Form 421, Page 4

4. Uncrating and Preparation

This furnace was test operated and inspected at the factory prior to

crating and was in operating condition. If the furnace has incurred any

damage in shipment, file a claim with the transporting agency.

Check the rating plate for the gas specifications and electrical charac-

teristics of the furnace to be sure that they are compatible with the gas

and electric supplies at the installation site. Read this booklet and be-

come familiar with the installation requirements of your particular fur-

nace. If you do not have knowledge of local requirements, check with

the local gas company or any other local agencies who might have

requirements concerning this installation. Before beginning, make

preparations for necessary supplies, tools, and manpower.

Check to see if there are any field-installed options that need to be

assembled to the furnace prior to installation.

Option Parts -- Some gas control options will have parts either shipped

loose with the heater or shipped separately. If your unit is equipped

with any of the following gas control options, be sure these parts are

available at the job site.

Other shipped-separate options could include a gas shutoff valve, a

condensate drain fitting, a thermostat, a hanger kit, a coupling kit, a fan

control, or high temperature sealing tape.

5. Location, Clearances, and

Combustion Air

Unit must be installed so that the following clearances are provided for

combustion air space, service and inspection, and for proper spacing

from combustible construction.

NOTE: See Figure 5 for service clearance illustration.

CAUTION: Do not locate heater where it may

be exposed to liquid spray, rain or dripping

water.

These duct furnaces are designed to take combustion air from the space

in which the furnace is installed. The air that enters into the combus-

tion process is vented to the outdoors. Sufficient air must enter the

equipment location to replace the air exhausted through the vent sys-

tem. Modern construction methods involve the greater use of insula-

tion, improved vapor barriers and weather-stripping, with the result

that buildings generally are much tighter structurally than they have

been in the past. The combustion air supply for gas-fired equipment

can be affected by these construction conditions because infiltration

that would have existed in the past may not be adequate. Extensive use

of exhaust fans aggravates the situation. In the past the filtration of

outside air assumed in heat loss calculations (one air change per hour)

was assumed to be sufficient. However, current construction methods

may now require the introduction of outside air through wall openings

or ducts.

WARNING: These furnaces are designed to take

combustion air from the space in which the unit

is installed and are not designed for connection

to outside combustion air intake ducts. Use of

outside air ducts voids the warranty and could

cause hazardous operation. (See Hazard Levels,

page 2.)

Requirements for combustion air and ventilation air depend upon

whether the unit is located in a confined or unconfined space. An "un-

confined space" is defined as a space whose volume is not less than 50

cubic feet per 1000 BTUH of the installed appliance. Under all condi-

tions, enough air must be provided to ensure there will not be a nega-

tive pressure condition within the equipment room or space. A posi-

tive seal must be made in all return-air connections and ducts. Even a

slight leak can create a negative pressure condition in a confined space

and affect combustion.

