Installation and

Service Manual

39

9. Inspect the liquid level in the expansion tank. The system

must be full and under normal operating pressure to ensure

proper water level in the expansion tank. Ensure that

diaphragm type expansion tanks are properly charged and

not water logged.

10. Start the boiler according to the operating instructions in this

manual. Operate the system, including the pump, boiler and

radiation units, for one hour.

11. Recheck the water level in the expansion tank. If it exceeds

half the tank volume, open the tank to reduce the water level.

Recheck pressure charge on diaphragm type tanks.

12. Shut down the entire system and vent all radiation units and

high points in the system.

13. Close the water makeup valve and check the strainer and

pressure reducing valve for sediment or debris. Reopen the

water makeup valve.

14. Verify system pressure with the boiler pressure gauge before

beginning regular operation.

15. Within three days of startup, recheck and bleed all air vents

and the expansion tank using these instructions.

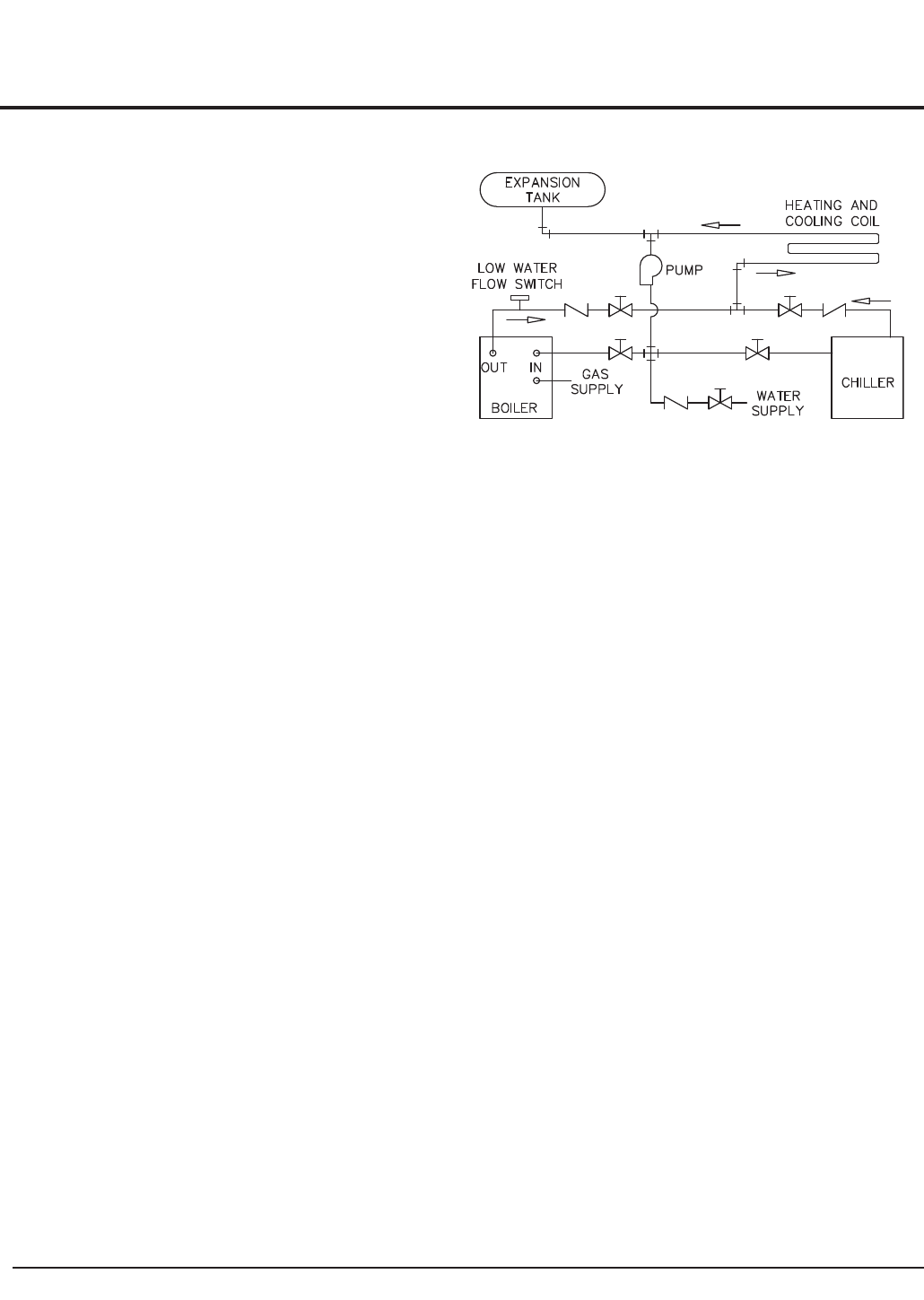

Installation with a Chilled Water

System

Pipe refrigeration systems in parallel. Install duct coil

downstream at cooling coil. Where the hot water heating boiler

is connected to a heating coil located in the air handling units

which may be exposed to refrigeration air circulation, the

boiler piping system must be equipped with flow control

valves or other automatic means to prevent gravity circulation

of the boiler water during the cooling cycle. The coil must be

vented at the high point and hot water from the boiler must

enter the coil at this point. Due to the fast heating capacity of

the boiler, it is not necessary to provide a ductstat to delay

circulator operation. Also, omit thermostat flow checks as the

boiler is cold when heating thermostat is satisfied. This

provides greater economy over maintaining standby heat (see

FIG. 41).

FIG. 41 Installation with a Chilled Water System

Boiler Operating Temperature Control

This unit can have up to four sensors. The four sensors are for

inlet temperature, outlet temperature, system/tank temperature,

or outdoor air temperature.

If the unit is ordered as a boiler without any options and you

need remote sensing, you can relocate either the inlet or outlet

sensors. For best performance, do not relocate the inlet or

outlet sensors. Install an optional system sensor.

If the unit is ordered as a water heater, the tank sensor is

included with the unit. Do not relocate the inlet or outlet

sensors from their bulbwells.

The digital electronic operating temperature control for these

units is located on the front control panel. The sensing

elements for the temperature control are placed in the inlet and

outlet bulbwells. See Remote Mounting of Sensors (Outdoor

Air Sensor), on page 48 of this manual. Carefully observe the

discharge water temperature on the initial boiler “ON” cycles.

The location of the temperature sensor will generally require a

lower temperature set point on the operating control to achieve

the desired discharge water temperature from the boiler. These

sensing element locations allow a boiler operating with a low

to moderate flow rate to sustain longer burner on cycles,

preventing short boiler “ON” cycles based on high discharge

water temperatures. For example, a boiler operating with a

180°F (82°C) discharge and a 20°F (11°C) temperature rise

would require approximately a 160°F (71°C) to 165°F (74°C)

set point with the temperature sensor installed on the inlet side

of the heat exchanger. The exact temperature set point is based

on your system’s requirements.