IDRIVE

®

FOR TORQUEMASTER

®

INSTALLATION

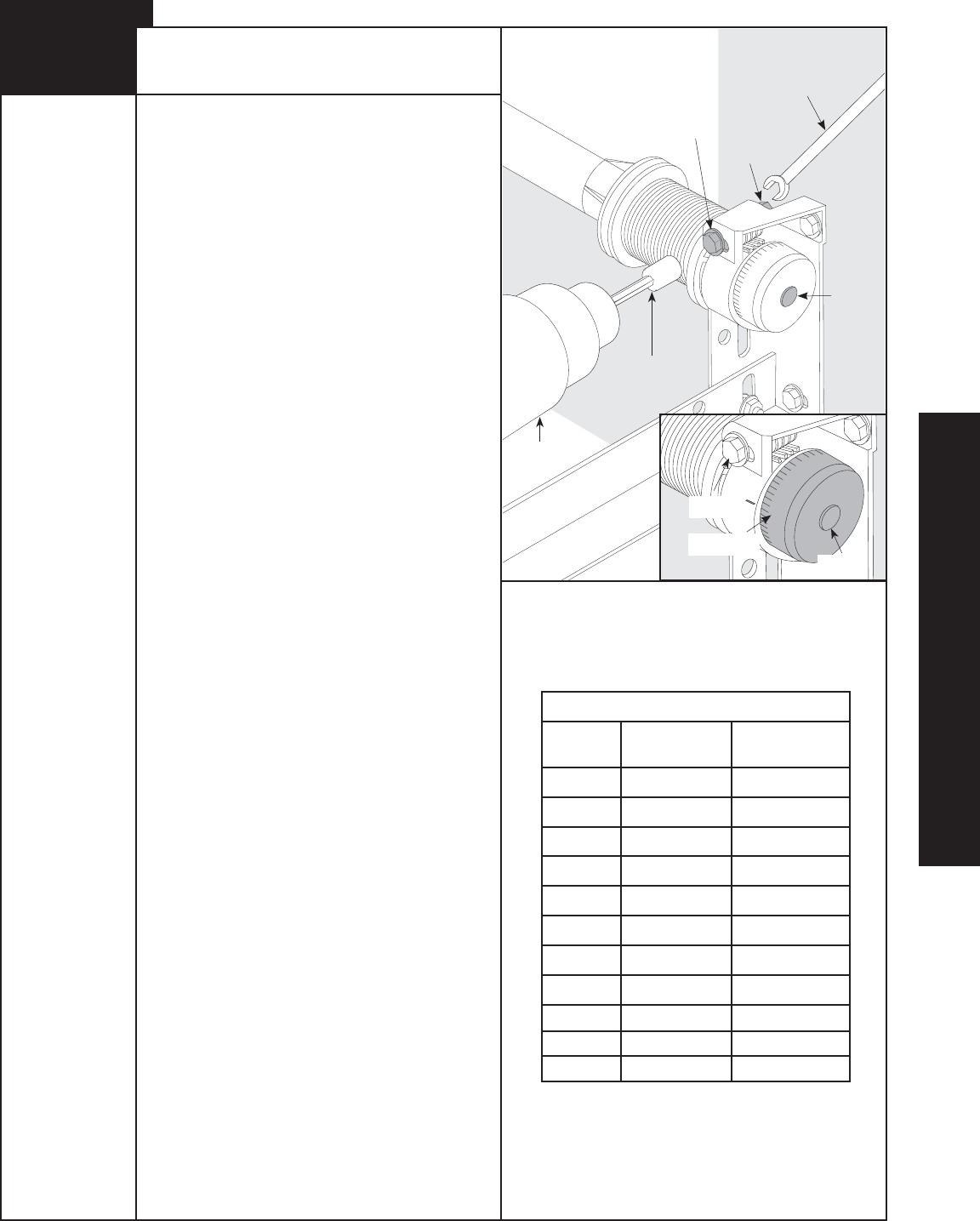

Setting Spring Tension

See chart below for proper spring tension setting.

