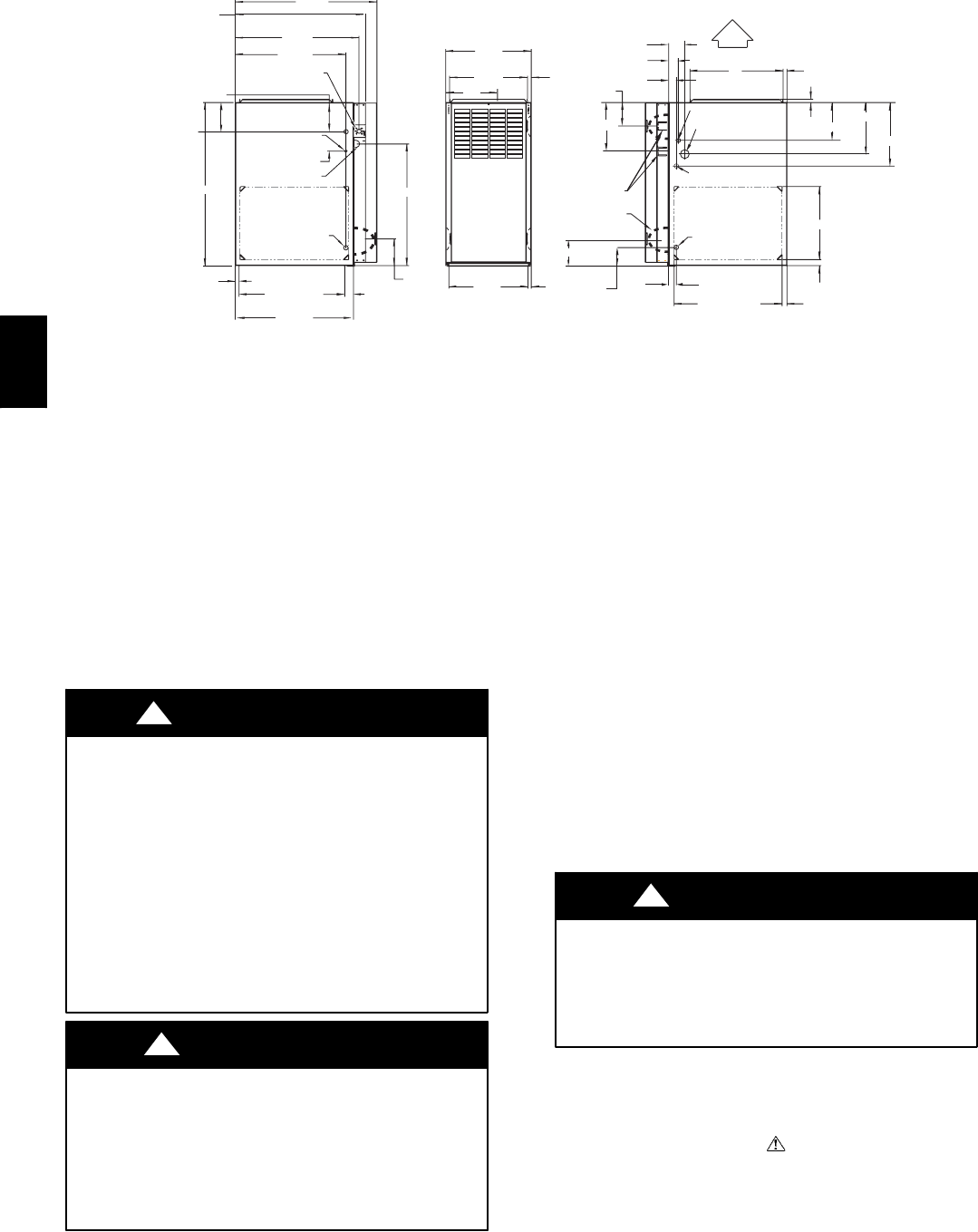

2

2-7/16"

1-1/8"

28-7/8"

25-1/4"

22-9/16"

JUNCTION BOX

LOCATION

7/8" DIA

ACCESSORY

1/2" DIA THERMOSTAT

WIRE ENTRY

3-15/16"

LEFT HAND GAS

ENTRY

33-5/16"

24-7/8"

5-1/2"

7/8" DIA. ACCESSORY

11/16"

21-5/8"

BOTTOM INLET

1-11/16"

13/16"

11/16"

4-13/16"

AIRFLOW

19"

OUTLET

13/16"

11/16"

8-9/16"

