29

5 - PRO-DIALOG CONTROL OPERATION

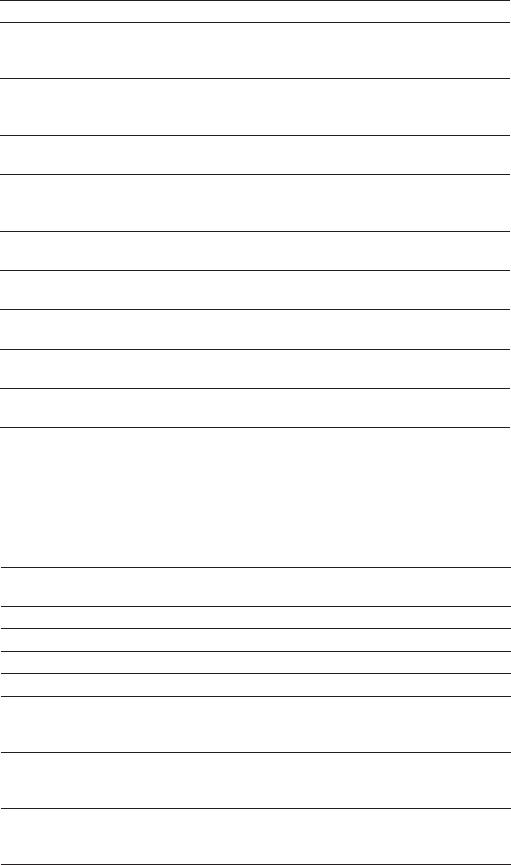

5.1 - Start/stop control

The table below summarises the unit control type and stop or

go status with regard to the following parameters.

- Operating type: this is selected using the start/stop button

on the front of the user interface.

- Remote start/stop contacts: these contacts are used when

the unit is in remote operating type (rEM). See sections

3.6.2 and 3.6.3.

- CHIL_S_S: this network command relates to the chiller

start/stop when the unit is in CCN control (CCn). Vari-

able forced to disable: the unit is halted. Variable forced to

Enable: the unit runs in accordance with schedule 1.

- Start/Stop schedule: occupied or unoccupied status of the

unit as determined by the chiller start/stop program

(Schedule #1). Used when the unit is equipped with an

optional CCN/clock board, otherwise the chiller occupied

mode is forced to occupied all the time.

- Master control type. This parameter is used when the

unit is the master unit in a two chiller lead/lag arrange-

ment. The master control type determines whether the unit

is to be controlled locally, remotely or through CCN (this

parameter is a Service configuration).

- CCN emergency shutdown: if this CCN command is

activated, it shuts the unit down whatever the active

operating type.

- General alarm: the unit is totally stopped due to failure.

ITEM #

0

1 [1]

2 [1]

3 [1]

4 [1]

5 [1]

6 [1]

7 [1]

FORMAT

MAintEnAnCE MEnu

ALErt

nnn/ALErt

nnn/ALErt

nnn/ALErt

DESCRIPTION

When selected this item authorises return to

the previous menu.

Accessible with the Service password.

For future use

For future use

Water loop rate to low

Next primary pump maintenance operation in

nnn days. 'ALErt' is displayed, when the delay

before maintenance has elapsed.

Next secondary pump maintenance operation

in nnn days. 'ALErt' is displayed, when the

delay before maintenance has elapsed.

Next water filter maintenance operation in nnn

days. 'ALErt' is displayed, when the delay

before maintenance has elapsed.

1 This item is masked when not used.

ITEM #

0

1

2

3

4

5 [1]

6 [1]

7 [1]

8 [1]

FORMAT

-

nn

nn

nn

nn

nnnn | M 10 | M100

nnnn | M 10

nnnn | M 10 | M100

nnnn | M 10 | M100

UNITS

-

-

-

minutes

minutes

hrs/10 or 100

hrs/10 or 100

-/10 or 100

-/10 or 100

DESCRIPTION

When selected this item

authorises return to the

previous menu

Compressor starts for

compressor with most starts

during the last hour

24 hours average number of

starts/hour, compressor

Minimum compressor

operating time during last

hour

24 hours average minimum

operating time above

Boiler operating hours

Electric heating stage

operating hours

No. of defrost cycles, circuit

A

No. of defrost cycles, circuit

B

4.3.14.2 - Description of Runtimes 2 menu

4.3.14.3 - Maintenance menu description

To be active, the maintenance function must be preset in the

Service configuration