30

Table 15 — CADM Troubleshooting

Lubrication

FAN MOTORS have sealed bearings. No provisions are made

for lubrication.

COMPRESSOR has its own oil supply. Loss of oil due to a

leak in the system should be the only reason for adding oil after

the system has been in operation.

Outdoor Coil Maintenance and Cleaning

Recommendation

Routine cleaning of coil surfaces is essential to maintain proper

operation of the unit. Elimination of contamination and remov-

al of harmful residues will greatly increase the life of the coil

and extend the life of the unit. The following maintenance and

cleaning procedures are recommended as part of the routine

maintenance activities to extend the life of the coil.

Remove Surface Loaded Fibers

Surface loaded fibers or dirt should be removed with a vacuum

cleaner. If a vacuum cleaner is not available, a soft non-metallic

bristle brush may be used. In either case, the tool should be

applied in the direction of the fins. Coil surfaces can be easily

damaged (fin edges can be easily bent over and damage the

coating of a protected coil) if the tool is applied across the fins.

NOTE: Use of a water stream, such as a garden hose,

against a surface loaded coil will drive the fibers and dirt

into the coil. This will make cleaning efforts more difficult.

Surface loaded fibers must be completely removed prior to

using low velocity clean water rinse.

Periodic Clean Water Rinse

A periodic clean water rinse is very beneficial for coils that are

applied in coastal or industrial environments. However, it is

very important that the water rinse is made with very low ve-

locity water stream to avoid damaging the fin edges. Monthly

cleaning as described below is recommended.

Routine Cleaning of Indoor Coil Surfaces

Periodic cleaning with Totaline

®

environmentally sound coil

cleaner is essential to extend the life of coils. This cleaner is

available from Carrier Replacement Components Division as

part number P902-0301 for one gallon container, and part num-

ber P902-0305 for a 5 gallon container. It is recommended that

all coils, including standard aluminum, pre-coated, copper/cop-

per or E-coated coils be cleaned with the Totaline environmen-

tally sound coil cleaner as described below. Coil cleaning

should be part of the unit's regularly scheduled maintenance

procedures to ensure long life of the coil. Failure to clean the

coils may result in reduced durability in the environment.

Avoid the use of

• coil brighteners

• acid cleaning prior to painting

• high pressure washers

• poor quality water for cleaning

Totaline environmentally sound coil cleaner is nonflammable,

hypoallergenic, non bacterial, and a USDA accepted biode-

gradable agent that will not harm the coil or surrounding com-

ponents such as electrical wiring, painted metal surfaces, or in-

sulation. Use of non-recommended coil cleaners is strongly

discouraged since coil and unit durability could be affected.

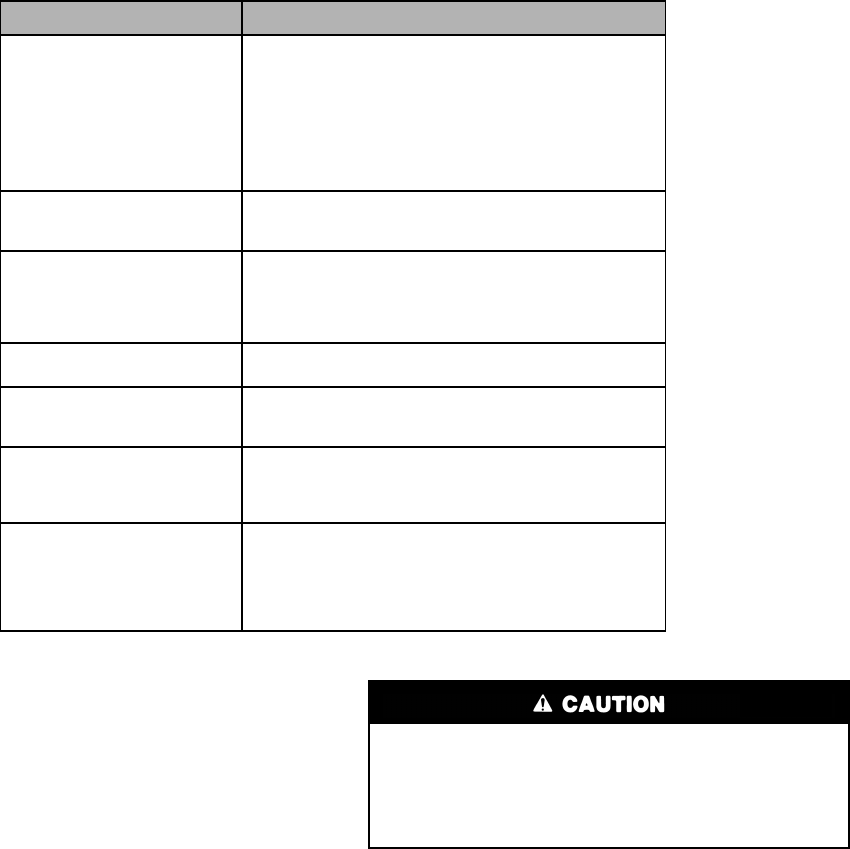

Miswired Module Indication Recommended Troubleshooting Action

Green LED is not on,

module does not power up

Determine if both R and C module terminals are

connected. Verify voltage in present at module’s R and C

terminals.

NOTE: The CADM requires a constant nominal 24VAC

power supply. The wiring to the module’s R and C

terminals must be directly from the control transformer.

The module cannot receive its power from another device

that will interrupt the 24VAC power supply. See Fig. 19,

the 38AUQ Wiring Diagram.

Green LED Intermittent,

module powers up only

when compressor runs

Determine if R and Y terminals are wired in reverse. Verify

module’s R and C terminals have a constant source. See

“NOTE” above for details on R and C wiring.

TRIP LED is on but system

and compressor check OK

Verify Y terminal is wired properly per the 38AUQ wiring

diagram (see Fig. 19). Verify voltage at contactor coil falls

below 0.5VAC when off. Verify 24VAQC is present across

Y and C when thermostat demand signal is present. If not,

R and C are reverse wired.

TRIP LED and ALERT LED

flashing together

Verify R and C terminals are supplied with 19-28VAC.

ALERT Flash Code 3

(Compressor Short Cycling)

displayed incorrectly

Verify Y terminal is connected to 24VAC at contactor coil.

Verify voltage at contactor coil falls below 0.5VAC when

off.

ALERT Flash Code 5 or 6

(Open Circuit, Missing Phase)

displayed incorrectly

Check that compressor T1 and T3 wires are through

module’s current sensing holes. Verify Y terminal is

connected to 24VAC at contactor coil. Verify voltage at

contactor coil falls below 0.5VAC when off.

Alert Flash Code *

(Welded Contactor)

displayed incorrectly

Determine if module’s Y terminal is connected. Verify Y

terminal is connected to 24VAC at contactor coil. Verify

24VAC is present across Y and C when thermostat

demand signal is present. If not, R and C are reverse

wired. Verify voltage at contactor coil falls below 0.5VAC

when off.

PERSONAL INJURY AND UNIT DAMAGE

HAZARD

Failure to follow this caution may result in personal injury

or equipment damage.

Only approved cleaning is recommended.