9

Table 3

— Drive Status Indicator Descriptions

NOTES:

1. A Type 1 alarm indicates that a condition exists. Type 1 alarms

are user configurable.

2. A Type 2 alarm indicates that a configuration error exists and

the drive cannot be started. Type 2 alarms are not configurable.

VERIFYING THAT DC BUS CAPACITORS ARE DIS-

CHARGED — The drive’s DC bus capacitors retain hazard-

ous voltages after input power has been disconnected. Perform

the following steps before touching any internal components:

1. Turn off and lock out input power. Wait five minutes.

2. Verify that there is no voltage at the drive’s input power

terminals.

3. Measure the DC bus potential with a voltmeter while

standing on a non-conductive surface and wearing insu-

lated gloves (1000 V). Measure the DC bus potential. See

Fig. 5 for the 248-amp drive and Fig. 6 for the 361 and

477-amp drives. The voltage between DC+ and DC-, and

from each DC terminal to the chassis must be zero before

proceeding.

4. Once the drive has been serviced, reapply input power.

HIGH TEMPERATURE ALARMS — Coolant flow

through the cold plate is controlled by an orifice in the refriger-

ant line leaving the cold plate. The orifice looks like one of the

O-ring face seal connectors and in fact is used as one of the

connections on the coolant tubing. The difference is that the

passage through the fitting is 0.375 in. (9.5 mm). If the orifice

is present and condenser liquid flow is present, the liquid will

flash to cooler temperature at the orifice. This temperature dif-

ference is great enough to be easily felt.

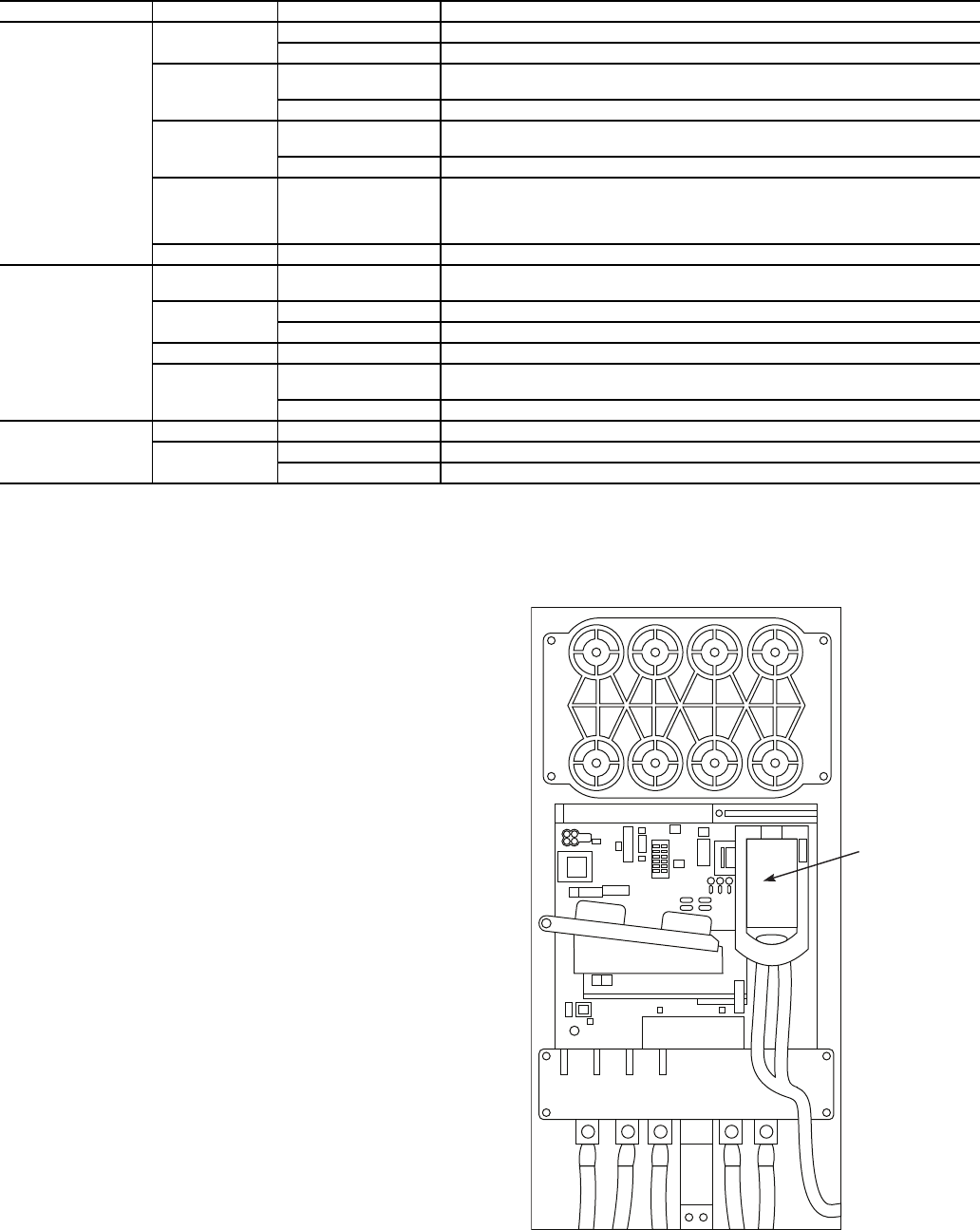

MAIN CONTROL BOARD (MCB) COMPONENTS —

Figure 13 shows the drive module with the cover removed. To

access the control boards, loosen the screw on the face of the

keypad mount and swing the keypad mount upward.

The components on the main control board (MCB) are

shown in Fig. 14. Note the location of the terminals labeled

MCB I/O. The high pressure switch is wired to these terminals

as shown in Fig. 15. In the event of a high condenser pressure

alarm, the connections at these terminals should be checked

and tightened if necessary.

A typical wiring schematic is shown in Appendix A.

NAME COLOR STATE DESCRIPTION

STS (Status)

Green Flashing Drive ready but not running, and no faults are present.

Steady Drive running, no faults are present.

Yellow Flashing Drive is not running. A type 2 (non-configurable) alarm condition exists and the

drive cannot be started.

Steady Drive is not running, a type 1 alarm condition exists. The drive can be started.

Red Flashing A major fault has occurred. Drive cannot be started until fault condition is

cleared.

Steady A non-resettable fault has occurred.

Red/Yellow Flashing Alternately A minor fault has occurred. When running, the drive continues to run. System is

brought to a stop under system control. Fault must be cleared to continue. Use

parameter 950 [Minor Flt Config] to enable. If not enabled, acts like a major

fault.

Green/Red Flashing Alternately Drive is flash updating.

ENET

None (Unlit) Off Adapter and/or network is not powered, adapter is not properly connected to

the network, or adapter needs an IP address.

Red Flashing An EtherNet/IP connection has timed out.

Steady Adapter failed the duplicate IP address detection test.

Red/Green Flashing Alternately Adapter is performing a self-test.

Green Flashing Adapter is properly connected but is not communicating with any devices on

the network.

Steady Adapter is properly connected and communicating on the network.

LINK

None (Unlit) Off Adapter is not powered or is not transmitting on the network.

Green Flashing Adapter is properly connected and transmitting data packets on the network.

Steady Adapter is properly connected but is not transmitting on the network.

SWING UP KEY PAD

MOUNT TO ACCESS

CONTROL BOARDS

Fig. 13 — Drive Module with Cover Removed

a19-1843