Beginning with the right hand side, ensure the

counterbalance cable is in the first groove of the cable drum.

NOTE: Apply light pressure to the canoe clip on counter

while winding springs.

Using a power drill (high torque/gear reduced to 1300 RPM

preferred) with a 7/16" socket driver, carefully rotate right

hand winding bolt clockwise, until counter shows 2-3 turns.

This will keep the counterbalance cable taut while adjusting

the left hand side counterbalance cable.

Adjust left hand counterbalance cable tension (Refer to step

10).

NOTE: Single spring applications require no spring winding

on left hand side, but need cable tension adjusted.

IMPORTANT! Ensure counterbalance cable tension is

equal for both sides prior to fully winding spring(s) to

appropriate number of turns. If cable tension is unequal,

refer to Step 10.

See the Spring Turn chart.

For SINGLE SPRING applications, return to the right hand

side and carefully rotate the winding bolt head clockwise

until the counter shows the correct number of turns for your

door or the number record during the Pre-Installation

Inspection on page II.

For DOUBLE SPRING applications, remain on the left

hand side and carefully rotate the winding bolt head

clockwise until the counter shows the correct number of

turns for your door or the number record during the Pre-

Installation Inspection on page II. Then return to the right

hand side and wind the right hand spring to the required

number of turns for your door or the number recorded

during the Pre-Installation inspection on page II.

IMPORTANT! DO NOT OVERWIND.

After spring is wound, hold the lock nut (in back of end

bracket) stationary with a 7/16" wrench while rotating the

winding bolt clockwise until snug. Tightening of the lock nut

prevents spring from unwinding. Repeat for opposite side on

double spring Torquemaster

®

systems.

IMPORTANT! CAUTIOUSLY REMOVE VICE CLAMPS FROM

VERTICAL TRACKS. ADJUSTMENTS TO THE RECOMMENDED

NUMBER OF TURNS MAY BE REQUIRED. IF DOOR RAISES OFF

FLOOR UNDER SPRING TENSION ALONE, THEN REDUCE UNTIL

RESTS ON FLOOR. IF IS HARD RAISE OR DRIFTS DOWN ITS

OWN, ADD TENSION. AN UNBALANCED CAN CAUSE IDRIVE

®

OPERATION PROBLEMS.

IMPORTANT! IF YOU ARE INSTALLING THE IDRIVE

®

OPENER ON A NEW GARAGE DOOR, REAR SUPPORTS WILL

NEED TO BE FABRICATED/ INSTALLED TO SUPPORT THE

HORIZONTAL TRACKS. REAR SUPPORTS ARE CONSTRUCTED

USING PERFORATED ANGLES, HEX HEAD BOLTS/NUTS AND

THEN THE MUST BE SECURELY ATTACHED TO SOUND

FRAMING MEMBERS WITH LAG SCREWS. FOR DETAILED

INFORMATION ON CONSTRUCTING/ SUPPORTING THE REAR

SUPPORTS, REFER TO YOUR DOORS INSTALLATION

INSTRUCTIONS AND OWNER’S MANUAL.

RECOMMENDED SPRING TURNS

Door Height Doors 11’-11”

Wide or Less

Doors 12’ Wide or

Greater

6’-0” 13-1/2 14

6’-3” 14 14-1/2

6’-5” 14-1/2 15

6’-6” 14-1/2 15

6’-8” 15 15-1/2

6’-9” 15 15-1/2

7’-0” 15-1/2 16

7’-3” 16 16-1/2

7’-6” 16-1/2 17

7’-9” 17 17-1/2

8’-0” 17-1/2 18

NOTE: For 7’ high doors, 8’, 9’, 10’, 16’ or 18’

wide with windows, the recommended number of

spring turns is 15.

Tools Needed:

Power Drill

7/16" Socket

Driver

7/16" Wrench

Step Ladder

Canoe Clip

Winding

Bolt

Power

Drill

7/16”

Socket

Driver

15.5

Counter

(Sample Setting)

Winding

Bolt

Canoe Clip

12

TorqueMaster

®

7/16”

Wrench

Lock Nut

20

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need.

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com