9.8.(d): If additional fluid is necessary for any reason, use only the fluid identified on the

nameplate to ensure compatibility with the installed seals and the specified operating temperature

range. DO NOT OVER-FILL.

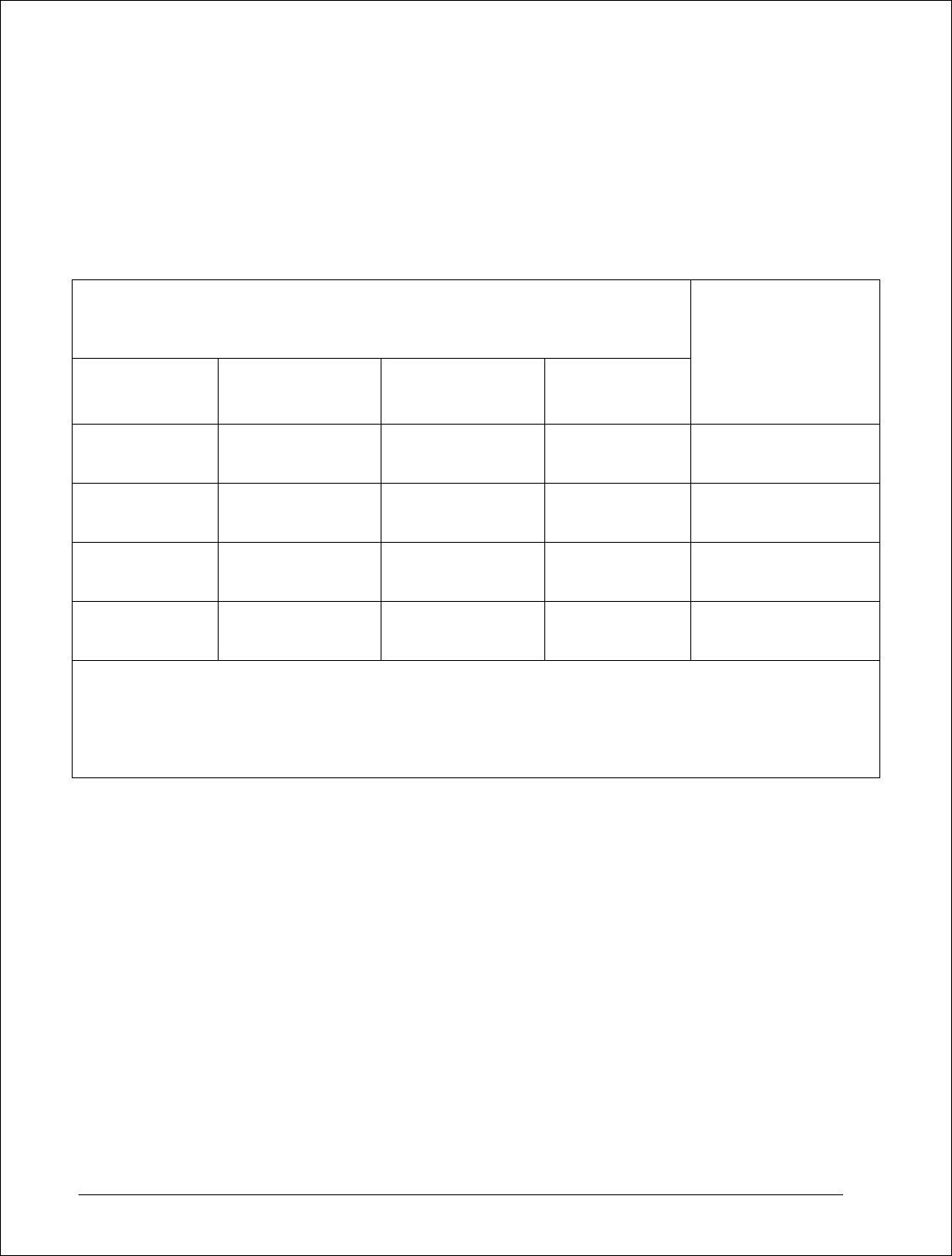

9.8.(e): Table 3 specifies Recommended Hydraulic Fluid types for a range of ambient

temperatures.

Table 3: Recommended Hydraulic Fluids

Ambient Temperature

Hydraulic

Fluid

Lower Limit

0

F

Upper Limit

0

F

Lower Limit

0

C

Upper Limit

0

C

-13

+122

-25

+50

C-10 (1)

+32

+176

0

+80

C-46 (1)

-31

+104

-35

+40

Aero 41 (2)

-76

+140

-60

+60

M-20 (3)

(1) C-10 and C-46 are Shell Tellus® products.

(2) Aero 41 is a Shell® product.

(3) M-20 is a Bayer® Baysilone product.

All hydraulic fluids are obtainable from Magnetek.

9.9: Brake Adjustments

9.9.(a): Wear will be more rapid when the linings are new, while the high spots are wearing down

as the bedding process takes place. Adjustment will be required soon after the brake has been

put into service.

9.9.(b): Brake release lever travel increases with lining wear. This decreases the reserve stroke.

Carry out periodic maintenance to reset the reserve stroke as described in Chapter 6 “Actuator

Stroke Adjustment”.

9.9.(c): Brake torque decreases as the brake lever drops. On critical applications, such as

hoists, brake adjustment should be performed frequently enough so that the torque loss does not

result in loss of load control. In no event should the lever be allowed to “bottom out”. This results

in total loss of braking torque and could result in death or injury to personnel.

8/17/2006 Page 31 of 33 MST/E Electric Shoe Brakes Manual

560022-R6

Following any adjustment, maintenance or repair on the brake, fully test its operation as

described under topic “Operational Test”.