11

IO-247A 12/04

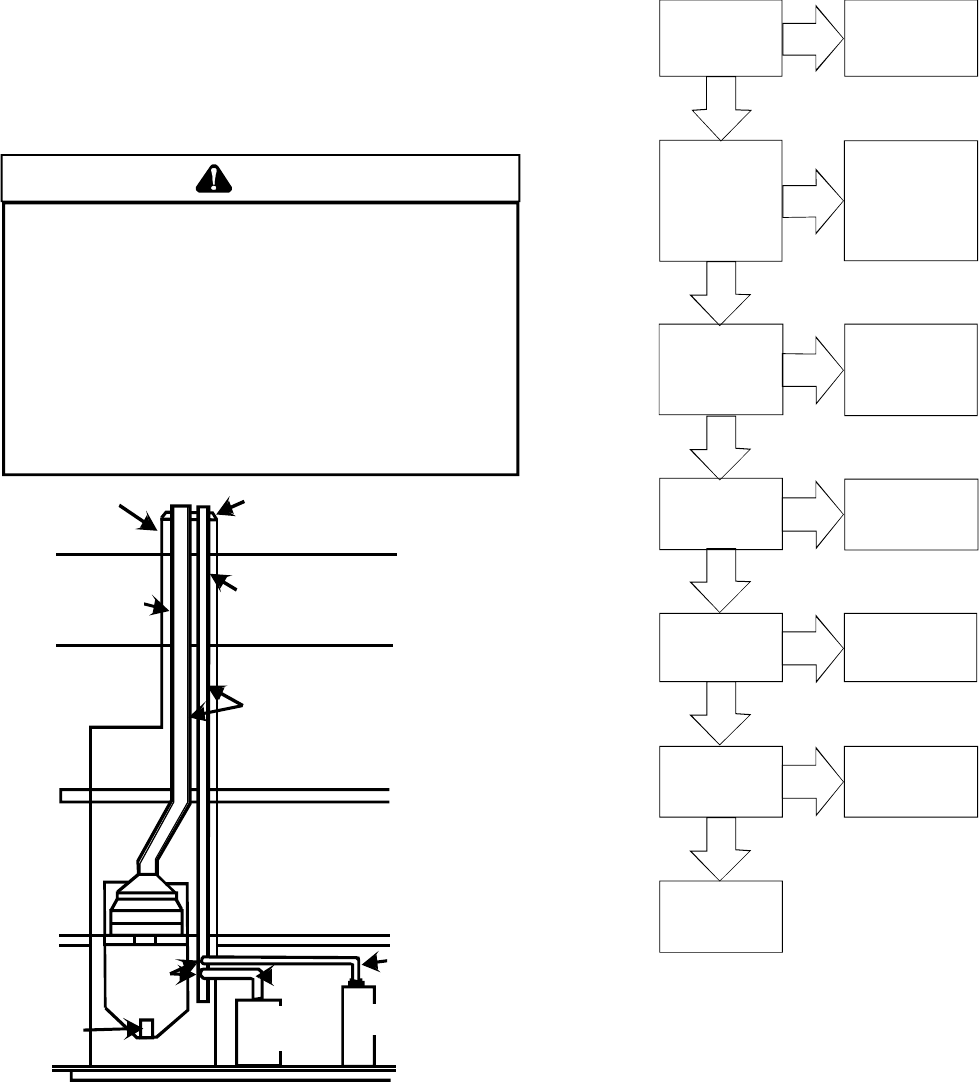

VII. EXTERIOR MASONRY CHIMNEYS -

CATEGORY I FURNACES ONLY

An exterior masonry chimney is defined as a “Masonry chimney

exposed to the outdoors on one or more sides below the roof

line.” The ability to use a clay lined masonry chimney depends

on a parameter not associated with interior chimneys. This variable

is the geographic location of the installation. Researchers have

discovered that the winter design temperatures have a direct

impact on the suitability of this type of venting. In most situations,

the existing masonry chimneys will require a properly sized metallic

liner.

