– 14 –

Table 3-2-5 Flare and flare nut dimensions for R410A

Table 3-2-3 Dimensions related to flare processing for R410A

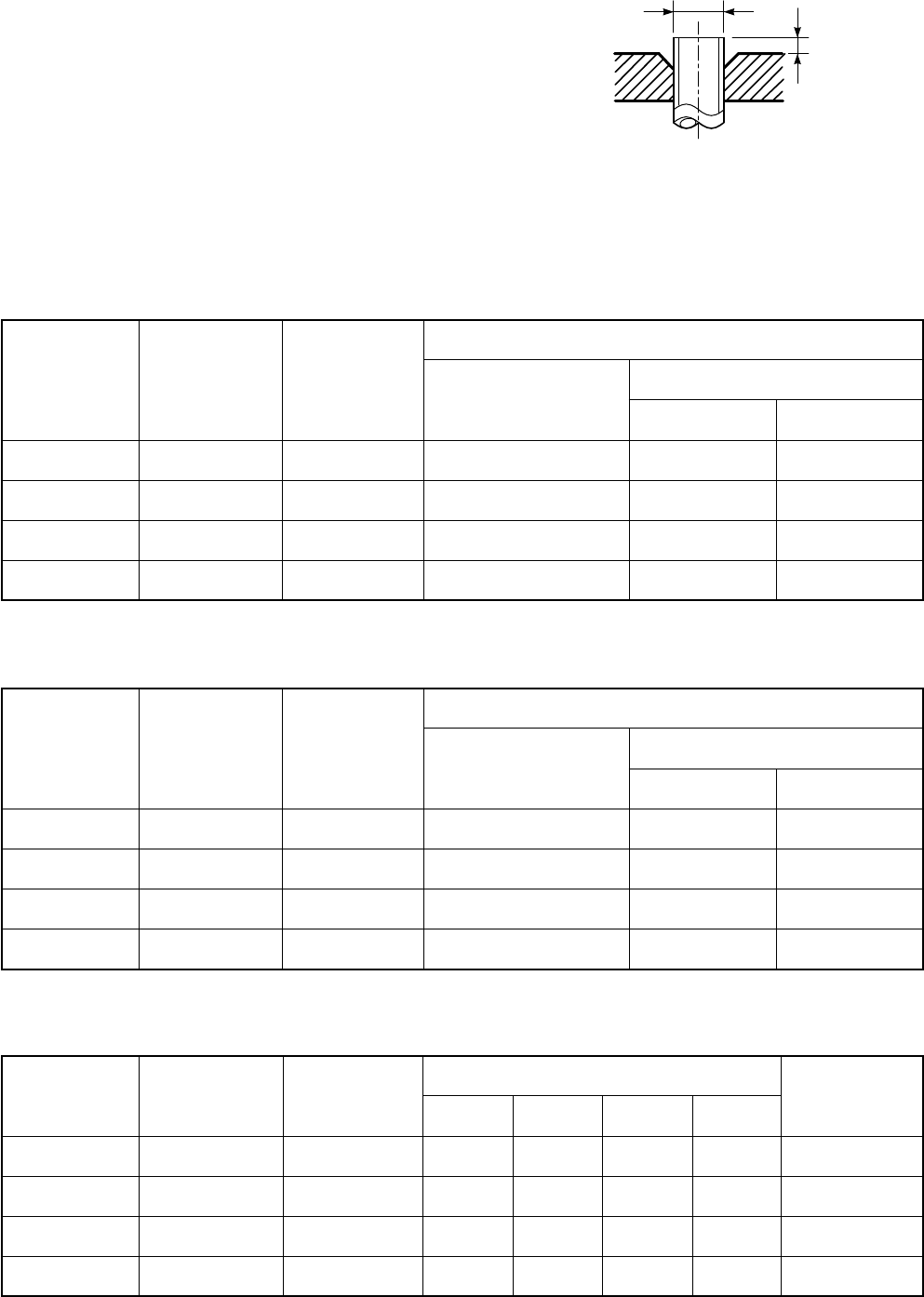

d) Flare Processing

Make certain that a clamp bar and copper

pipe have been cleaned.

By means of the clamp bar, perform the flare

processing correctly.

Use either a flare tool for R410A or conven-

tional flare tool.

Flare processing dimensions differ according

to the type of flare tool. When using a

conventional flare tool, be sure to secure

“dimension A” by using a gauge for size

adjustment.

Fig. 3-2-1 Flare processing dimensions

A

ØD

Nominal

diameter

1/4

3/8

1/2

5/8

Outer

diameter

(mm)

6.35

9.52

12.70

15.88

Thickness

(mm)

0.8

0.8

0.8

1.0

A (mm)

Flare tool for R410A

Conventional flare tool

clutch type

Clutch type Wing nut type

0 to 0.5 1.0 to 1.5 1.5 to 2.0

0 to 0.5 1.0 to 1.5 1.5 to 2.0

0 to 0.5 1.0 to 1.5 2.0 to 2.5

0 to 0.5 1.0 to 1.5 2.0 to 2.5

Table 3-2-4 Dimensions related to flare processing for R22

Nominal

diameter

1/4

3/8

1/2

5/8

Outer

diameter

(mm)

6.35

9.52

12.70

15.88

Thickness

(mm)

0.8

0.8

0.8

1.0

A (mm)

Flare tool for R410A

Conventional flare tool

clutch type

Clutch type Wing nut type

0 to 0.5 0.5 to 1.0 1.0 to 1.5

0 to 0.5 0.5 to 1.0 1.0 to 1.5

0 to 0.5 0.5 to 1.0 1.5 to 2.0

0 to 0.5 0.5 to 1.0 1.5 to 2.0

Nominal

diameter

1/4

3/8

1/2

5/8

Outer

diameter

(mm)

6.35

9.52

12.70

15.88

Thickness

(mm)

0.8

0.8

0.8

1.0

Dimension (mm)

ABCD

9.1 9.2 6.5 13

13.2 13.5 9.7 20

16.6 16.0 12.9 23

19.7 19.0 16.0 25

Flare nut

width

(mm)

17

22

26

29