24

IO-247A 12/04

5. Turn ON gas and relight appliances turned off in step 1.

Ensure all the appliances are functioning properly and that

all pilot burners are operating.

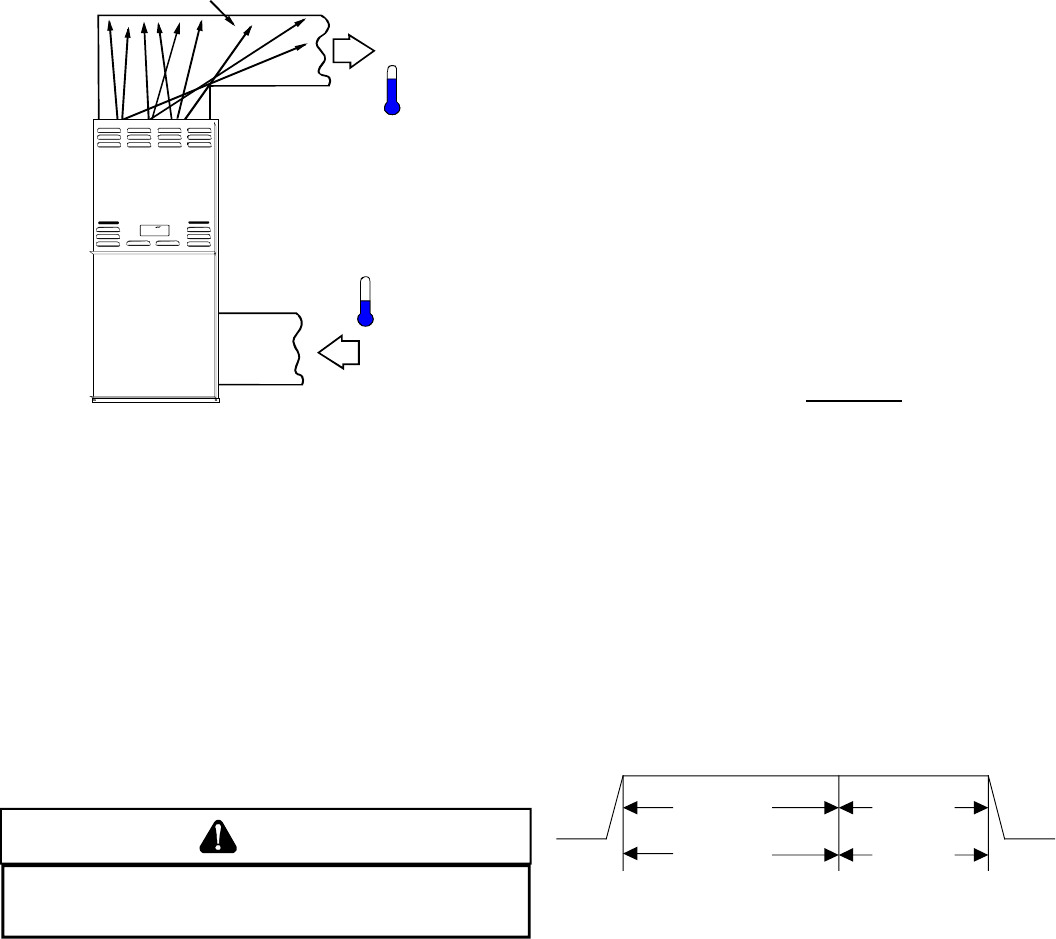

TEMPERATURE RISE

Air temperature rise is the temperature difference between supply

and return air. The proper amount of temperature rise is usually

obtained when the unit is operated at the rated input with the “as

shipped” blower speed. If the correct amount of temperature rise

is not obtained, it may be necessary to change the blower speed.

An incorrect temperature rise can cause condensing in or

overheating of the heat exchanger. Determine and adjust the

temperature rise as follows. The temperature rise must be within

the range specified on the rating plate or Product Data Book

applicable to your model*.