WARNING

P

OSSIBILITY OF PROPERTY DAMAGE, PERSONAL INJURY OR DEATH

DAMAGING CONDENSATION CAN OCCUR INSIDE MASONRY CHIMNEYS WHEN A

SINGLE FAN ASSISTED

C

ATEGORY

I

APPLIANCE (80%

AFUE

FURNACE) IS

VENTED WITHOUT ADEQUATE DILUTION AIR.

D

O NOT CONNECT AN 80%

FURNACE TO A MASONRY CHIMNEY UNLESS THE FURNACE IS COMMON VENTED

WITH A DRAFT HOOD EQUIPPED APPLIANCE OR THE CHIMNEY IS LINED WITH A

METAL LINER OR

T

YPE

B

METAL VENT.

A

LL INSTALLATIONS USING MASONRY

CHIMNEYS MUST BE SIZED IN ACCORDANCE WITH THE APPROPRIATE VENTING

TABLES.

I

F AN 80% FURNACE IS COMMON VENTED WITH A DRAFT HOOD

EQUIPPED APPLIANCE, THE POTENTIAL FOR CONDENSATION DAMAGE MAY

STILL EXIST WITH EXTREMELY COLD CONDITIONS, LONG VENT CONNECTORS,

EXTERIOR CHIMNEYS, OR ANY COMBINATION OF THESE CONDITIONS.

T

HE

RISK OF CONDENSATION DAMAGE IS BEST AVOIDED BY USING THE MASONRY

CHIMNEY AS A PATHWAY FOR PROPERLY SIZED METAL LINER OR

T

YPE

B

METAL VENT.

Wash

Crown

Clay Tile Size: 8" x 8" x12"

(Each x 24" Length)

Clay Tile Size Generally

12" x 12" (24" Length)

1/2" to 1" Air Space

Second Floor

First Floor

Attic Floor

Roof Line

Throat

Damper

Breech

Clean Out

Fan Assisted

Forced Air

Furnace

Natural Draft

Water Heater

Water Heater

Vent Connector

Basement Floor

F.A.F. Vent

Connector

Figure 8 - Typical Multiple Flue Clay Tile Chimney

CHECKLIST SUMMARY

This checklist serves as a summary of the items to be checked

before venting an 80+ furnace into a masonry chimney. In addition,

we recommend that a qualified serviceman use this checklist to

perform a yearly inspection of the furnace venting system.

This checklist is only a summary. For detailed information on each

of the procedures mentioned, see the paragraph referenced with

each item.

This inspection is based upon a draft topical report, “Masonry

Chimney Inspection and Relining”, issued by the Gas Research

Institute. While not yet finalized, we believe this report represents

the best information on this subject which is currently available.

Proper Chimney

Termination?

(Check 1)

Line, terminate with

listed vent cap

(Fix 1)

No

Yes

Chimney channel

free of solid and

liquid fuel

appliances?

(Check 2)

Change venting

arrangements

(Fix 2)

No

Yes

Crown in good

condition

(Check 3)

Rebuild crown

(Fix 3)

and/or Reline

(Fix 4)

Yes

No

Yes

No

No

Reline

(Fix 4)

Reline

(Fix 4)

Cleanout free of

debris?

(Check 4)

Liner in good

condition?

(Check 5)

Yes

Yes

No

Reline

(Fix 4)

Dilution air

available?

(Check 6)

Complete the

installation.

(Check 7)

CHECK 1 - PROPER CHIMNEY TERMINATION.

A masonry chimney used as a vent for gas fired equipment must

extend at least three feet above the highest point where it passes

through the roof. It must extend at least two feet higher than any

portion of a building within a horizontal distance of 10 feet. In

addition, the chimney must terminate at least 3 feet above any

forced air inlet located within 10 feet. The chimney must extend at

least five feet above the highest connected equipment draft hood

outlet or flue collar.

If the chimney does not meet these termination requirements, but

all other requirements in the checklist can be met, it may be

possible for a mason to extend the chimney. If this will not be

practical, see Fix 1.