12

underneath furnace must be level and the furnace set on blocks or

bricks.

Roll--Out Pr

otection

Provide a minimum 17--3/4 in. X 22 in. piece of sheet metal for

flame roll--out protection in front of burner area for furnaces

closer than 12 inches above the combustible deck or suspended

furnaces closer than 12 inches to joists. The sheet metal MUST

extend underneath the furnace casing by 1 in. with the door

removed.

The bottom closure panel on furnaces of widths 17--1/2 in. and

larger may be used for flame roll--out protection when bottom of

furnace is used for return air connection. See Fig. 17 for proper

orientation of roll--out shield.

Bottom Return Air

Inlet

These furnaces are shipped with bottom closure panel installed in

bottom return--air opening. Remove and discard this panel when

bottom return air is used. To remove bottom closure panel,

perform the following:

1. Tilt or raise furnace and remove 2 screws holding bottom

filler panel. (See Fig. 9.)

2. Rotate bottom filler panel downward to release holding

tabs.

3. Remove bottom closure panel.

4. Reinstall bottom filler panel and screws.

Side Return Air

Inlet

These furnaces are shipped with bottom closure panel installed in

bottom return--air opening. This panel MUST be in place when

side return air inlet(s) are used without a bottom return air inlet.

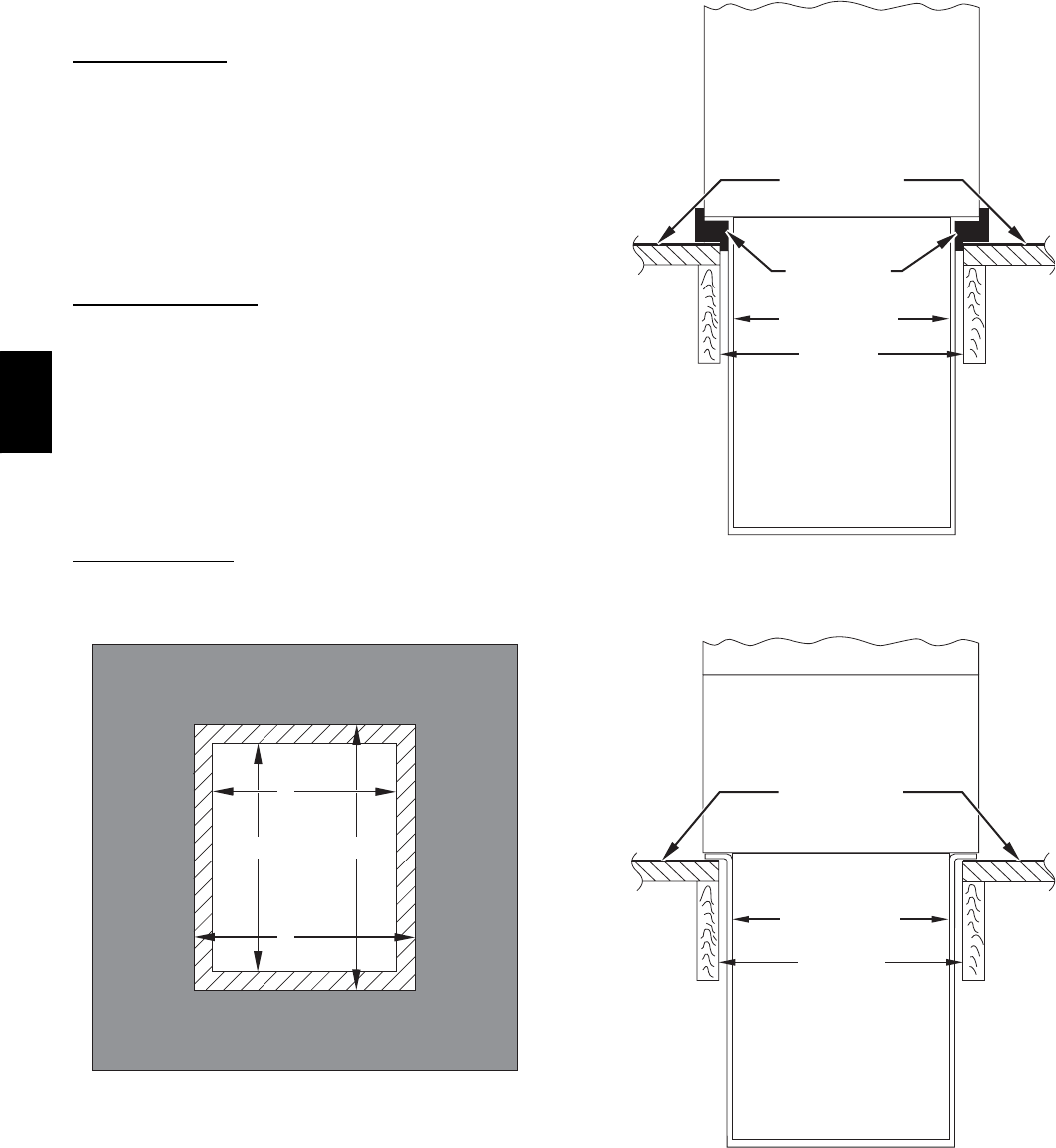

PLENUM

OPENING

C

A

B

D

FLOOR

OPENING

A096283

Fig. 11 -- Floor and Plenum Opening Dimensions

DOWNFLOW

SUBBASE

SHEET METAL

PLENUM

FLOOR

OPENING

FURNACE

(OR COIL CASING

WHEN USED)

COMBUSTIBLE

FLOORING

A096285

Fig. 12 -- Furnace, Plenum, and Subbase installed on a

Combustible Floor

A04140

CD5 OR CK5

COIL ASSEMBLY

OR KCAKC

COIL BOX

FURNACE

SHEET METAL

PLENUM

FLOOR

OPENING

COMBUSTIBLE

FLOORING

A04140

Fig. 13 -- Furnace, Plenum, and Coil Assembly or Coil Box

Installed on a Combustible Floor

312A