4

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need.

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

R3

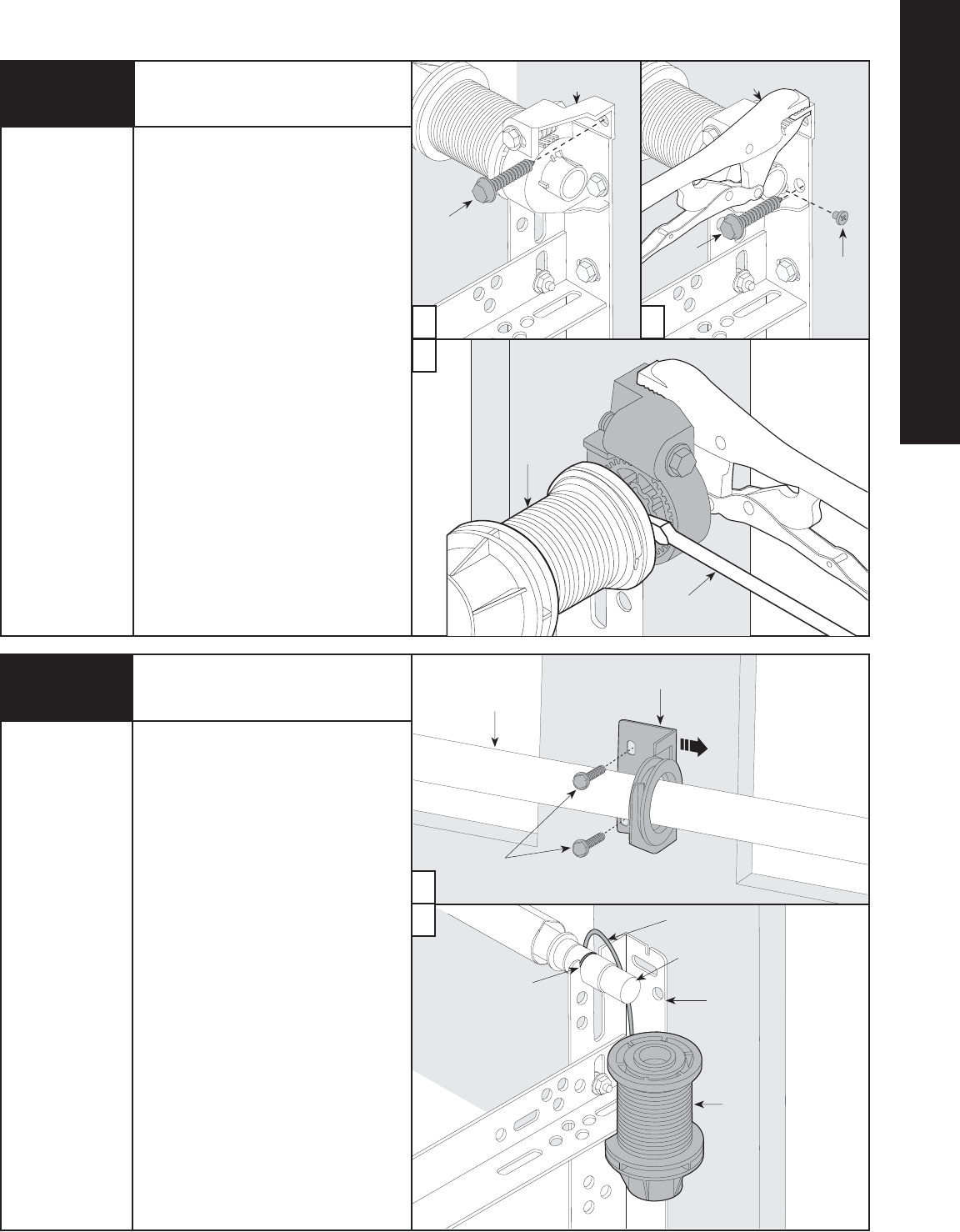

End Bracket Removal

To remove the end brackets, follow the

steps below starting with the right hand

end bracket first:

a. Remove the upper lag screw from the

end bracket.

b. Attach a pair of locking pliers to the

upper portion of the end bracket and

hold the end bracket steady while

removing the lower lag screw.

If present, remove and save the #10

phillips head screw.

c. Holding the end bracket with the locking

pliers, carefully pry the end bracket from

the cable drum with a flat tip

screwdriver.

Repeat for left hand end bracket.

CAUTION: THE WINDING SHAFT MAY

ROTATE WHEN REMOVING THE END

BRACKET AND GEAR.

Center Bracket & Cable Drum

Removal

To remove the cable drum/center bracket,

follow the steps below:

a. Remove the two 1/4" lag screws from

the center bracket. Slide center bracket

to the right side of the torque tube.

Lift the right side of the torque tube up

and slide the cable drum and center

bracket off the end of the torque tube.

Discard the center bracket.

b. Drape the cable drum over the flagangle

by the counterbalance cable and re-align

the groove in the winding shaft with the

round notch in the flagangle.

Once aligned, lower the winding shaft

and torque tube onto the flagangle.

Repeat cable drum removal for left side.

After completing this step, continue with

Step R5 on page 5.

R4

Upper

Lag Screw

Lower

Lag Screw

#10 Phillips

Head

Screw

Flat Tip

Screwdriver

a b

c

a

b

1/4”

Lag Screws

Center

Bracket

Torque

Tube

Winding

Shaft

Round Notch

in Flagangle

Cable

Drum

Cable

Drum

RETRO-FIT TORQUEMASTER

®

Tools Needed:

Locking Pliers

Phillips Head

Screwdriver

Flat Tip

Screwdriver

Power Drill

7/16” Socket

Driver

Step Ladder

Tools Needed:

Power Drill

7/16" Socket

Driver

Step Ladder

End

Bracket

Locking

Pliers

Flagangle

Counterbalance

Cable