight Glass(es) and Filter Driers

(typical 38AUQ/40RUQ size 07 & 08 systems)

Fig.6 — Location of Sight Glass(es) and Filter Driers

(typical 38AUQ/40RUQ size 12 system)

Table 6 — Minimum Outdoor Air Operating Temperature

*Applies to Cooling mode of operation only.

†Wind baffles (field-supplied and field-installed) are recommended

for all units with low ambient head pressure control. Refer to Low

Ambient Control Installation Instructions (shipped with accessory)

for details.

Table 7 — Insulation for Vapor Line Exposed

to Outdoor Conditions

*Recommended vapor line insulation for piping exposed to outdoor

conditions to prevent loss of heating during heating cycle. When

vapor line goes through interior spaces, insulation should be

selected to prevent condensation on cooling cycle. Heating capac-

ity should be reduced 1000 Btuh (295 W) if over 35 ft (11 m) of

vapor line with

3

/

4

in. (19 mm) insulation is exposed to outdoor con-

ditions.

†Closed cell foam insulation with a thermal conductivity of: 0.28 Btu

• in./ft

2

• h • °F (0.04 W/m • °C).

LIQUID LINE

SIZE (in.)

LIQUID LINE

SOLENOID VALVE (LLSV)

LLSV

COIL

SIGHT

GLASS

FILTER

DRIER

3

/

8

ALC-066208 AMG-24/50-60 HMI-1TT3

Provided with unit

See Table 4

1

/

2

ALC-066209

†

AMG-24/50-60 HMI-1TT4

5

/

8

ALC-066212 AMG-24/50-60 HMI-1TT5

†

38AUD units require TWO sets of parts.

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage.

Failure to use a solenoid valve relay (SUR) accessory may

cause overload of Comfort Alert Diagnostic Module

(CADM) and compressor alarm lock out.

15 DIAMS

MIN

10

DIAMS

8 DIAMS

MIN

INDOOR

COIL CKT

AIRFLOW

TXV

SENSING

BULB

EQUALIZER LINE

SIGHT GLASS

A LOCATION

TXV

FILTER DRIER

A LOCATION

LIQUID

LINE

SOLENOID

VALVE

FLOW

LEGEND

TXV — Thermostatic Expansion Valve

UNIT

%

COMPRESSOR

CAPACITY

MINIMUM OUTDOOR

TEMP — F (C)*

Standard Unit

Head Pressure

Control†

38AUQ07

100

35 (1.7) –20 (–28.9)

38AUQ08 35 (1.7) –20 (–28.9)

38AUQ12 35 (1.7) –20 (–28.9)

LENGTH OF EXPOSED

VAPOR LINE*

INSULATION THICKNESS†

ft m in. mm

10 3

3

/

8

10

25 8

1

/

2

13

35 11

3

/

4

19

50 15

3

/

4

19

LEGEND

TXV — Thermostatic Expansion Valve

INDOOR

COIL CKT 2

AIRFLOW

INDOOR

COIL CKT 1

AIRFLOW

15 DIAMS

MIN

10

DIAMS

8 DIAMS

MIN

TXV

SENSING

BULB

EQUALIZER LINE

SIGHT GLASS

LOCATION

TXV

CKT 2

FILTER DRIER

LOCATION

LIQUID

LINE

SOLENOID

VALVE

FLOW

TXV

SENSING

BULB

TXV

CKT 1

8 DIAMS

MIN

15 DIAMS

MIN

10

DIAMS