30

IO-247A 12/04

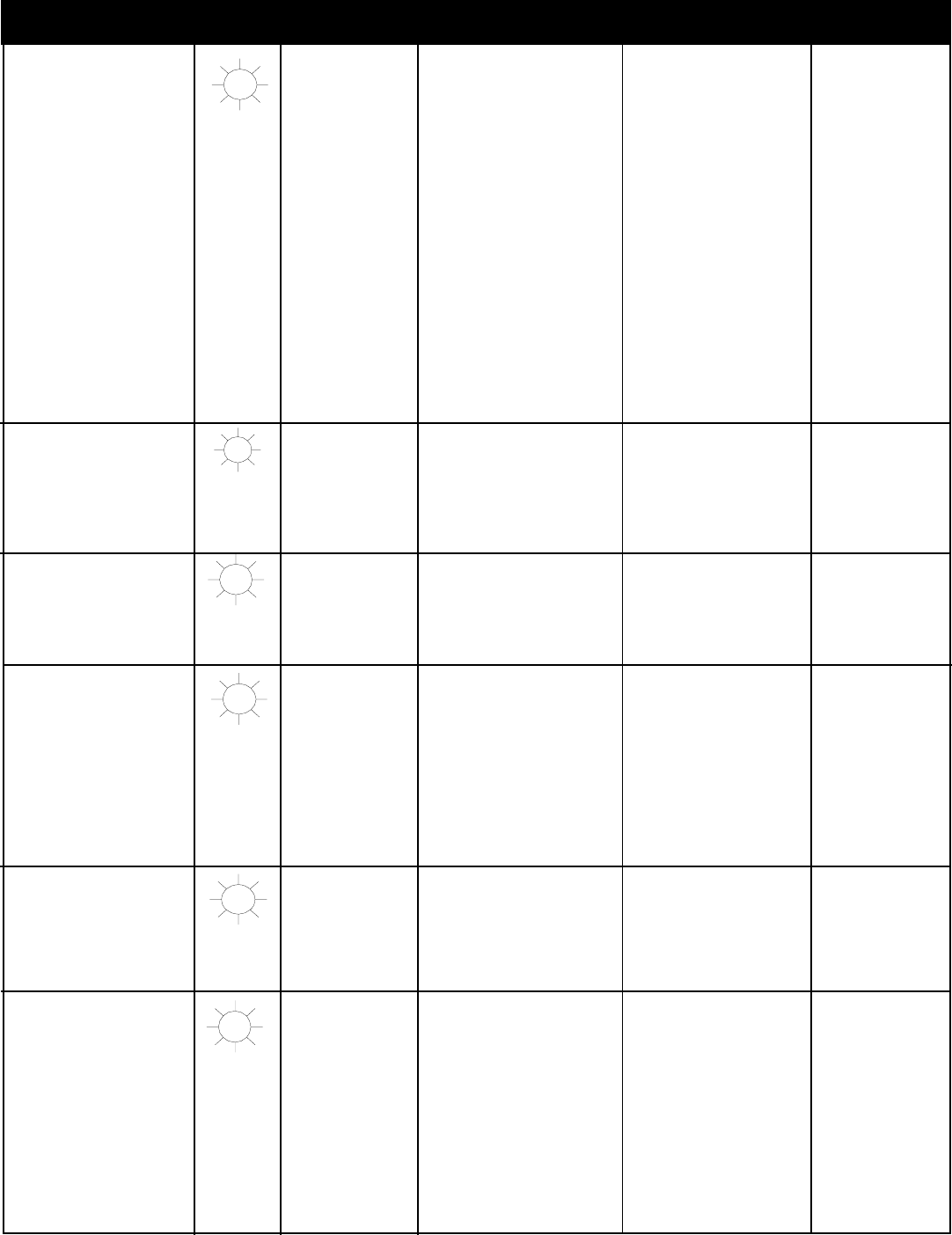

Troubleshooting Chart

Fault Description(s)

Symptoms of Abnormal

Operation

4

4 FLASHES

Associated

LED Code

2

•Circulator blower runs

continuously. No furnace

operation.

•Integrated control module

diagnostic LED is flashing

FOUR (4) flashes.

7

7 FLASHES

•Normal furnace

operation.