VENT OUTLET

5 PLACES (TYP)

3-3/4"

1-3/4" DIA.RIGHT HAND

GAS ENTRY

7/8" DIA. K.O. WIRE ENTRY

SIDE INLET

14-7/8"

7/8" DIA. ACCESSORY

1-1/4"

1"

22-1/16"

A

D

F

E

(FLUE COLLAR)

5-15/16"

24"

CASING

1-5/16"

1/2" DIA. K.O.THERMOSTAT

WIRE ENTRY

ALTERNATE

JUNCTION BOX

LOCATIONS (TYP)

26-1/8"

1-1/2"

7-3/4"

9-5/8"

11-1/2"

5-1/2"

NOTES:

1. Two additional 7/8-in. diameter holes are located in the top plate.

2. Minimum return-air openings at furnace, based on metal duct. If flex duct is used, see flex duct manufacturer’s recommendations for equivalent diameters.

a. For 800 CFM-16-in. round or 14 1/2 x 12-in. rectangle.

b. For 1200 CFM-20-in. round or 14 1/2 x 19 1/2-in. rectangle.

c. For 1600 CFM-22-in. round or 14 1/2 x 22-in. rectangle.

d. For airflow requirements above 1800 CFM, see Air Delivery table in Product Data literature for specific use of single side inlets. The use of both side inlets

a combination of 1 side and the bottom, or the bottom only will ensure adequate return air openings for airflow requirements above 1800 CFM.

A04037

NOTES:

1. Two additional 7/8---in. diameter holes are located in the top plate.

2. Minimum return--- air openings at furnace, based on metal duct. If flex duct is used, see flex duct manufacturer’s recommendations for equivalent

diameters.

a. For 800 CFM---16---in. round or 14 1/2 x 12---in. rectangle.

b. For 1200 CFM---20---in. round or 14 1/2 x 19 1/2---in. rectangle.

c. For 1600 CFM---22---in. round or 14 1/2 x 22---in. rectangle.

d. For airflow requirements above 1800 CFM, see Air Delivery table in Product Data literature f or specific use of single side inlets. The use of both sidein-

lets, a combination of 1 side and the bottom, or the bottom only will en sure adequate return air openings for airflow requirements above 1800 CFM.

Fig. 1 -- Dimensional Drawing

SAFETY CONSIDERATIONS

FIRE, EXPLOSION, ELECTRICAL SHOCK, AND

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in dangerous

operation, serious injury, death, or property damage.

Improper installation, adjustment, alteration, service,

maintenance, or use could cause carbon monoxide

poisoning, explosion, fire, electrical shock, or other

conditions which may cause personal injury or property

damage. Consult a qualified service agency, local gas

supplier, or your distributor or branch for information or

assistance. The qualified service agency must use only

factory--authorized and listed kits or accessories when

modifying this product.

!

WARNING

FURNACE RELIABILITY HAZARD

Improper installation or misapplication of furnace may

require excessive servicing or cause premature component

failure.

Application of this furnace should be indoors with special

attention given to vent sizing and material, gas input rate,

air temperature rise, unit leveling, and unit sizing.

CAUTION

!

Installing and servicing heating equipment can be hazardous due

to gas and electrical components. Only trained and qualified

personnel should install, repair, or service heating equipment.

Untrained personnel can perform basic maintenance functions

such as cleaning and replacing air filters. All other operations

must be performed by trained service personnel. When working

on heating equipment, observe precautions in literature, on tags,

and on labels attached to or shipped with furnace and other safety

precautions that may apply. These instructions cover minimum

requirements and conform to existing national standards and

safety codes. In some instances, these instructions exceed certain

local codes and ordinances, especially those that may not have

kept up with changing residential construction practices. We

require these instructions as a minimum for a safe installation.

CUT HAZARD

Failure to follow this caution may result in personal injury.

Sheet metal parts may have sharp edges or burrs. Use care

and wear appropriate protective clothing, safety glasses and

gloves when handling parts and servicing furnaces.

CAUTION

!

Wear safety glasses and work gloves. Have fire extinguisher

available during start--up and adjustment procedures and service

calls.

This is the safety--alert symbol

. When you see this symbol

on the furnace and in instructions or manuals, be alert to the

potential for personal injury.

Understand the signal words DANGER, WARNING, and

CAUTION. These words are used with the safety--alert symbol.

DANGER identifies the most serious hazards which will result in

severe personal injury or death. WARNING signifies a hazard

which could result in personal injury or death. CAUTION is used

to identify hazards which may result in minor personal injury or

312A