23

12.4 Fitting the twin pipe (Ø80/80)

NOTE:

S

EE PAGE 2

4

FOR MAXIMUM AND MINIMUM FLUE RUNS (

T

ABLE C

)

Where it is not possible to terminate the flue within the distance permitted for coaxial flues, the twin flue pipe can be used by

fitting a special adaptor to the flue connector and using the aperture for the air intake located on top of the combustion

c

hamber.

A

lways ensure that the flue is adequately supported, avoiding low points. (MTS supply suitable clamps as Part No. 705778).

To utilise the air intake it is necessary to:

1) Take the air intake cover off

2) Assemble the flange on the header supplied with the boiler

3) Insert the restrictor if necessary, on the tube or the elbow

4) Insert the header on the tube or the elbow up until the lower stop

(you do not have to use the washer).

5) Insert the elbow/header in the boiler air intake hole and fasten it with screws

The twin flue pipes can be fitted with or without additional elbows and need no clamps, simply ensure that the red o-ring is

inserted in the female end of the flue pipe and push the extension piece fully into the previous section of flue pipe or elbow,

check that the o-ring is not dislodged when assembling the flue.

Twin pipe can also be converted back to Coaxial flue to enable vertical termination with a coaxial kit by using the pipe bridge

(Twin - Coaxial Adaptor - Part No. 705767). When running the twin flue pipe vertically.

It is not recommended that the pipe bridge for horizontal termination, however in the unlikely event that this proves to be a

necessity it is extremely important that the entire flue has a fall of 5mm in every metre back to the boiler, and where the 60mm

inner flue of the concentric terminal connects to the pipe bridge, this point must be adequately sealed with silicone sealant to

avoid condense leakage at this point.

When siting the twin flue pipe, the air intake and exhaust terminals must terminate on the same wall, the centres of the

terminals

must be a minimum of 280 mm apart and the air intake must not be sited above the exhaust terminal. The air intake

pipe can be run horizontally, however, the terminal and the final 1 metre of flue must be installed with a fall away from the

boiler to avoid rain ingress.

It is also strongly recommended that the air intake pipe run be constructed of insulated pipe to prevent condense forming on

the outside of the tube.

The maximum permissible flue length for twin flue is dependent on the type of run used.

For flue runs with the intake and exhaust pipes under the same atmospheric conditions (T

YPE 4) the maximum length is 60

metres (24kW and 30kW), for runs with the terminals under different atmospheric conditions (T

YPE 5) the exhaust terminal

must extend 0.5 metres above the ridge of the roof (this is not obligatory if the exhaust and air intake pipes are located on the

same side of the building). For T

YPE 5 also, the maximum permissible combined length is 60 metres (24kW and 30kW).

The maximum length is reached by combining the total lengths of both the air intake and exhaust pipes.

Therefore a maximum

length of 60 metres for example, will allow a flue run of 30 metres for the air intake and 30 metres for the exhaust pipes, also

for each 90

o

elbow 2.2 metres must be subtracted from the total length and for each 45

o

elbow 1.4 metres must be subtracted

from the total flue length.

Some of the acceptable flue configurations are detailed page 24.

For further information relating to flue runs not illustrated, please contact the Technical Department on 0870 241 8180.

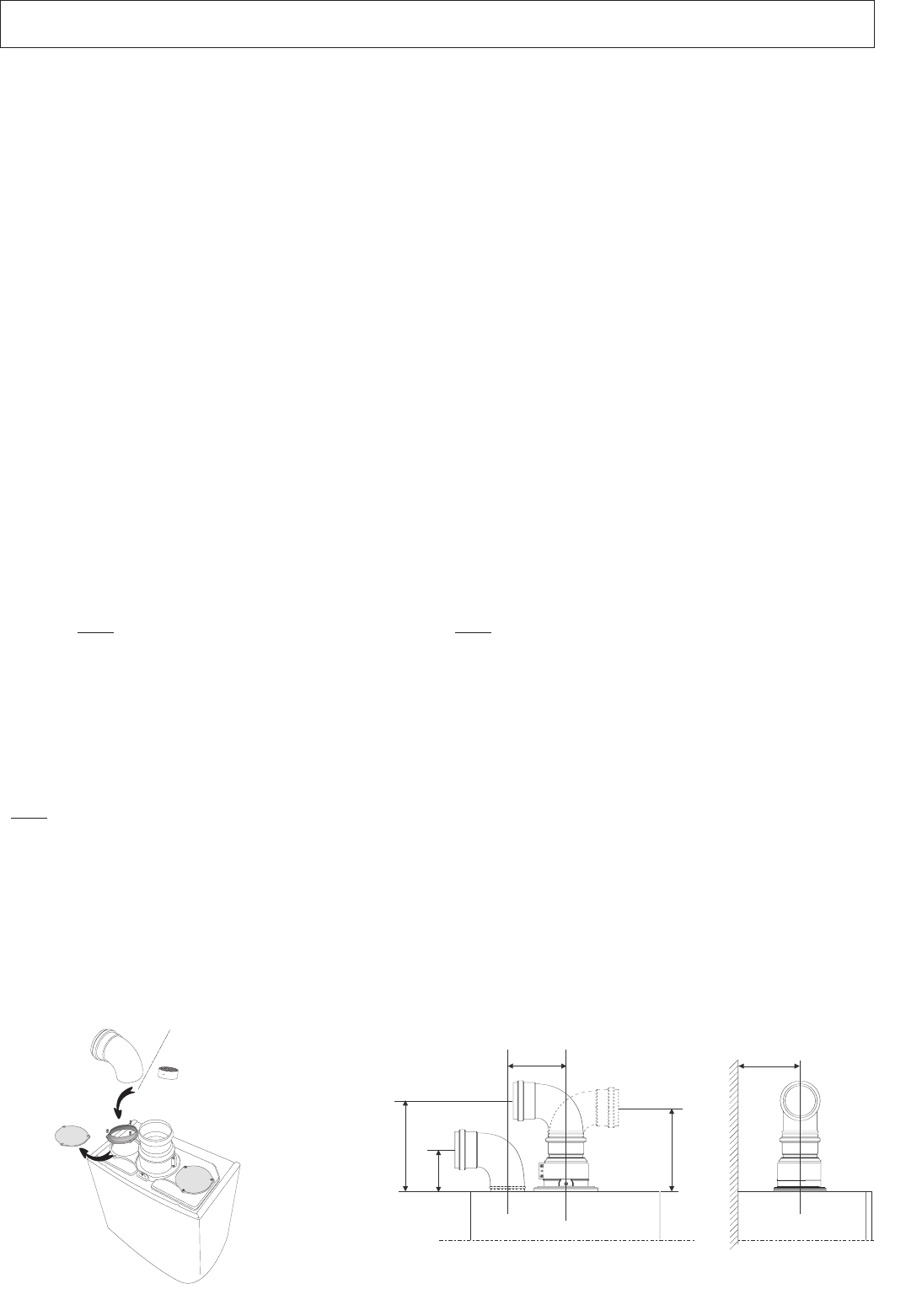

12. Connecting the flue (continued)

B23

C53

123,5 162

230 MIN *

200

132

Fig. 25

Fig. 26

162