Order No. 13444-76, 06.2005. Supersedes order No.: 13429-76, 06.2004. Manufactured by: Carrier s.a., Montluel, France.

Manufacturer reserves the right to change any product specification without notice. Printed in the Netherlands on chlorine-free paper.

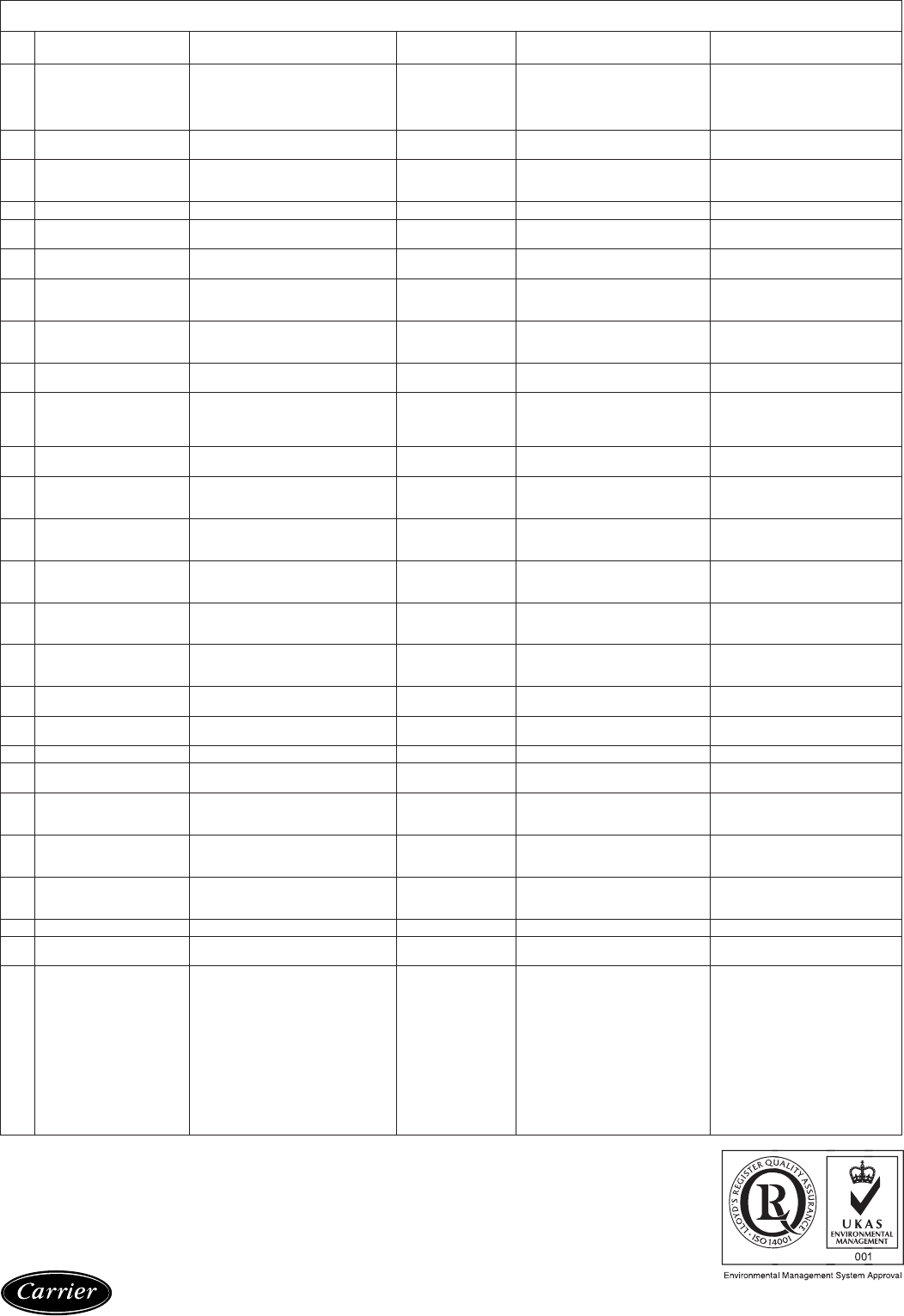

A

LARM

C

ODE

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55-2

55-4

55-5

55-6

ALARM NAME

Low refrigerant pressure failure,

circuit A

Low refrigerant pressure failure,

circuit B

High pressure failure, circuit A

High pressure failure, circuit B

Reverse compressor rotation,

circuit A

Reverse compressor rotation,

circuit B

Water heat exchanger frost

protection

Repeated low evaporator

suction temperature unloading,

circuit A

Repeated low evaporator suction

temperature unloading, circuit B

Repeated high pressure

unloading, circuit A

Repeated high pressure

unloading, circuit B

Repeated high discharge

temperature unloading in

heating mode, circuit A

Repeated high discharge

temperature unloading in

heating mode, circuit B

Repeated low suction

temperature unloading in

heating mode, circuit A

Repeated low suction

temperature unloading in

heating mode, circuit B

Low heat exchanger entering

water temperature in heating

mode

Safety interlock open

Pump #1 fault

Pump #2 fault

CCN emergency stop

Loss of communication with

System Manager

Communication failure with the

master or the slave unit

Initial factory configuration

required

Illegal factory configuration

Master/slave configuration error

Maintenance alerts

Water loop flow rate too low

Maintenance delay, pump 1,

elapsed

Maintenance delay, pump 2,

elapsed

Maintenance delay, water filter,

elapsed

ALARM DESCRIPTION

Circuit running and the suction pressure

below threshold

As above

Circuit running and the discharge pressure

exceeds the high pressure trip point

As above

One circuit compressor runs in reverse

rotation

As above

The heat exchanger entering or leaving

water sensor is below the frost trip point

More than 6 successive circuit capacity

unloads because of low suction temperature

override.

As above

More than 6 successive circuit capacity

unloads because of high pressure override.

As above

More than 8 successive circuit capacity

unloads because of high discharge

temperature

As above

More than 8 successive circuit capacity

unloads because of low suction temperature

As above

Heat exchanger temperature is too low (less

than 10°C), preventing unit start-up

Safety interlock not closed before end of the

