12

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

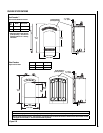

Figure 13

Step 3. INSTALL THE VENT SYSTEM

General Information

These instructions should be used as a guide-

line and do not supersede local codes in any

way. Install vent according to local codes,

these instructions, the current National Fuel

Gas Code (ANSI-Z223.1) in the USA or the cur

-

rent standards of CAN/CSA-B149 in Canada.

These fireplaces are designed, tested and

listed for operation and installation with,

and only with, Secure Vent™ Direct Vent

System Components, Secure Flex™ Flexible

Vent Components manufactured by Security

Chimneys International and Z-FLEX™

Model

GA Venting Systems listed to UL1777 and

ULCS635 manufactured by Flexmaster Canada

Limited. These approved vent system compo-

nents are labeled for identification. DO NOT

use any other manufacturer's vent components

with these appliances.

Vertical (Straight) Installation

Determine the number of straight vent sections

required. 4-1/2" (114 mm), 10-1/2" (267 mm),

22-1/2" (572 mm), 34-1/2" (876 mm) and 46-

1/2" (1181 mm) net section lengths are available.

Plan the vent lengths so that a joint does not

occur at the intersection of ceiling or roof joists.

Refer to the Vent Section Length Chart.

These fireplaces must be vented directly

to the outside.

The vent system may not service multiple

appliances, and must never be connected to a

flue serving a solid fuel burning appliance. The

vent pipe is tested to be run inside an enclosing

wall (such as a chase). There is no requirement

for inspection openings in the enclosing wall at

any of the joints in the vent pipe.

Select Venting System - Horizontal or Verti-

cal

With the appliance secured in framing, de-

termine vent routing and identify the exterior

termination location. The following sections

describe vertical (roof) and horizontal (exterior

wall) vent applications. Refer to the section

relating to your installation. A list of approved

venting components are shown in the tables

on Page 30.

VERTICAL TERMINATION SYSTEMS (ROOF)

Figures 17, and 23 through 25 on Pages

14 and 16 and their associated Vertical

Vent Tables illustrate the various vertical venting

configurations that are possible for use with

these appliances. Secure Vent pipe applications

are shown in these figures; Secure Flex pipe

may also be used.

A Vertical Vent Table summarizes each system’s

minimum and maximum vertical and horizontal

length values that can be used to design and

install the vent components in a variety of

applications.

Both these vertical vent systems terminate

through the roof. The minimum vent height

above the roof and/or adjacent walls is speci-

fied in ANSI Z223.1-(latest edition) (In Canada,

the current CAN/CSA-B149 installation code)

by major building codes. Always consult your

local codes for specific requirements. A general

guide to follow is the Gas Vent Rule (refer to

Figure 6 on Page 8).

SV4.5H

T -2

T ermination

SV4.5F A OR

SV4.5FB Flashing

AND SV4.5SC

STORM COLLAR

SV4.5VF

Firestop/Spacer

SV4.5L6/12/24/36/48

V ent Sections

40' Max.

(12.2 M)

6' Min.

(1.8 M)

1" (25.4 mm)

Minimum

Clearance to

Combustibles

When using Secure

Flex,

use Firestop/Spacer

SF4.5VF

Figure 12

Step 2. ROUTING GAS LINE

Route a 1/2" (13 mm) gas line along the inside

of the left side framing as shown in

Figure 12.

Gas lines must be routed, constructed and made

of materials that are in strict accordance with

local codes and regulations.

All appliances are factory-equipped with a

flexible gas line connector and 1/2 inch shutoff

valve.

(See Step 7 on Page 24).

6-1/8"

(156 mm)

*1-7/8"

(65 mm)

Right Side Front

Corner of Fire-

place Framing

* Measured from the top of

platform that unit is installed on

to pipe center (see Figure 9)

FPO