CLEANING AND

MAINTENANCE

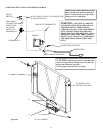

GLASS DOOR

Glass must be cleaned periodically. During

start-up it is normal for condensation to

form on the inside of the glass causing lint,

dust, and other airborne particles to cling

to the glass surface. During initial start-up

a slight film may form on the glass due to

paint curing. The glass should be cleaned

several times with a non-ammonia,

nonabrasive household cleaner and warm

water after the first two weeks of

operation. Thereafter, clean the glass two

or three times during each heating season,

depending on the usage and circumstances

present. Refer to Removing/Replacing

Glass Door on page 18 &19 of this manual

when removing glass door for cleaning.

WARNING: Turn off burner system

and let cool before cleaning.

CAUTION: You must keep control

areas, burners, and circulating air

passageways of burner system and

stove clean. Inspect these areas of

burner system and stove before each

use. Have burner system and stove

inspected yearly by a qualified service

person. Burner system and stove may

need more frequent cleaning due to

excessive lint from carpeting, bedding

material, pet hair, etc.

WARNING: Handle glass door panel

with care. Do not strike, slam, or

otherwise abuse glass. Do not operate

burner system with the glass door

removed, cracked, or broken.

Warning: Do not use abrasive

cleaners as this may damage glass.

Use a nonabrasive household glass

cleaner to clean glass. Do not clean

glass when hot.

WARNING: Only parts supplied by

the manufacturer should be used

when replacing broken or damaged

glass door panel (see Replacement

Parts, page 29). This glass door panel

is a complete unit. No substitute

materials may be used.

CAUTION: Wear gloves and safety

glasses while handling or removing

broken glass. Do not remove if glass is

hot. Keep children and pets away

from glass.

If glass has been broken, carefully

remove glass door (See Removing/

Replacing Glass Door, page 18 & 19).

Vacuum all glass pieces with a shop vac.

Use only the ceramic glass door

replacement intended for this burner

system (see Replacement Parts, page 29

for detail on ordering). No substitutions

may be made. See Removing/Replacing

Glass Door, page 18 & 19 for

instructions for replacing glass door.

PILOT AND BURNERS

Periodic visual check of pilot and

burner flames

• Burner and controls should be

cleaned with compressed air to

remove dust, dirt, or lint.

• Use a vacuum cleaner or small, soft

bristled brush to remove excess dust,

dirt, or lint.

WARNING: Do not operate burner

system with the glass door removed,

cracked, or broken.

LOGS

• If you remove logs for cleaning, refer

to Installing Logs, page 20 to

properly replace logs.

• Use a vacuum cleaner to remove any

carbon buildup on logs.

• Replace logs if broken. See

Replacement Parts on page 29.

VENTING SYSTEM

Periodic examination of venting

systems by a qualified agency.

1. Check areas of venting system that

are exposed to the weather for

corrosion (rust spots or streaks and,

in extreme cases, holes). Have these

items replaced immediately by a

qualified service person.

2. Remove the vent cap and shine a

flashlight into the vent. Remove any

foreign material.

3. Check for evidence of excessive

condensation. Continuous condensa-

tion can cause corrosion of caps,

pipes, and fittings and can be caused

by having excessive lateral runs, too

many elbows, or exterior portions of

the system being exposed to cold

weather.

4. Inspect joints to verify that no pipe

section or fitting has been disturbed

and loosened. Check mechanical

supports such as wall straps for

rigidity.

