35

A

LARM

C

ODE

1

2

3

5

6

7

9

10

11

12

13

14

15

16

17

18

21

22

23

24

ALARM NAME

Compressor A1 failure

Compressor A2 failure

Compressor A3 failure

Compressor B1 failure

Compressor B2 failure

Compressor B3 failure

Heat exchanger leaving fluid

thermistor failure

Heat exchanger entering fluid

thermistor failure

CHWS fluid thermistor failure

(master/slave)

Defrost sensor fault, circuit A

Defrost sensor fault, circuit B

OAT sensor failure

Discharge pressure transducer

failure, Circuit A

Discharge pressure transducer

failure, Circuit B

Suction pressure transducer

failure, Circuit A

Suction pressure transducer

failure, Circuit B

CCN/clock board failure

Loss of communication with

slave board

Loss of communication with

compressor slave board

Loss of communication with PD-

4 x DO slave board

ALARM DESCRIPTION

Motor safety input has opened due to

compressor overtemperature protection.

As above

As above

As above

As above

As above

Thermistor outside range

As above

As above

As above

As above

As above

Voltage delivered by the sensor is incorrect

Value read by the sensor is outside range

Voltage delivered by the sensor is incorrect

Value read by the sensor is outside range

The clock board is no longer detected

Communication has been lost with the slave

board (circuit B control)