RISE =

SUPPLY

AIR

RETURN

AIR

HEAT EXCHANGER

RADIATION "LINE OF SIGHT"

T

RETURN

T

SUPPLY

T

SUPPLY

-

T

RETURN

Temperature Rise Measurement

1. Operate furnace with burners firing approximately 15

minutes. Ensure all registers are open and all duct dampers

are in their final (fully or partially open) position.

2. Place thermometers in the return and supply ducts as close

to the furnace as possible. Thermometers must not be

influenced by radiant heat by being able to “see” the heat

exchanger.

3. Subtract the return air temperature from the supply air

temperature to determine the air temperature rise. Allow

adequate time for thermometer readings to stabilize.

4. Adjust temperature rise by adjusting the circulator blower

speed. Increase blower speed to reduce temperature rise.

Decrease blower speed to increase temperature rise. Refer

to the following section for speed changing details.

CIRCULATOR BLOWER SPEED ADJUSTMENT

WARNING

T

O AVOID PERSONAL INJURY OR DEATH DUE TO ELECTRICAL SHOCK, TURN

OFF

POWER TO THE FURNACE BEFORE CHANGING SPEED TAPS.

All furnaces are shipped with heating speed set at “B” and cooling

speed set at “D”. Use the following procedure to select the heating

and cooling speed needed for your unit.

Use the CFM LED (green), adjacent to the integrated control

module fuse to verify airflow quantity. The green CFM LED

blinks once for each 100 CFM of airflow.

1. Determine the tonnage of the cooling system installed with

the furnace. If the cooling capacity is in BTU/hr divide it by

12,000 to convert capacity to TONs.

Example: Cooling Capacity of 30,000 BTU/hr.

30,000/12,000 = 2.5 Tons

2. Determine the proper air flow for the cooling system. Most

cooling systems are designed to work with air flows between

350 and 450 CFM per ton. Most manufacturers recommend

an air flow of about 400 CFM per ton.

Example: 2.5 tons X 400 CFM per ton = 1000 CFM

The cooling system manufacturer’s instructions must be checked

for required air flow. Any electronic air cleaners or other devices

may require specific air flows, consult installation instructions of

those devices for requirements.

3. Knowing the furnace model, locate the high stage cooling

air flow charts in the Product Data Book applicable to your

model* . Look up the cooling air flow determined in step 2

and find the required cooling speed and adjustment setting.

Example: A 70 kBtu furnace is to be installed with a 2.5

ton air conditioning system. The air flow

needed is 1000 CFM. Using the cooling speed

chart for the 70 kBtu furnace, find the airflow

closest to 1000 CFM. A cooling airflow of 990

CFM can be attained by setting the cooling

speed to “C” and the adjustment to “-” (minus).

NOTE: Continuous Fan Speed will be 56% of

high stage cooling.

4. Locate the blower speed selection DIP switches on the

integrated control module. Select the desired “cooling”

speed tap by positioning switches 1 and 2 appropriately.

Select the desired “adjust” tap by positioning switches 3

and 4 appropriately. Refer to the following figure for switch

positions and their corresponding taps. Turn off power to

furnace for a minimum of

10 seconds, allowing motor to

reset and recognize new speed selection. Turn on power

to furnace. Verify CFM by counting the number of times the

green CFM LED blinks.

5. The multi-speed circulator blower also offers several custom

ON/OFF ramping profiles. These ramping profiles may be

used to enhance cooling performance and increase comfort

level. The ramping profiles are selected using DIP switches

5 and 6. Refer to the following figure for switch positions

and their corresponding taps. Refer to the bullet points below

for a description of each ramping profile. Turn off power to

furnace for a minimum of 10 seconds, allowing motor to

reset and recognize the new profile selection. Turn on power

to the furnace. Verify profile selection by counting the green

CFM LED blinks and timing each step of the ramping profile

• Profile A provides only an OFF delay of 1 minute at 100% of

the cooling demand airflow.

100% CFM

1 min

100% CFM

Cooling

Demand

OFF OFF

• Profile B ramps up to full cooling demand airflow by first

stepping up to 50% of the full demand for 30 seconds. The

motor then ramps to 100% of the required airflow. A 1 minute

OFF delay at 100% of the cooling airflow.