start-up delay or opens during operation

Evap. water pump run contact opens while

the pump has received a command to be on

As above

CCN command received to shutdown the

unit

The unit is controlled by a System Manager

and communication with this module is lost

for more than 2 minutes

The master/slave link is broken due to a

loss of communication between the two

units for more than 2 minutes

All factory parameters are zero

Wrong factory configuration

Wrong master/slave configuration

A maintenance alert is active

ACTION TAKEN BY

THE CONTROL

Circuit shut down

As above

Circuit shut down

As above

As above

As above

Unit shut down

Circuit shut down

As above

None

As above

As above

As above

As above

As above

Unit shut down

Unit prevented to start

or shut down

Unit shut down

Unit shut down

Unit shut down

Unit returns to

autonomous operating

mode

As above

Unit prevented to start

As above

Master/slave control

disabled

None

RESET TYPE

Automatic when pressure returns to

normal and if the same fault has not

occurred the same day (machine

equipped with CCN/clock board, If not,

manual)

As above

Manual, the high pressure switch must

be reset manually with the push-button

located on or in the pressure switch

As above

As above

As above

Automatic if the same alarm has not

tripped the same day (machine equipped

with CCN/clock board, If not, manual)

Manual

As above

Automatic

As above

As above

As above

As above

As above

As above

Manual

Manual

Manual

Manual

Automatic when communication is re-

established

As above

Automatic

Automatic

Automatic

Manual

PROBABLE CAUSE

Shortage of refrigerant, filter blocked or

faulty pressure sensor

As above

Fan circuit fault, high condenser

entering air temperature

As above

Incorrect compressor wiring

As above

Low water flow or defective thermistor

Faulty pressure sensor, clogged filter or

low refrigerant charge

As above

Faulty transducer, high condenser

entering air temperature, high entering

water temperature, condenser fouled

fan flow rate too low.

As above

Pressure sensor faulty or heat

exchanger fouled

As above

Pressure sensor faulty, filter obstructed,

shortage of refrigerant, heat exchanger

fouled or fan faulty.

As above

As above

Evaporator pump control or water flow

switch failure

Pump overheat, incorrect pump

connection

As above

Network command

Defective CCN bus wiring or system

module failure

As above

No factory configuration

Factory configuration error

Master or slave configuration error

ALARM CODE DESCRIPTIONS (continued)