•Integrated control

module diagnostic LED

is flashing SEVEN (7)

flashes.

• Furnace fails to operate.

• Integrated control module

diagnostic LED is flashing

continuously.

C

CONTINUOUS

FLASHING

•Primary limit

circuit is open.

•Polarity of 115

volt power is

reversed.

•Flame sense

microamp signal is

low.

•Insufficient conditioned air

over the heat exchanger.

Blocked filters, restrictive

ductwork, improper

circulator blower speed,

or failed circulator blower.

•Flame rollout.

•Misaligned burners,

blocked flue and/or air

inlet pipe, or failed

induced draft blower.

•Loose or improperly

connected wiring.

Possible Causes Corrective Action Cautions and Notes

•Check filters and

ductwork for blockage.

Clean filters or remove

obstruction.

•Check circulator blower

speed and performance.

Correct speed or replace

blower if necessary.

•Check burners for proper

alignment.

•Check flue and air inlet

piping for blockage,

proper length, elbows,

and termination. Correct

as necessary.

•Check induced draft

blower for proper

performance. Replace, if

necessary.

•Tighten or correct wiring

connection.

•Turn power OFF

prior to repair.

•See Product Data

Bulletin for

allowable rise

range and proper

circulator speed.

See “Vent/Flue

Pipe” section for

piping details.

•Replace pressure

switch with proper

replacement part.

•Polarity of 115 volt AC

power to furnace or

integrated control module

is reversed.

•Poor unit ground.

•Flame sensor is coated/

oxidized.

•Flame sensor incorrectly

positioned in burner

flame.

•Lazy burner flame due to

improper gas pressure or

combustion air.

•Review wiring diagram to

correct polarity.

•Verify proper ground.

Correct if necessary.

•Check and correct wiring.

•Sand flame sensor is

coated/oxidized.

•Inspect for proper sensor

alignment.

•Check inlet air piping for

blockage, proper length,

elbows, and termination.

•Compare current gas

pressure to rating plate

info. Adjust as needed.

•Turn power OFF

prior to repair.

•Turn power OFF

prior to repair.

•Sand flame

sensor with

emery clot.

•See “Vent/Flue

Pipe” section for

piping details.

•See rating plate

for proper gas

pressure.

• Inspect

pressure

switch

hose.

Repair, if necessary.

• Inspect flue and/or inlet

air piping for blockage,

proper length, elbows,

and termination.

Check

drain

system.

Correct

as

necessary.

• Correct pressure switch

setpoint or

contact

motion.

• Tighten

or

correct

wiring

connection.

9

9 FLASHES

•Furnace not operating.

•Integrated control module

diagnostic LED is flashing

EIGHT (8) flashes.

• Furnace operating on

low stage gas with high

stage induced draft blower

• High stage circulator

blower (temperature, of

conditioned air, lower than

typical).

•Integrated control module

diagnostic LED is flashing

NINE (9) flashes.

8

8 FLASHES

• High stage

pressure switch

circuit does not

close in response

to high stage

induced draft

blower operation.

•Problem with

igniter circuit.

•Improperly

connected igniter

•Bad igniter

•Poor unit ground

• Pressure switch hose

blocked, pinched or

connected improperly.

• Blocked flue and/or inlet air

pipe, blocked drain system,

or weak induced draft

blower.

• Incorrect pressure switch

setpoint or malfunctioning

switch contacts.

• Loose or improperly

connected wiring.

•Check and correct wiring

from integrated control

module to igniter

•Replace bad igniter

•Check and correct unit

ground

wiring

•Turn power OFF

prior to repair.

•Replace igniter

with proper

silicon nitride

replacement part.

•Turn power OFF

prior to repair.

•Replace pressure

switch with

proper

replacement part.

• Integrated control module

diagnostic LED is flashing

FIVE (5) times.

•Induced draft blower and

circulator blower run

continuously. No furnace

operation.

• Flame sensed with

no call for heat.

•Correct short at flame

sensor or in flame

sensor wiring.

•Check for lingering

flame

•Verify proper operation

of gas valve

•Short to ground in flame

sense circuit.

•Lingering burner flame.

•Slow closing gas valve

•Turn power OFF

prior to repair.

5

5 FLASHES