RGM Form 421, Mfg No. 150492, Page 11

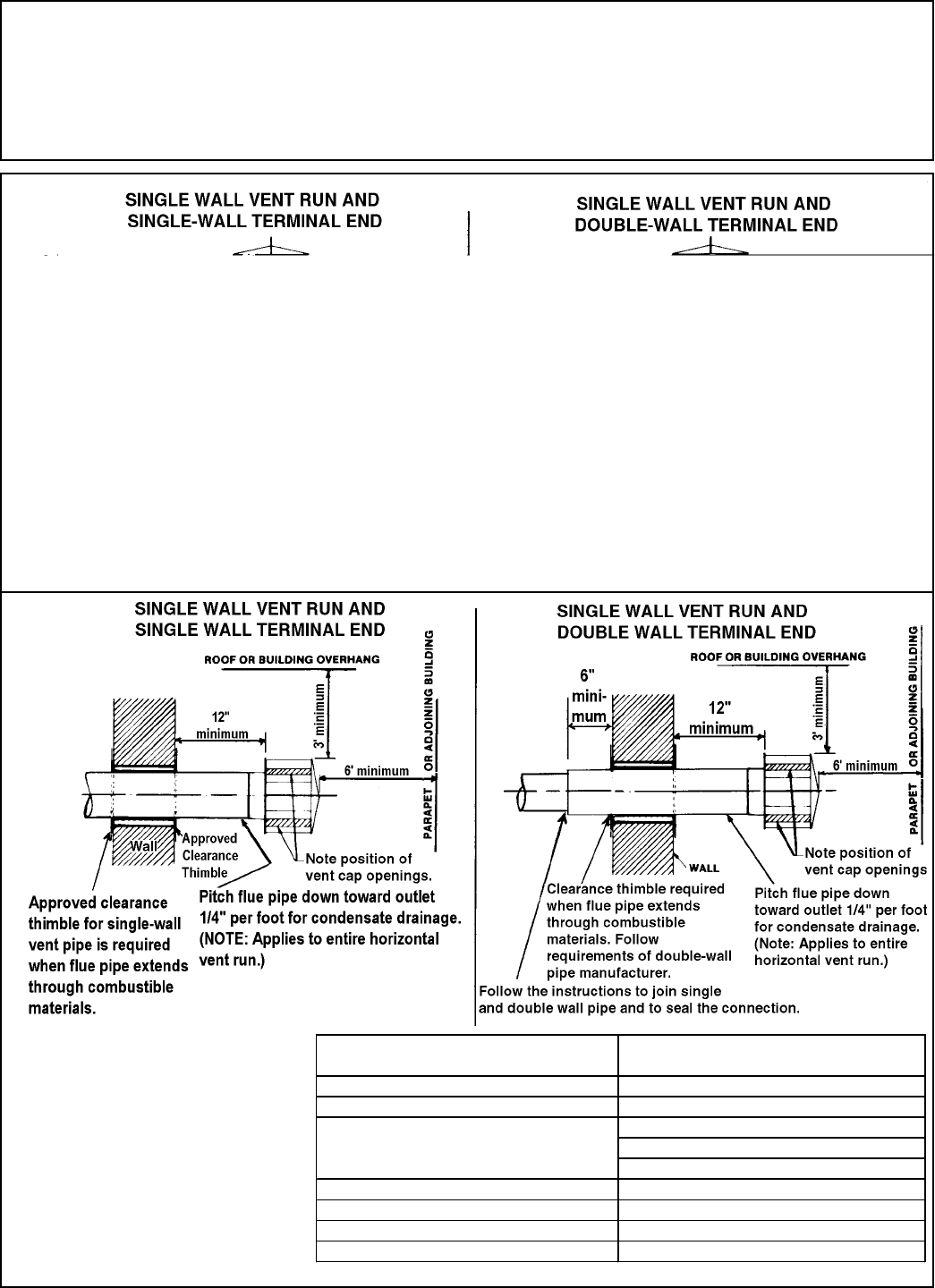

Figure 9 -

Vertical

Vent

Terminal

Horizontal Vent Terminal Clearances

The location of the termination of the hori-

zontal vent system must be in accordance with

National Fuel Gas Code Z223.1. See table for

required minimum clearances.

If the vent terminal is to be installed near

ground level, position it at least six inches

above maximum anticipated snow depth.

NOTE: Maintain the required clearance

from the wall to the vent terminal cap for

stability under wind conditions and to pro-

tect the building.

Figure 10 -

Horizontal

Vent

Terminal

Instructions to connect the SINGLE WALL VENT system to a

DOUBLE WALL (Type B) VENT TERMINAL:

1) Slide the single wall pipe inside the inner wall of the double-wall

terminal pipe.

2) Drill a hole through both walls of the double wall pipe and the

single wall pipe. (Hole should be slightly smaller than the sheet

metal screws being used .) Using a 3/4" long sheet metal screw,

attach the two pieces of pipe. Do not overtighten.

3) Repeat Step 2) drilling and inserting two additional screws evenly

spaced (120

°

apart).

4) To seal the annular opening (the gap between the single and double

wall pipe), run a large bead of silicone sealant in the opening. The

bead of sealant must be large enough to seal the opening, but it is

not necessary to fill the full volume of the annular area.

Structure

Minimum Clearances for Vent Termination

Location (all directions unless specified)

Forced air inlet within 10 ft (3.1m) 3 ft (0.9m) above

Combustion air inlet of another appliance 6 ft (1.8m)

4 ft (1.2m) horizontally

4 ft (1.2m) below

3 ft (0.9m) above

Electric meter, gas meter * and relief equipment 4 ft (1.2m) horizontally

Gas regulator * 3 ft (0.9m)

Adjoining building or parapet 6 ft (1.8m)

Grade (ground level) 7 ft (2.1m) above

*Do not terminate the vent directly above a gas meter or service regulator.

Door, window or gravity air inlet (any building

opening)