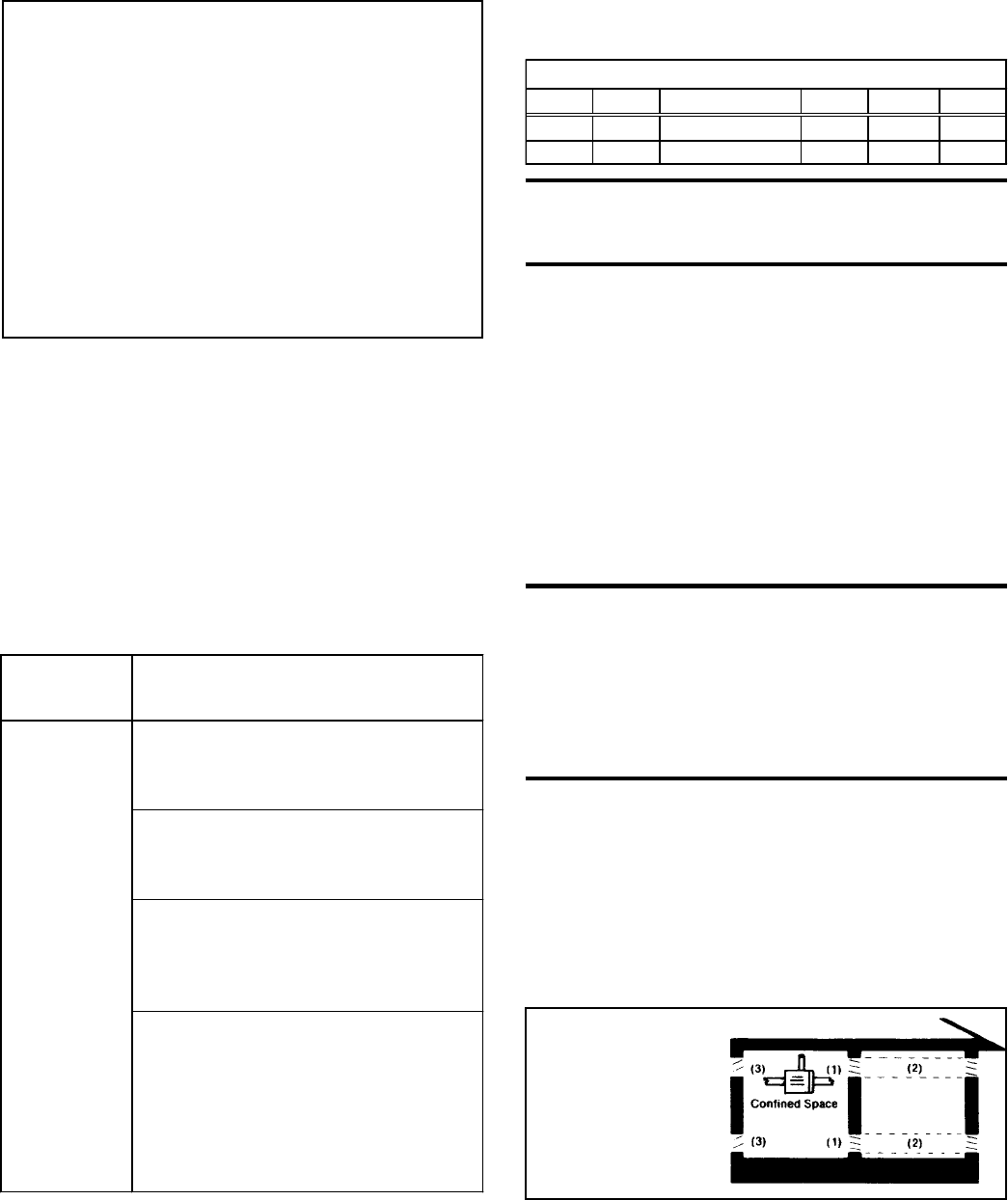

Installation in a Confined Space

Do not install a unit in a confined space without providing wall open-

ings leading to and from the space. Provide openings near the floor

and ceiling for ventilation and air for combustion as shown in Figure

CAUTION: Remove the panel from the bottom rear of the

furnace (See Paragraph 28) and check the burner rack as-

sembly. The burner rack "drawer" should be setting level with

each side on a support rail. Check to assure that EXCES-

SIVE shipping vibration has not caused the burner rack as-

sembly to "drop off" the support rails into the bottom pan. If

the burner rack assembly is positioned properly, close the

back panel. If the burner rack has fallen, remove the screws

holding the burner rack assembly and pull out the burner rack

"drawer". Re-assemble by sliding the burner rack "drawer"

into the heater, being sure that both sides are resting on the

support rails. Re-attach to the support brackets underneath

the burners. Re-insert the burner rack screws and close the

back panel.

Figure 2 -

Confined Space: A

space whose volume

is less than 50 cubic

feet per 1000 BTUH

of the installed

appliance input

rating

Heating -- Gas Option AG7

Control Option

Amplifier, P/N 48035

Thermostat, P/N 48033

Makeup Air -- Option AG3

Gas Control

Control Switch, P/N 29054

Options

Gasket, P/N 7726

Gasket Retainer Plate, P/N 7727

(All of these Option AG8

options also

Temperature Sensor, P/N 48041

require a

Amplifier, P/N 48037

shipped-

Control Switch, P/N 29054

separate fan Option AG9

control, Opt

Remote Temperature Selector, P/N 48042

CQ1 (P/N

Temperature Sensor, P/N 48041

57960), which

Amplifier, P/N 48035

should be

Control Switch, P/N 29054

at the job Option AG15 or AG16

site.

Remote Temperature Selector, P/N 115848

Stage Adder Module, P/N 115849

Control Switch, P/N 29054

Transformer 115 to 24V, P/N 103055 or

208/230 to 24V, P/N 103497; and 1/2" locknut,

P/N 16222 (for transformer)

Display Module, P/N 115852

(AG16 only)

REQUIRED CLEARANCES

Front Top Flue Connector Sides Bottom Rear

6" 6" 6" 6" 12" 29"

152mm 152mm 152mm 152mm 305mm 737mm