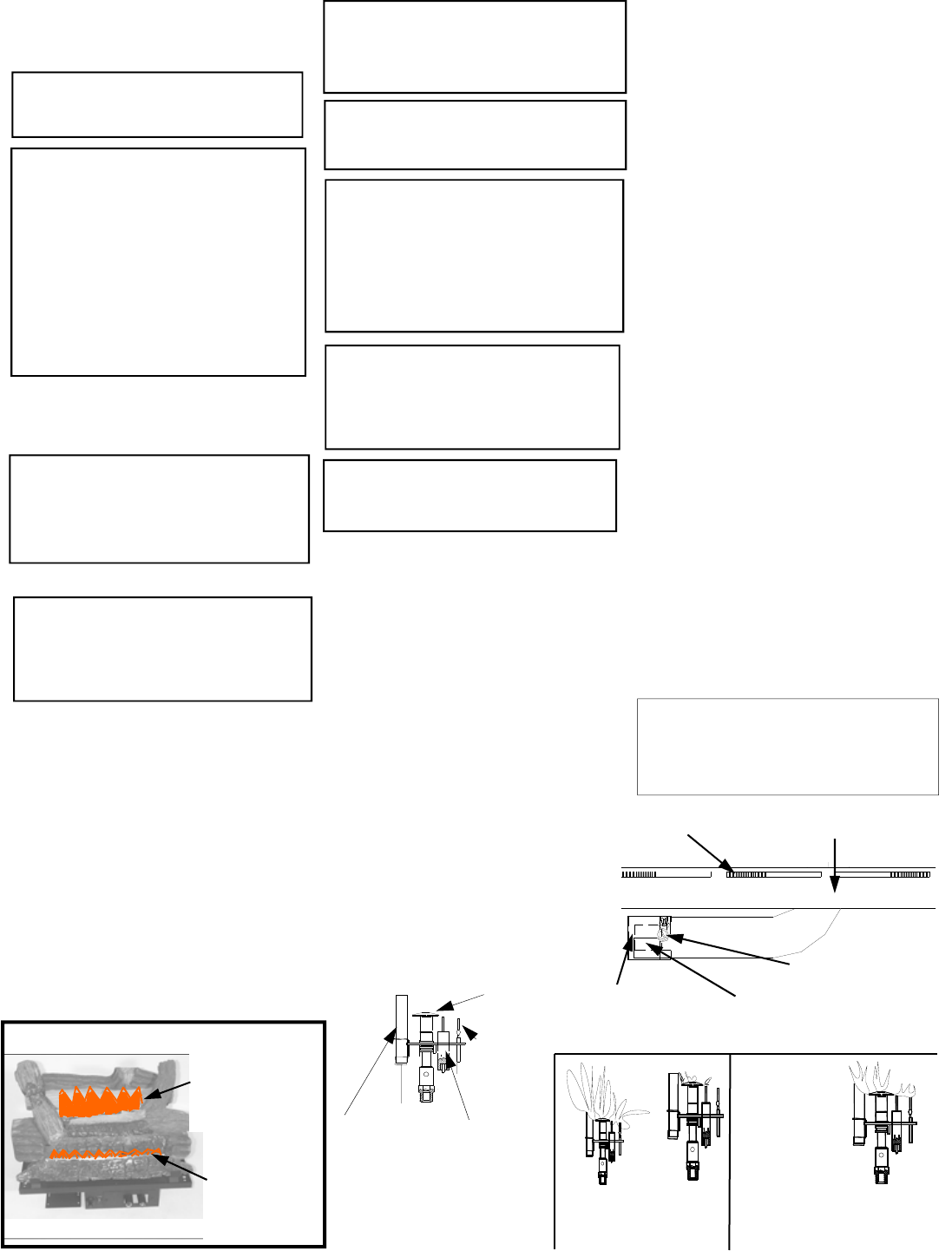

CORRECT FLAME PATTERN

PHILLIPS SCREW

AIR SHUT-

TER

AIR SHUTTER SLOTS

BURNER SLOTS

BURNER TUBE

BURNER/ AIR SHUTTER

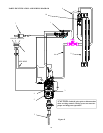

NOTE: For direct vent design,

proper reassembly and resealing of

the vent-air intake system. (see Page

9, also Figure 20, on page 11)

Incorrect flame patterns

Correct flame pattern

PILOT

Pilot Burner

Ignitor Electrode

Thermocouple

Thermopile

CAUTION: The appliance area must

be kept clear and free from combusti-

ble materials, gasoline and other flam-

mable vapors and liquids.

NOTE: The flow of combustion and

ventilation air must not be obstructed.

Rear Flame Should

Be Approximately 2”

to 3” Above the Rear

Log, With Yellow

Tips.

The Front Flame

Should Be Ap-

proximately 1” to 1

1/2” Up From The

Front Burner Tube,

And Be Blue In

Color.

Flame should

engulf the tip end

of the Thermo-

pile and the Ther-

mocouple, and

should be con-

stant. The flame

should be

Blue in color.

And 3/4” to 1” in height.

25