23

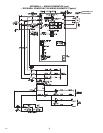

Servicing the Drive

1. Using recommended screwdriver = 6.4 mm (0.25 in.) flat

or T20 star, open access door. See Fig. 16.

2. Check to be sure that the voltage between DC+ and DC-

and from each DC terminal to the chassis is zero before

proceeding. See Fig. 17.

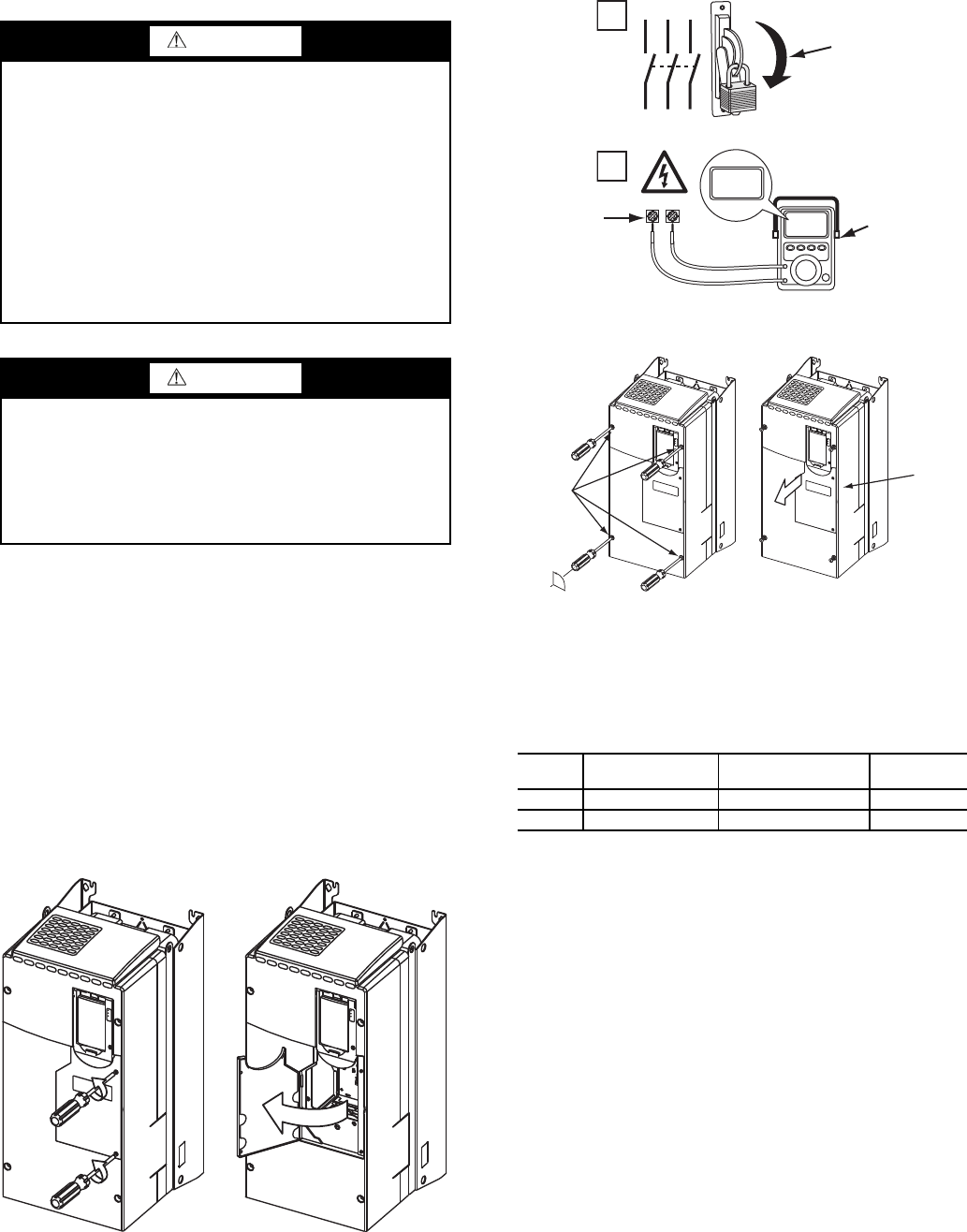

3. Remove the enclosure. See Fig. 18.

REMOVING THE DRIVE — The dimensions and weights

specified must be taken into consideration when removing the

drive. All lifting equipment and lifting components (hooks,

bolts, lifts, slings, chains, etc.) must be properly sized and rated

to safely lift and hold the weight of the drive while removing it.

See Fig. 19. The drive weights are as follows:

• Drive weight for Frame 6: 85 lb.

• Drive weight for Frame 7: 160 - 249 lb.

When replacing the drive, reverse the procedures and tight-

en to the torques for the Frames 6 and 7 Power Terminal Block

referred to in Table 8.

Table 8

— Frames 6 and 7 Power Terminal Block

RIGGING THE ENCLOSURE —

Where overhead room

and/or clearance in front of the drive enclosure is insufficient to

allow the drive to be safely removed from the enclosure, the

entire enclosure may have to be removed from the chiller.

The dimensions and weights specified must be taken into

consideration when removing the enclosure. The total weight

for Frames 6 and 7, including drive weight and enclosure, is

720 lb. All lifting equipment and lifting components (hooks,

bolts, lifts, slings, chains, etc.) must be properly sized and rated

to safely lift and hold the weight of the enclosure and drive

while removing. See Fig. 20A and Fig. 20B.

WARNING

To guard against possible personal injury and/or equipment

damage:

1. Inspect all lifting hardware for proper attachment be-

fore lifting drive.

2. Do not allow any part of the drive or lifting mecha-

nism to make contact with electrically charged con-

ductors or components.

3. Do not subject the drive to high rates of acceleration

or deceleration while transporting to the mounting lo-

cation or when lifting.

Do not allow personnel or their limbs directly underneath

the drive when it is being lifted and mounted.

WARNING

DC bus capacitors retain hazardous voltages after input

power has been disconnected. After disconnecting input

power, wait five (5) minutes for the DC bus capacitors to

discharge and then check the voltage with a voltmeter to

ensure the DC bus capacitors are discharged before touch-

ing any internal components. Failure to observe this pre-

caution could result in severe bodily injury or loss of life.

Fig. 16 — Open Access Door

A19-1831

FRAME

MAXIMUM LUG

WIDTH

RECOMMENDED

TORQUE

TERMINAL

BOLT SIZE

6 34.6 mm (1.36 in.) 11.3 N

·m (100 in.-lb) M8 x 1.25

7 43.5 mm (1.71 in.) 11.3 N

·m (100 in.-lb) M8 x 1.25

1

L1 L2 L3

O

I

2

DC+ DC–

0V

0V

LOCKOUT/TAGOUT

MULTIMETER

DC BUS TEST

TERMINALS

LOCATED INSIDE

ACCESS DOOR

Fig. 17 — Check DC Bus Terminals

A19-1814

90°

SLIDE

ENCLOSURE

FORWARD

LOOSEN

ENCLOSURE

FASTENERS

Fig. 18 — Removing Enclosure

A19-1816