Communication has been lost with the

compressor A3 + B3 control board

Communication has been lost with the

electric heating stage control board

ACTION TAKEN BY

THE CONTROL

Compressor is shut

down

As above

As above

As above

As above

As above

Unit shut down

As above

As above

Circuit shut down, if unit

is in heating mode

As above

As above

Circuit A shut down

Circuit B shut down

Circuit A shut down

Circuit B shut down

Unit shut down

Circuit B shut down

Compressors A3 + B3

shut down

Electric heating stages

shut down

RESET TYPE

Manual

As above

As above

As above

As above

As above

Automatic, if temp. measured by sensor

returns to permitted range of values

As above

As above

As above

As above

As above

Automatic if the voltage delivered by the

sensor returns to normal

As above

As above

As above

Automatic if board is detected again

Automatic if communication is re-

established

As above

As above

PROBABLE CAUSE

Compressor overheat

As above

As above

As above

As above

As above

Faulty thermistor, wiring error or

disconnection

As above

As above

As above

As above

As above

Defective transducer, wiring fault

As above

As above

As above

Defective CCN/clock board

Bus wiring fault, wrong software in slave

board or defective slave board

As above

As above

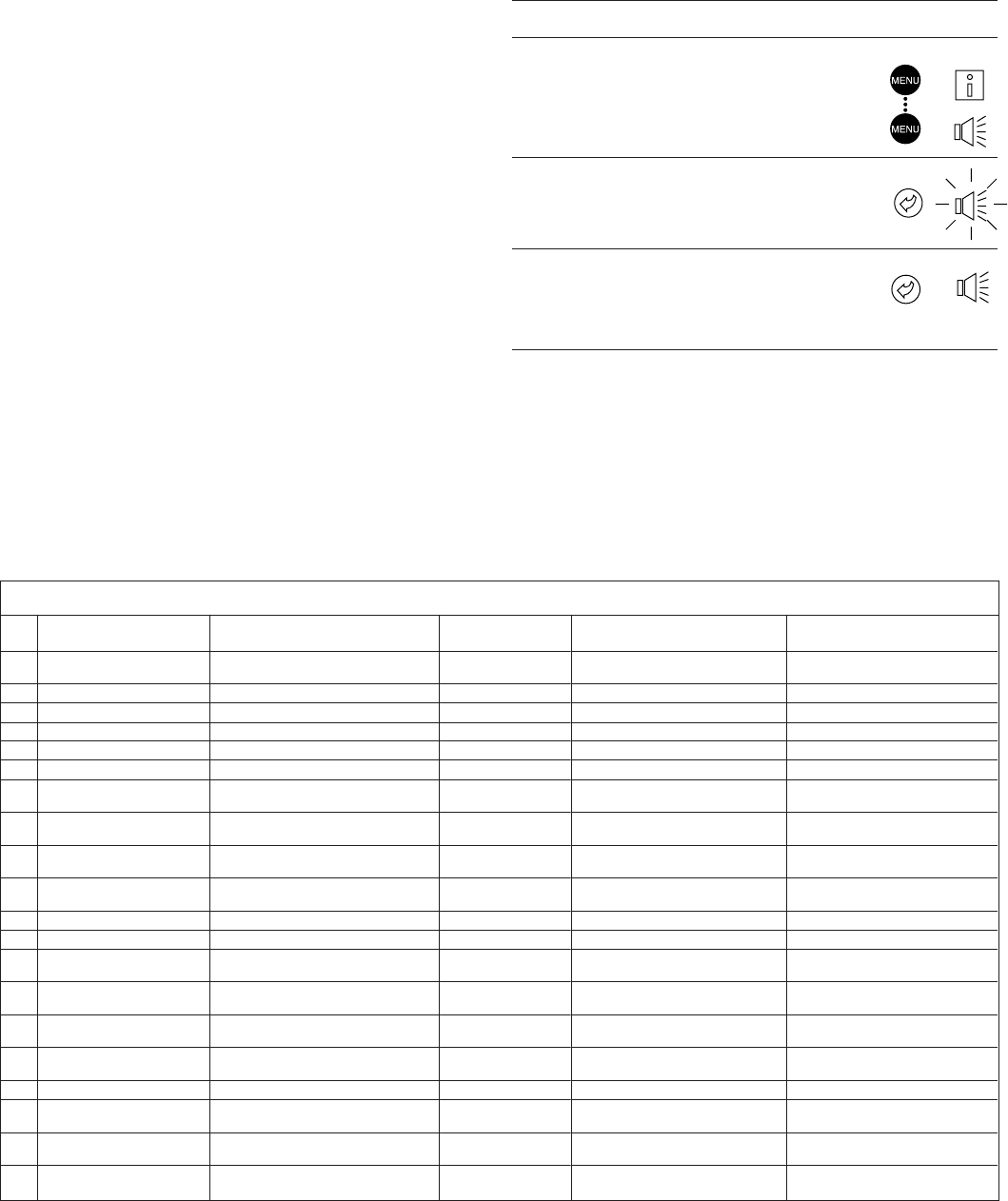

ALARM CODE DESCRIPTIONS

6 - DIAGNOSTICS - TROUBLESHOOTING

6.1 - General

The PRO-DIALOG control system has many fault tracing aid

functions. The local interface and its various menus give access

to all unit operating conditions. The test function makes it

possible to run a quick test of all devices on the unit. If an

operating fault is detected, an alarm is activated and an alarm

code is stored in the Alarm menu.

6.2 - Displaying alarms

The alarm LEDs on the summary interface (see section 4.1)

give a quick display of the status of each circuit and the unit as

a whole.

- A flashing LED shows that the circuit is operating but

there is an alarm.

- A steady LED shows that the circuit has been shut down

due to a fault.

The Alarm menu on the main interface displays up to 5 fault

codes that are active on the unit.

6.3 - Resetting alarms

When the cause of the alarm has been corrected the alarm can

be reset, depending on the type, either automatically on return

to normal, or manually when action has been taken on the unit.

Alarms can be reset even if the unit is running.

RESET OF ACTIVE ALARMS

OPERATION ITEM NUMBER ITEM VALUE PRESS MENU

2-DIGIT DISPLAY 4-DIGIT DISPLAY BUTTON LED

Hold down the MENU

button until the LED for

alarms lights. The 4-

digit display shows the

number of active

alarms (2 in this

example).

Press the Enter button

until "rESEt ALARrM" is

shown in the 4-digit

display.

Press the Enter button

again to validate the

reset. "Good" is

displayed for 2 seconds

then, "2 ALArM" and

then, "no ALArM".

0

0 2 ALArM

0 rESEt ALArM

0 Good

then, 2 AL

then, no ALArM

This means that an alarm can be reset without stopping the

machine. In the event of a power supply interrupt, the unit

restarts automatically without the need for an external com-

mand. However, any faults active when the supply is inter-

rupted are saved and may in certain cases prevent a circuit or a

unit from restarting.

A manual reset must be run from the main interface using the

following procedure:

6.4 - Alarm codes

The following list gives a complete description of each alarm code and its possible cause.